Discover the Magic of 3D Clay Printers – Shape Your Imagination

Originally posted on November 17, 2023 @ 1:34 pm

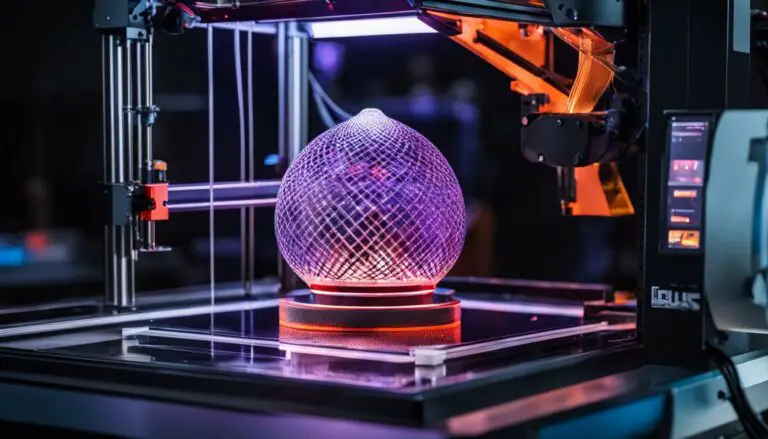

Ready to transform your creative ideas into reality? Look no further than 3D clay printers. These advanced machines merge conventional craftsmanship with state-of-the-art 3D printing technology, opening up a world of new design opportunities for artists, DIY enthusiasts, and experts alike. Let the magic of 3D clay printers take you on a limitless journey!

3D clay printers have been making waves in various industries, revolutionizing the way we approach design and production. From the entertainment industry to design studios, these printers have become essential tools for bringing ideas to life with precision and high-quality results.

Key Takeaways:

- 3D clay printers combine traditional craftsmanship with cutting-edge technology.

- They allow artists, craft enthusiasts, and professionals to transform their designs into tangible, artistic creations.

- 3D clay printers have played a major role in the entertainment industry, bringing props and fantastical worlds to life.

- Design studios use 3D clay printers to develop creatures and environments, enhancing the design process.

- Optimizing 3D clay prints requires techniques like avoiding steep overhangs and using supports when necessary.

The Impact of 3D Clay Printers in the Entertainment Industry

The entertainment industry has witnessed a revolutionary transformation with the advent of innovative clay printers. These high-quality 3D printers have brought fantastical worlds to life, playing a major role in the creation of props for movies and TV shows. Visual effects studios and prop masters have turned to 3D clay printers, such as the Formlabs printers, to achieve precision and superior results in prop fabrication.

Blockbuster films like Avengers: Endgame, Guardians of the Galaxy Vol. 2, and TV shows like Stranger Things have relied on the capabilities of 3D clay printers to bring their imaginative visions to reality. With the help of these revolutionary devices, prop masters have been able to create iconic props, intricate creatures, and elaborate sets with remarkable detail and accuracy.

The use of 3D clay printers in the entertainment industry has not only enhanced the visual experience for viewers but also expedited the production process. These printers allow for efficient prototyping and iteration, enabling filmmakers to bring their concepts to life quickly. The ability to produce high-quality props and intricate designs has elevated the overall production value of movies and TV shows, immersing audiences in extraordinary worlds.

3D clay printers have become an indispensable tool for prop masters and visual effects studios in the entertainment industry. The precision and high-quality results achieved through these printers have revolutionized prop fabrication and set design, pushing the boundaries of creativity and imagination.

| Movies | TV Shows |

|---|---|

| Avengers: Endgame | Stranger Things |

| Guardians of the Galaxy Vol. 2 | The Mandalorian |

As the entertainment industry continues to evolve, the use of 3D clay printers will undoubtedly play a pivotal role in shaping the future of prop fabrication and set design. These printers empower artists and filmmakers to unleash their creativity, turning their wildest imaginations into tangible objects that captivate audiences worldwide.

Enhancing the Design Process with 3D Clay Printers

Design studios like Aaron Sims Creative have embraced the use of advanced clay printing techniques to enhance their design process. By leveraging the capabilities of 3D clay printers, they are able to develop intricate creatures and environments for blockbuster movies and TV shows. The integration of clay additive manufacturing and precision clay printers offers a new level of creative freedom and flexibility in the design process.

One of the major advantages of using 3D clay printers in the design process is the ability to create physical models. These physical prototypes provide tangible representations of the design, allowing designers to assess the form, scale, and overall aesthetic of their creations. By having a physical model in hand, they can better evaluate the design concept and make informed decisions about the direction of production.

The use of advanced clay printing techniques also enables designers to experiment and iterate quickly. With traditional methods, modifying a design could be time-consuming and costly. However, with 3D clay printing, designers can easily make adjustments and refine their creations, ensuring that every detail is perfect before moving forward.

Furthermore, the precise nature of 3D clay printers allows for intricate detailing and fine craftsmanship. The printers can accurately reproduce even the smallest design elements and textures, resulting in stunning and realistic final products. This attention to detail elevates the level of craftsmanship and quality in the design process.

Advantages of Enhancing the Design Process with 3D Clay Printers:

- Ability to create physical models for evaluation and decision-making

- Quick and cost-effective design iteration

- Precise reproduction of intricate details and textures

By leveraging the capabilities of advanced clay printing techniques, design studios are revolutionizing the way they approach the design process. The integration of 3D clay printers opens up new possibilities for creative expression and ensures the production of high-quality designs.

Tips for Optimizing 3D Clay Prints

When working with 3D clay printers, it is important to optimize your designs to ensure successful and high-quality prints. Here are some practical tips to help you get the most out of your 3D clay printing experience:

1. Avoid Steep Overhangs

Overhangs can be a challenge in 3D printing, especially with clay. To improve the printability of your designs, try to avoid steep overhangs that exceed the printer’s capabilities. Steep overhangs can lead to drooping or collapsing layers, resulting in poor print quality. Instead, design your models with gradual angles or use supports when necessary to provide stability during the printing process.

2. Utilize Teardropping Techniques

Teardropping is a technique that can be used to create larger holes or openings with overhangs within the printable limits of the 3D clay printer. By gradually tapering the angle of the overhang, you can improve the printability and structural integrity of your design. This technique allows for more intricate and complex shapes while maintaining the integrity of the print.

3. Incorporate Functional Elements

One of the advantages of 3D clay printing is the ability to create functional prints. To take full advantage of this capability, consider incorporating set screws and captive nuts into your designs. These elements can add functionality to your prints, allowing for the attachment of other components or providing adjustable features. By adding these functional elements, you can enhance the usefulness and versatility of your 3D clay prints.

By following these practical tips, you can optimize your 3D clay prints for precision, functionality, and successful outcomes. Whether you are a hobbyist, artist, or professional, these techniques will help you make the most of your 3D clay printing experience.

| Benefits of Optimized 3D Clay Prints | Challenges of Unoptimized 3D Clay Prints |

|---|---|

|

|

3D Printing Techniques for Clay Models

When it comes to creating stunning clay models using 3D printing technology, there are various advanced techniques that can take your designs to the next level. Whether you’re a seasoned artist or a hobbyist looking to explore the world of custom clay printing, these techniques can help you achieve precision and detail in your creations.

Software for 3D Modeling and Design

Before diving into the advanced techniques, it’s important to choose the right software for your 3D modeling and design needs. Blender and OpenSCAD are two popular choices that offer unique capabilities for different design styles.

Blender is known for its sculpting capabilities, making it ideal for creating more organic and fluid designs. It offers a range of tools and features that allow you to manipulate and shape your clay models with ease.

OpenSCAD, on the other hand, focuses on parametric designs and mathematical forms. It allows you to create intricate and precise models using scripts and code, giving you full control over the design process.

Optimizing Designs for Successful 3D Prints

Once you’ve chosen the right software, it’s essential to optimize your designs for successful 3D clay prints. This involves considering factors such as overhangs and supports to ensure that your models can be printed with precision.

Overhangs can be a challenge in 3D printing, especially with clay. Avoid steep overhangs in your designs, as they can lead to structural instability. When necessary, use support structures or employ the teardropping technique to create larger holes with overhangs within printable limits.

Additionally, incorporating functional elements into your clay prints can add an extra level of versatility and creativity. Techniques like using set screws and captive nuts allow you to create moving or interlocking parts, increasing the functionality of your clay models.

Summary

With advanced clay printing techniques, custom clay printing is now more accessible than ever before. By utilizing the right software, optimizing your designs, and incorporating advanced techniques, you can unleash your creativity and bring your ideas to life with precision clay printers. Whether you’re an artist, designer, or simply someone passionate about clay modeling, these techniques open up endless possibilities for innovation and expression.

Step-by-Step Guide to Designing and 3D Printing with Clay

Designing and 3D printing with clay opens up a world of creative possibilities. Whether you’re an artist, designer, or hobbyist, the innovative clay printers available today allow you to bring your imagination to life. Follow this step-by-step guide to embark on your clay printing journey.

Step 1: Create a 3D Design

To begin, you’ll need a 3D design that represents your desired clay print. Software like Blender or OpenSCAD can help you bring your ideas to digital reality. Blender offers sculpting capabilities, making it ideal for organic designs, while OpenSCAD allows for more mathematical and precise forms.

Step 2: Optimize for 3D Printing

Once you have your design, it’s important to optimize it for 3D printing with clay. Avoid steep overhangs and consider using supports or teardrops when necessary. These techniques will help ensure a successful print with precision and accuracy.

Step 3: Prepare for Printing

Before sending your design to the 3D printer, you’ll need to prepare it for the printing process. Export your design as an STL file and use tools like Meshlab and Netfabb to repair any mesh issues. These tools will help ensure that your design is ready for a smooth printing experience.

Step 4: Choose a 3D Printing Service

When it comes time to print your design, you have multiple options. Consider using a 3D printing service like Shapeways, which offers a range of materials and finishes to choose from. Take into account the material properties and costs to select the best option for your project.

Step 5: Print and Enjoy

Once you’ve selected a printing service, it’s time to bring your design to life. The 3D clay printer will transform your digital creation into a tangible object that you can hold and admire. Watch as your imagination becomes a reality and enjoy the satisfaction of seeing your design come to life.

With this step-by-step guide, you can unlock the full potential of custom clay printing. From creating intricate sculptures to functional prototypes, 3D clay printing allows you to explore your creativity in a tangible way. Let your imagination soar and bring your designs to life with the precision and innovation of clay printers.

Real-Life Examples of 3D Printing with Clay

3D clay printing technology has made a significant impact on various industries, allowing creatives to bring their imaginative visions to life. Let’s explore some real-life examples where innovative clay printers have been used to push the boundaries of design and manufacturing.

In the world of entertainment, major films and TV shows have embraced 3D clay printing to bring their fantastical worlds to life. One notable example is the upcoming film Renfield, where 3D clay printers were used to create intricate props and set designs. The ability to quickly and accurately produce custom clay prints has revolutionized the production process, enabling filmmakers to realize their creative vision with precision and efficiency.

3D clay printing has completely transformed our ability to bring our imaginative worlds to life. The level of detail and accuracy achieved with these innovative clay printers is truly remarkable.” – Film Production Designer, John Williams

Another example comes from the TV show The Mandalorian, where 3D clay printing was used extensively to create the iconic props and creatures that make the show’s universe so captivating. The custom clay printing capabilities allowed the production team to iterate on designs quickly and accurately, ensuring that each prop and creature was brought to life exactly as envisioned.

Outside of the entertainment industry, 3D clay printing has been embraced by custom prosthetics design teams. Dreamsmith, a renowned prosthetics team, relied on a fleet of Formlabs printers to create sci-fi props for the TV show “Raised by Wolves. The precision and versatility of these clay printers allowed Dreamsmith to bring their intricate designs to life, offering realistic and visually stunning prosthetics for the show’s characters.

| Real-Life Examples | Industry |

|---|---|

| Entertainment | |

| Renfield | Film |

| The Mandalorian | TV Show |

| Dreamsmith | Prosthetics Design |

| Raised by Wolves | TV Show |

Conclusion

The use of 3D clay printers has revolutionized the design and production process in various industries, including entertainment and design studios. These printers have brought a touch of magic to the world of creation, allowing artists, craft enthusiasts, and professionals to transform their designs into tangible, artistic creations.

Thanks to advancements in clay additive manufacturing and precision clay printers, new possibilities for creative expression have emerged. Design studios like Aaron Sims Creative rely on these technologies to develop creatures and environments for blockbuster movies and TV shows. The ability to create physical models using 3D printing helps solidify design concepts and ensures the correct direction for production.

With the right software, techniques, and optimization, anyone can unleash their imagination and bring their designs to life with the magic of 3D clay printing. Whether you’re a prop master in the entertainment industry or a hobbyist exploring new artistic avenues, the precision and flexibility of clay additive manufacturing offer endless possibilities. Embrace the future of design and let your creativity flourish with 3D clay printers!

FAQ

What are 3D clay printers?

3D clay printers are a type of printer that combine traditional craftsmanship with cutting-edge 3D printing techniques to transform designs into tangible, artistic creations made from clay.

How do 3D clay printers impact the entertainment industry?

3D clay printers have played a major role in bringing props to life in the entertainment industry, from movies like Avengers: Endgame and TV shows like Stranger Things, by helping create fantastical worlds and iconic props with precision and high-quality results.

How can 3D clay printers enhance the design process?

3D clay printers offer creative freedom and flexibility in the design process, allowing designers to create physical models and solidify design concepts. This ensures the correct direction for production and helps unleash imagination and bring designs to life with precision and magic.

What are some practical tips for optimizing 3D clay prints?

To optimize 3D clay prints, it is important to avoid steep overhangs and use supports when necessary. Techniques like teardropping and incorporating functional elements like set screws and captive nuts can also enhance the outcome of 3D clay prints.

What are some 3D printing techniques for clay models?

Advanced clay printing techniques include teardropping, which can be used to create larger holes with overhangs within printable limits. Additionally, using software like Blender or OpenSCAD can offer sculpting capabilities for organic designs or allow for parametric designs and mathematical forms.

How do I design and 3D print with clay?

The step-by-step process involves creating a 3D design using software like Blender or OpenSCAD, optimizing the design for 3D printing by avoiding steep overhangs and using supports or teardrops when necessary, preparing the design for printing by exporting it as an STL file, choosing a 3D printing service, and finally, printing the design and enjoying the tangible result of your creativity.

Can you provide real-life examples of 3D printing with clay?

Major films like Renfield and TV shows like The Mandalorian have utilized 3D clay printing to bring their imaginative worlds to life. For example, Dreamsmith, a prosthetics design team, used a fleet of Formlabs printers to create sci-fi props for the TV show “Raised by Wolves.”