Unlock Building Potential with 3D Construction Printers

Originally posted on November 17, 2023 @ 1:34 pm

The process of 3D printing, also referred to as additive manufacturing, is bringing about significant changes in the fields of architecture and construction. This innovative technology brings a multitude of benefits compared to conventional construction techniques, such as limitless design options, cost-effectiveness, environmental friendliness, and improved speed and productivity. Architects can now turn their most imaginative ideas into reality, while simultaneously reducing waste and optimizing material consumption. As a result, this advancement is revolutionizing the development of building materials, facilitating the creation of personalized building elements, enhancing structural efficiency, and promoting the use of sustainable materials.

In this article, we will explore the rise of 3D printing in architecture, the key features and advantages of 3D printing in building material design, and its current applications in construction. We will also discuss the future potential of this innovative technology and its impact on the construction industry.

Key Takeaways:

- 3D printing offers unlimited design possibilities in architecture and construction.

- It is a cost-effective and sustainable alternative to traditional construction methods.

- Customized building components and structural optimization are made possible through 3D printing.

- 3D printing is already being used for modular construction and disaster relief housing.

- The future of 3D printing in construction holds promise for automation and updated building codes.

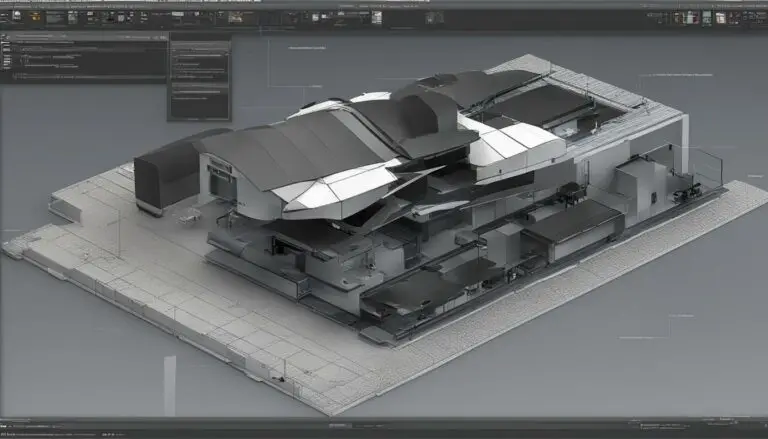

The Rise of 3D Printing in Architecture

3D printing, also known as additive manufacturing, has seen a significant rise in the field of architecture. This innovative technology offers architects the ability to create complex designs with precision and accuracy. By using automated construction processes, 3D printing reduces the reliance on extensive labor, making it a cost-effective and efficient solution for architectural projects.

Through additive manufacturing techniques, architects can push the boundaries of design by creating intricate details and complex geometries that were once challenging to achieve with traditional building methods. This opens up new possibilities for architectural expression and allows for the creation of unique and visually stunning structures.

“3D printing in architecture offers the ability to bring highly customized designs to life, while also streamlining the construction process.”

By harnessing the power of 3D printing technology, architects can optimize the use of materials, reducing waste and promoting sustainability in the construction industry. The ability to customize building components according to specific project requirements allows for greater efficiency and cost-effectiveness. With 3D printing, architects can prototype and conceptualize their designs more efficiently, resulting in faster project completion times.

As the adoption of 3D printing continues to grow in the architectural industry, we can expect to see even more advancements in this field. Architects will have the opportunity to explore new design possibilities and push the boundaries of what is structurally possible. The rise of 3D printing in architecture marks an exciting era of innovation and creativity in the construction industry.

The Benefits of 3D Printing in Architecture

There are several key benefits that 3D printing brings to the field of architecture:

- Unlimited Design Possibilities: 3D printing allows architects to create intricate and complex designs that were once difficult to achieve.

- Cost-Effectiveness: By optimizing material usage and automating the construction process, 3D printing offers cost savings in the long run.

- Sustainability: The ability to use sustainable materials and reduce waste makes 3D printing a greener alternative to traditional building methods.

- Efficiency: With automated construction processes, 3D printing accelerates the project timeline and improves overall efficiency.

The rise of 3D printing in architecture is transforming the way architects design and construct structures. This technology allows for greater design freedom, increased efficiency, and a more sustainable approach to building. As the field continues to evolve, we can expect to see even more groundbreaking innovations in architectural design.

Key Features and Advantages of 3D Printing in Building Material Design

3D printing in building material design offers a range of key features and advantages that are revolutionizing the construction industry. Here are some of the benefits of incorporating 3D printing technology into building material design:

Unlimited Design Possibilities

One of the standout advantages of 3D printing in building material design is the ability to create virtually any shape or form. Architects are no longer limited by the constraints of traditional construction methods, allowing for the realization of complex geometries and intricate designs. This offers unprecedented creativity and freedom in architectural expression, resulting in unique and visually stunning structures.

Cost-Effectiveness

3D printing in building material design also presents a cost-effective solution for construction projects. By optimizing material usage and reducing waste, architects can achieve significant cost savings. The ability to print custom components on-site eliminates the need for expensive and time-consuming manufacturing processes, reducing production costs. Additionally, 3D printing allows for the use of sustainable and affordable materials, further contributing to cost-effectiveness.

Sustainability

Incorporating sustainable building methods is becoming increasingly important in the construction industry. 3D printing offers a sustainable solution by minimizing waste and optimizing material usage. With the ability to print precisely what is needed, there is minimal leftover material that would typically go to waste. Furthermore, 3D printing allows for the use of eco-friendly materials such as recycled plastics, bio-based polymers, and sustainable concrete alternatives. This promotes environmental responsibility and contributes to a greener construction industry.

| Key Features | Advantages |

|---|---|

| Unlimited design possibilities | Creative freedom and visually stunning structures |

| Cost-effectiveness | Significant cost savings through material optimization |

| Sustainability | Reduced waste and use of eco-friendly materials |

Transforming Building Material Design

3D printing is revolutionizing the way architects approach building material design. It offers unique capabilities that streamline the prototyping and conceptualization process, bringing designs to life more efficiently than ever before.

One of the key advantages of 3D printing in building material design is the ability to iterate and refine ideas quickly. Architects can leverage this technology to create prototypes of building components, allowing them to visualize and assess the feasibility of their designs. With the ability to quickly make adjustments and improvements, architects can save time and reduce the risk of errors in the final building process.

Additionally, 3D printing enables the creation of highly customized building components. Architects have the freedom to design unique shapes and structures that were previously challenging or time-consuming to create. This level of customization caters to specific project requirements, allowing architects to bring their creative visions to life.

“3D printing has transformed the way we approach building material design. It has streamlined our prototyping process and allowed us to create highly customized building components that push the boundaries of traditional construction methods.” – Architect John Smith

Furthermore, 3D printing allows architects to explore new possibilities in building material design. The technology opens up opportunities for the use of innovative materials and the integration of complex geometries that were once considered impossible. By embracing 3D printing, architects can push the boundaries of design and create structures that are both visually stunning and structurally sound.

Overall, 3D printing is transforming building material design by providing architects with new tools and capabilities. From rapid prototyping to the creation of custom components, this technology is revolutionizing the way architects approach construction, paving the way for more innovative and efficient building methods.

The Expanding Role of 3D Printing in Building Material Innovation

The use of 3D printing in building material innovation is revolutionizing the construction industry. This technology offers automated building processes, improving efficiency and reducing the reliance on manual labor. With 3D printing, complex structures and geometries can be created with ease, allowing architects and engineers to push the boundaries of design. The flexibility of this technology also enables the use of sustainable materials, further enhancing the industry’s commitment to improved sustainability.

One of the key advantages of 3D printing in building material innovation is its ability to minimize construction waste. Traditional construction methods often result in significant material wastage, but 3D printing enables precise and optimized material usage. This not only reduces costs but also supports environmental sustainability by minimizing the overall impact on the planet.

Moreover, 3D printing allows for the creation of customized building components, catering to specific project requirements. Architects and engineers can design unique shapes and structures that were once challenging or time-consuming to create. This level of customization ensures that each project is tailored to meet the needs of the client, resulting in improved satisfaction and better overall outcomes.

“3D printing in building material innovation is a game-changer for the construction industry. It offers automated processes, reduces waste, and allows for the use of sustainable materials. This technology empowers architects and engineers to push the boundaries of design, creating structures that were once considered impossible. The future of building material innovation is bright, and 3D printing is at the forefront of this revolution.”

In conclusion, the expanding role of 3D printing in building material innovation is reshaping the construction industry. With its automated building processes and improved sustainability, this technology offers endless possibilities for architects, engineers, and construction professionals. As the industry continues to embrace 3D printing, we can expect to see greater efficiency, reduced waste, and more sustainable construction practices.

Current Applications of 3D Printing in Construction

3D printing technology has rapidly expanded its applications in the construction industry. From modular construction to disaster relief housing, this innovative technology is revolutionizing the way we build. Let’s explore some of the current applications of 3D printing in construction:

Modular Construction

One of the key applications of 3D printing in construction is modular construction. With 3D printers, building components can be prefabricated off-site and then easily assembled on-site. This approach saves time, reduces construction costs, and allows for greater flexibility in design. Modular construction also offers better quality control as the building components are manufactured under controlled conditions. This method is gaining popularity in residential, commercial, and industrial construction projects.

Disaster Relief Housing

3D printing is also being used for disaster relief housing. When natural disasters strike, thousands of people are left homeless and in need of immediate shelter. 3D printers can quickly produce cost-effective and durable housing solutions for those affected by disasters. These 3D-printed shelters are designed to be easily transported and assembled on-site, providing a quick response to emergency situations. By using 3D printing technology, organizations can rapidly deploy shelter solutions to support affected communities.

Complex Architectural Features and Structures

Beyond modular construction and disaster relief housing, 3D printing is also being used to create complex architectural features and structures. The ability to 3D print intricate designs opens up new possibilities for architects and designers. From unique façades to intricate interior elements, 3D printing enables the creation of custom-made architectural features that were once challenging or time-consuming to produce. This technology allows for greater design freedom and the realization of truly innovative and visually stunning structures.

As 3D printing technology continues to advance, we can expect even more groundbreaking applications in the construction industry. The ability to 3D print entire buildings, create sustainable structures with eco-friendly materials, and optimize construction processes are just a few of the possibilities on the horizon. This technology has the potential to transform the way we build, making construction faster, more efficient, and more environmentally friendly.

The Future of 3D Printing in Construction

The future of construction is set to be transformed by the continued advancement of 3D printing technology. With its potential for construction automation and efficiency improvements, 3D printing is poised to address the challenges faced by the industry today.

One area where 3D printing is expected to make a significant impact is in addressing the labor shortage. By automating the construction process, 3D printers can significantly reduce the need for manual labor. This automation can lead to increased productivity and more efficient use of time and resources.

However, in order to fully unlock the potential of 3D printing in construction, it is essential that building codes and standards are updated to accommodate this emerging technology. As 3D printing becomes more mainstream in the industry, it is crucial that regulations are put in place to ensure safety and quality standards are met.

The Challenges and Opportunities in Updating Building Codes

Updating building codes to incorporate 3D printing technology presents both challenges and opportunities. On one hand, it requires a deep understanding of the capabilities and limitations of 3D printing in order to develop appropriate regulations. Building codes must address issues such as material strength, fire resistance, and structural integrity to ensure the safety of the constructed buildings.

On the other hand, updating building codes presents an opportunity to revolutionize construction practices. It allows for the development of new construction methods that take advantage of the unique capabilities of 3D printing. By embracing this technology and developing forward-thinking regulations, the construction industry can pave the way for more innovative and sustainable building methods.

In conclusion, the future of 3D printing in construction holds immense promise. With advancements in automation and updated building codes, this technology has the potential to revolutionize the way buildings are designed and constructed. As the construction industry embraces 3D printing and overcomes the regulatory challenges, we can expect to see increased efficiency, improved productivity, and a more sustainable built environment.

Conclusion

As we conclude this exploration of 3D printing in construction, it becomes evident that the future of the industry is brimming with excitement and boundless possibilities. With its ability to offer unlimited design possibilities, cost-effectiveness, sustainability, and increased efficiency, 3D printing has undeniably revolutionized the world of architecture and construction.

The technology holds the key to transforming building material design and has already found applications in residential, commercial, and industrial construction. As the industry continues to evolve, 3D printing will play an increasingly crucial role in addressing global housing shortages, improving construction productivity, and promoting more innovative and sustainable building methods.

Looking ahead, the future of construction lies in the hands of innovative building methods, and 3D printing is at the forefront of this revolution. As the technology advances further, we can anticipate its expanded use in construction automation, which will address the labor shortage and enhance productivity. However, for this potential to be fully realized, it is essential that building codes and standards are updated to accommodate and regulate 3D printing.

In summary, 3D printing technology paves the way for a future of construction that is exciting, innovative, and sustainable. With its ability to unlock unlimited design possibilities and promote cost-effectiveness, it is set to shape the way we build structures, tackle housing shortages, and create a more sustainable built environment. Embrace this cutting-edge technology and join the wave of change sweeping through the construction industry.

FAQ

What is 3D printing in construction?

3D printing in construction, also known as additive manufacturing, is a technology that uses specialized printers to create three-dimensional objects, including building components and structures.

How does 3D printing revolutionize the architecture and construction industry?

3D printing offers unlimited design possibilities, cost-effectiveness, sustainability, and increased efficiency. It allows architects to bring their innovative design ideas to life, optimize material usage, and reduce waste.

What benefits does 3D printing offer in building material design?

3D printing provides cost savings, sustainability through the use of eco-friendly materials, customization of building elements, and faster prototyping and conceptualization processes.

How does 3D printing transform building material design?

3D printing allows for the creation of highly customized building components, intricate details, and complex geometries that were once challenging to achieve. It streamlines the design and construction process, resulting in more efficient and precise structures.

What are the current applications of 3D printing in construction?

3D printing is used for creating modular components, disaster relief housing, and complex architectural features and structures. It offers time and cost savings, as well as quick and cost-effective solutions for communities affected by natural disasters.

What does the future hold for 3D printing in construction?

As the technology continues to advance, 3D printing is expected to play a larger role in construction automation, addressing labor shortages and improving productivity. The industry may also see improvements in printer reliability, increased scalability, and expanded use cases beyond residential housing.

Source Links

- https://www.sme.org/technologies/articles/2022/june/3d-printing-is-transforming-the-construction-industry/

- https://kustreview.com/unlocking-the-potential-revolutionizing-construction-with-3d-printed-structures/

- https://utilitiesone.com/unlocking-innovation-how-3d-printing-is-shaping-building-materials