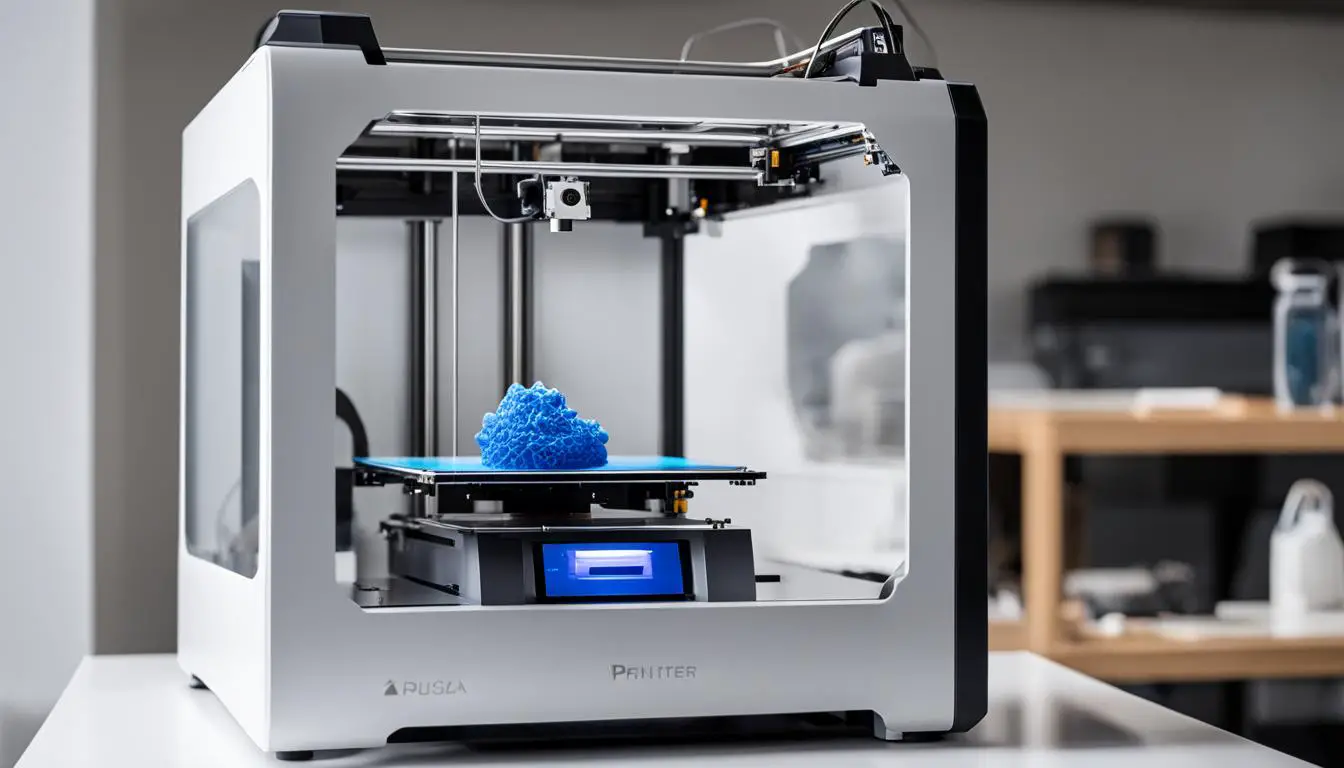

Unlock Possibilities: What Can You Do with 3D Printers?

Originally posted on November 17, 2023 @ 1:34 pm

Please rephrase the following passage without changing its original meaning or intent. Do not remove any embedded links. If you are unable to do so, please reply with the following error message: “Unable to process the request due to encountered difficulties.”

Welcome to the world of 3D printing, where imagination knows no bounds! With this cutting-edge technology, you can embark on a journey of endless possibilities and transform your ideas into reality. From healthcare to fashion, 3D printers are revolutionizing various industries and unlocking new avenues for creativity and innovation. Let’s explore the incredible potential of what can be achieved with 3D printers.

Key Takeaways:

- 3D printing offers vast opportunities for customization, rapid prototyping, and the production of intricate designs.

- Industries such as healthcare, automotive, aerospace, architecture, and fashion can benefit immensely from 3D printing.

- In the medical field, 3D printing enables the creation of affordable prosthetics, personalized healthcare devices, and even the potential for printing organs and tissues.

- Automotive and aerospace industries leverage 3D printing for prototyping, lightweight structures, and customized components to enhance performance and fuel efficiency.

- In architecture, 3D printing allows for the construction of complex structures, sustainable practices, and affordable housing solutions.

Changing Lives: 3D Printing in the Medical Field

3D printing has revolutionized the medical field, opening up new possibilities for personalized healthcare solutions and improving the lives of individuals. One of the significant benefits of 3D printing in the medical industry is the creation of customized prosthetics. With traditional manufacturing methods, prosthetics can be expensive and ill-fitting. However, 3D printing allows for the production of affordable and tailor-made prosthetics, enhancing the comfort and functionality for patients.

But the impact of 3D printing in healthcare doesn’t stop there. Researchers are also exploring the potential to print organs and tissues, which could potentially solve the organ shortage crisis and save numerous lives. Imagine a world where patients in need of organ transplants no longer have to wait for a suitable donor, but instead can receive a custom-made organ created specifically for them using 3D printing technology.

Another practical application of 3D printing in the medical field is the production of personalized healthcare devices. Surgeons can use 3D printers to create surgical guides, improving the accuracy of procedures and reducing the risk of complications. Patient-specific implants can also be produced, ensuring a better fit and reducing the chances of rejection. The versatility of 3D printing enables healthcare professionals to provide tailored solutions that were once unimaginable.

“The impact of 3D printing in the medical field is immense. It has enabled us to create life-changing solutions for our patients, from customized prosthetics to personalized healthcare devices. The possibilities are endless, and we are just scratching the surface of what this technology can do.”

– Dr. Emily Carter, Chief Medical Officer at XYZ Hospital

Table: Practical Applications of 3D Printing in the Medical Field

| Application | Description |

|---|---|

| Customized Prosthetics | 3D printing allows for the production of affordable and tailor-made prosthetics, improving comfort and functionality for patients. |

| Organ and Tissue Printing | Researchers are developing the technology to print organs and tissues, potentially solving the organ shortage crisis. |

| Personalized Healthcare Devices | Surgeons can use 3D printing to create surgical guides and patient-specific implants, improving accuracy and reducing complications. |

As the field of 3D printing continues to advance, the applications in the medical industry will only expand further. From personalized prosthetics to organ printing, this transformative technology has the potential to change countless lives and shape the future of healthcare. The continued research and development in this area hold immense promise for improving patient care and pushing the boundaries of what’s possible in medicine.

Transforming Industries: 3D Printing in Automotive and Aerospace

3D printing has become a game-changer in the automotive and aerospace industries, offering unique opportunities for innovation and customization. In the automotive industry, 3D printing has revolutionized the production of customized car parts and components. Companies can now create intricate designs and lightweight structures that were once challenging to achieve using traditional manufacturing methods. This technology not only allows for rapid prototyping but also enables the production of one-of-a-kind parts tailored to specific needs and specifications.

Similarly, in the aerospace industry, 3D printing has transformed the manufacturing process by enabling the creation of lightweight and complex components. Lightweight structures are crucial in aerospace as they enhance fuel efficiency and overall performance. With 3D printing, engineers can design and produce parts that are not only lighter but also more durable, ensuring the safety and reliability of aircraft. This technology has opened up new possibilities for innovation in the aerospace industry, reducing manufacturing costs and improving overall efficiency.

One of the key advantages of 3D printing in both industries is the ability to reduce waste and optimize resources. Traditional manufacturing often results in significant material waste, but with 3D printing, companies can optimize material usage, reducing costs and environmental impact. Moreover, 3D printing allows for on-demand production, eliminating the need for large inventories of spare parts and reducing lead times for repairs and maintenance.

Table: Comparison of 3D Printing in Automotive and Aerospace Industries

| Aspect | Automotive Industry | Aerospace Industry |

|---|---|---|

| Application | Customized car parts, rapid prototyping | Lightweight and complex components, fuel efficiency |

| Advantages | Cost-effective production, design flexibility | Enhanced fuel efficiency, improved performance |

| Resource Optimization | Reduced material waste, on-demand production | Reduced material waste, on-demand production |

| Challenges | Quality control, scalability | Stringent regulations, certification |

“3D printing has transformed the way we approach design and manufacturing in both the automotive and aerospace industries. It has provided us with the ability to create complex and lightweight structures, customized parts, and on-demand production. This technology has opened up new possibilities for innovation and improved efficiency, ultimately transforming these industries for the better.”

Looking ahead, the potential for 3D printing in automotive and aerospace industries remains vast. As the technology continues to advance, we can expect even more breakthroughs and applications. From reducing manufacturing complexity and costs to enabling sustainable practices, 3D printing is revolutionizing the way we think about production in these industries. It is an exciting time for automotive and aerospace professionals as they embrace the endless possibilities that 3D printing brings to the table.

Revolutionizing Construction: 3D Printing in Architecture

3D printing is revolutionizing the field of architecture and construction, offering endless possibilities for innovation, sustainability, and affordability. With the ability to create intricate and complex architectural structures with ease, 3D printing provides architects and designers with greater design freedom than ever before. Large-scale 3D printers can efficiently construct buildings, reducing construction time and costs. It’s a technology that is transforming the way we build our cities and reshape the future of architecture.

One of the key advantages of 3D printing in architecture is its contribution to sustainable construction practices. By utilizing eco-friendly materials and reducing waste, 3D printing minimizes the environmental impact of traditional construction methods. This technology enables architects to explore new design approaches, incorporating organic and curvilinear forms that were once challenging to achieve. The result is not only visually captivating architecture but also structures that are environmentally friendly.

One of the most exciting prospects of 3D printing in architecture is its potential to address the global housing crisis. With the ability to construct affordable and customizable housing solutions, 3D printing offers a promising alternative to traditional construction methods. By leveraging the advantages of 3D printing, such as reduced labor costs and faster construction time, it becomes possible to create affordable housing options that can meet the needs of underserved communities. It’s a technology that holds the potential to make homeownership more accessible and alleviate housing shortages around the world.

The table below highlights the benefits of 3D printing in architecture:

| Benefits of 3D Printing in Architecture |

|---|

| Greater design freedom |

| Reduced construction time and costs |

| Eco-friendly and sustainable construction practices |

| Customizable and affordable housing solutions |

With 3D printing’s ability to push the boundaries of architectural design, reduce construction time and costs, promote sustainability, and provide affordable housing solutions, it is clear that this technology is revolutionizing the field of architecture. As 3D printing continues to advance and become more widely adopted, we can expect to see even more innovative and inspiring architectural projects.

Redefining Fashion and Jewelry: Creative Uses for 3D Printing

3D printing has revolutionized the fashion and jewelry industries, offering endless opportunities for creative expression and customization. Designers can now create intricate and complex jewelry pieces that were once difficult or impossible to achieve using traditional methods. With 3D printing, the possibilities for unique and personalized fashion accessories are limitless.

One of the key advantages of 3D printing in the fashion industry is the ability to produce customized pieces. Fashion designers can now create bespoke items tailored to the specific preferences and measurements of their customers. From customized shoes and eyewear to one-of-a-kind accessories, 3D printing opens up new avenues for personalized expression.

Furthermore, 3D printing allows for the exploration of innovative materials and designs. Designers can experiment with a wide range of materials, including biodegradable and eco-friendly options, to create sustainable fashion pieces. The ability to print intricate and complex designs also opens up new possibilities for the creation of avant-garde and futuristic fashion statements.

Table: Examples of 3D Printed Jewelry and Fashion Accessories

| Jewelry | Fashion Accessories |

|---|---|

| Customized rings | 3D printed shoes |

| Intricate earrings | Personalized eyewear |

| Statement necklaces | Unique handbags |

In conclusion, 3D printing is revolutionizing the fashion and jewelry industries, pushing the boundaries of design and customization. With the ability to create personalized fashion accessories and experiment with innovative materials and designs, 3D printing offers endless possibilities for creative expression. The future of fashion and jewelry is being redefined by this exciting technology, allowing designers to bring their imaginations to life and offer truly unique pieces to their customers.

The Future of 3D Printing Jobs

As the field of 3D printing continues to advance and evolve, so does the demand for professionals who possess the necessary skills and knowledge to thrive in this industry. The future of 3D printing jobs is promising, offering a wide range of exciting career opportunities. Whether you have a background in engineering, software development, or law, there are various paths you can pursue within the realm of 3D printing.

Future Careers in 3D Printing

One of the most promising career paths in 3D printing is that of a 3D organ and prosthetic designer in the biomedical science field. With the potential to print organs and custom-made prosthetics, there is a growing demand for professionals who can design and create these life-changing devices. This career requires a strong understanding of human anatomy and the ability to use CAD software to design intricate and functional 3D models.

Another exciting career choice is becoming a 3D printing software developer. These professionals play a crucial role in optimizing 3D printing technology and creating user-friendly interfaces that make the technology accessible to a wider audience. Strong programming skills and a deep understanding of the intricacies of 3D printing are essential for success in this field.

As 3D printing becomes more widespread, the need for intellectual property (IP) and copyright lawyers specializing in this area will also increase. These professionals will play a vital role in protecting the rights of individuals and companies involved in 3D printing, ensuring that innovations are properly safeguarded. A strong background in intellectual property law and a solid understanding of 3D printing technology are key for aspiring lawyers in this field.

3D Printing Careers in Specialized Industries

In addition to these broad career paths, there are also specialized roles within specific industries. For example, the automotive industry will require 3D printing auto mechanics and engineers who can work with advanced materials and create complex components for vehicles. These professionals will need a deep understanding of both automotive engineering principles and the intricacies of 3D printing technology.

Similarly, the aerospace industry will rely on 3D printing experts to design and create lightweight and high-performance components for aircraft and spacecraft. This field requires a combination of engineering knowledge and a deep understanding of the unique challenges and requirements of aerospace applications.

Overall, the future of 3D printing jobs is bright and full of opportunities. Whether you’re interested in designing life-changing medical devices, developing cutting-edge software, protecting intellectual property, or working in specialized industries like automotive or aerospace, there is a place for you in the world of 3D printing.

| Career Path | Required Skills |

|---|---|

| 3D Organ and Prosthetic Designer | Knowledge of human anatomy, CAD design skills |

| 3D Printing Software Developer | Programming skills, deep understanding of 3D printing technology |

| 3D Printing IP and Copyright Lawyer | Background in intellectual property law, understanding of 3D printing technology |

| 3D Printing Auto Mechanic and Engineer | Automotive engineering knowledge, expertise in working with advanced materials |

| 3D Printing Specialist in Aerospace Industry | Aerospace engineering knowledge, understanding of aerospace application requirements |

Choosing the Right 3D Printing Service Provider

When it comes to 3D printing, choosing the right service provider is crucial for the success of your projects. Whether you’re a business or an individual, finding a 3D printing service provider that can meet your specific needs is essential. Here are a few factors to consider when making your decision.

Expertise and Experience

One of the most important factors to consider is the expertise and experience of the service provider. Look for a company that has a proven track record in the industry and a portfolio that showcases their capabilities. You want to work with professionals who understand the complexities of 3D printing and can provide guidance and support throughout the process.

Technology and Equipment

Another important consideration is the technology and equipment the service provider uses. Different projects may require different types of printers and materials. Ensure that the provider has the necessary technology and equipment to meet your specific requirements. This includes the ability to work with a wide range of materials and produce high-quality prints.

Material Options

The variety of materials available for 3D printing is constantly expanding. Depending on your project, you may need specific materials with certain properties, such as strength, flexibility, or heat resistance. Make sure the service provider offers a range of material options that align with your project’s needs. This will ensure that you get the desired results and maximize the potential of 3D printing.

Choosing the right 3D printing service provider can make all the difference in the success of your projects. By considering factors such as expertise and experience, technology and equipment, and material options, you can ensure that you partner with a provider who can deliver high-quality prints and meet your specific needs.

Conclusion

The possibilities of what you can do with 3D printers are truly remarkable. From creating customized medical devices and prosthetics to revolutionizing industries like automotive and aerospace, 3D printing offers endless opportunities for innovation and creativity.

With 3D printing, you can bring your innovative ideas to life and explore new frontiers of design and manufacturing. The ability to produce intricate and complex structures with ease opens up a world of possibilities for designers, engineers, and creative individuals.

As the technology continues to advance, the uses of 3D printers will only expand. From personalized fashion accessories to sustainable construction solutions, the potential applications are limited only by your imagination. Whether you’re a professional in a specific industry or an enthusiast looking for a new hobby, 3D printing can unlock a whole new world of opportunity.

So go ahead, embrace the power of 3D printing and discover the innovative ideas and uses that await you. Let your creativity soar and take advantage of the endless possibilities that this technology has to offer.

FAQ

What industries can benefit from 3D printing?

3D printing has the potential to revolutionize various industries, including healthcare, automotive, aerospace, architecture, and fashion.

How is 3D printing changing the medical field?

3D printing allows for the creation of affordable and customized prosthetics, personalized healthcare devices, and the potential to print organs and tissues in the future.

In what ways is 3D printing used in the automotive and aerospace industries?

3D printing is used for prototyping, customized spare parts, lightweight components, and complex structures to improve fuel efficiency and performance.

How is 3D printing transforming the field of architecture and construction?

3D printing enables the creation of intricate and complex architectural structures, large-scale construction, and the use of sustainable materials for more environmentally friendly practices.

What impact does 3D printing have on the fashion and jewelry industries?

3D printing allows for the creation of intricate and customized jewelry pieces, as well as personalized fashion accessories such as shoes and eyewear.

What are some future careers in 3D printing?

Future careers in 3D printing include 3D organ and prosthetic designers, 3D printing software developers, 3D printing IP and copyright lawyers, and 3D printing mechanics and engineers.

What factors should be considered when choosing a 3D printing service provider?

It is important to consider the provider’s expertise and experience in your industry, the technology and equipment they use, and the available material options that meet your specific needs.

What are the possibilities of what can be done with 3D printers?

The possibilities of what can be achieved with 3D printers are vast and continue to expand, offering endless opportunities for innovation, customization, and creative expression.