Revolutionize Your Production with Desktop Metal 3D Printers

Originally posted on November 17, 2023 @ 1:32 pm

Introducing the next generation of manufacturing with Desktop Metal 3D printers. These revolutionary machines offer state-of-the-art technology at accessible prices, revolutionizing the production of metal parts. Whether you’re an entrepreneur or an engineer in an industrial environment, Desktop Metal has the ideal solution to meet your specific requirements.

3D printing technology, also known as additive manufacturing, has been revolutionizing industries across the globe. And now, with Desktop Metal’s state-of-the-art printers, you can bring the power of metal additive manufacturing right to your desktop. No longer will you require expensive industrial facilities or rely on traditional manufacturing methods.

Desktop Metal offers two incredible systems: the DM Studio and DM Production. Both systems provide safe, precise, and cost-effective metal 3D printing for prototyping and mass production. The DM Studio System is ten times more affordable than existing technology, while the DM Production System is 100 times faster than laser-based additive manufacturing systems.

Key Takeaways:

- Desktop Metal 3D printers offer affordable and precise metal 3D printing.

- Bound Metal Deposition (BMD) technology ensures accurate and repeatable parts.

- The DM Studio System is office-friendly, eliminating the need for hazardous powders and lasers.

- The DM Production System is ideal for high-resolution metal parts production.

- Desktop Metal’s systems provide faster printing speeds and reduced post-processing requirements.

The Desktop Metal Studio System

The Desktop Metal Studio System is revolutionizing the world of office-friendly metal 3D printing. With its innovative technology and affordable price point, it offers engineers and designers the opportunity to bring their ideas to life with ease and precision.

Unlike traditional metal 3D printing processes, the Desktop Metal Studio System eliminates the need for hazardous powders, lasers, or cutting tools. Instead, it utilizes Bound Metal Deposition (BMD) to create complex geometries of metal 3D printed parts. This makes it a safer and more accessible option for rapid prototyping.

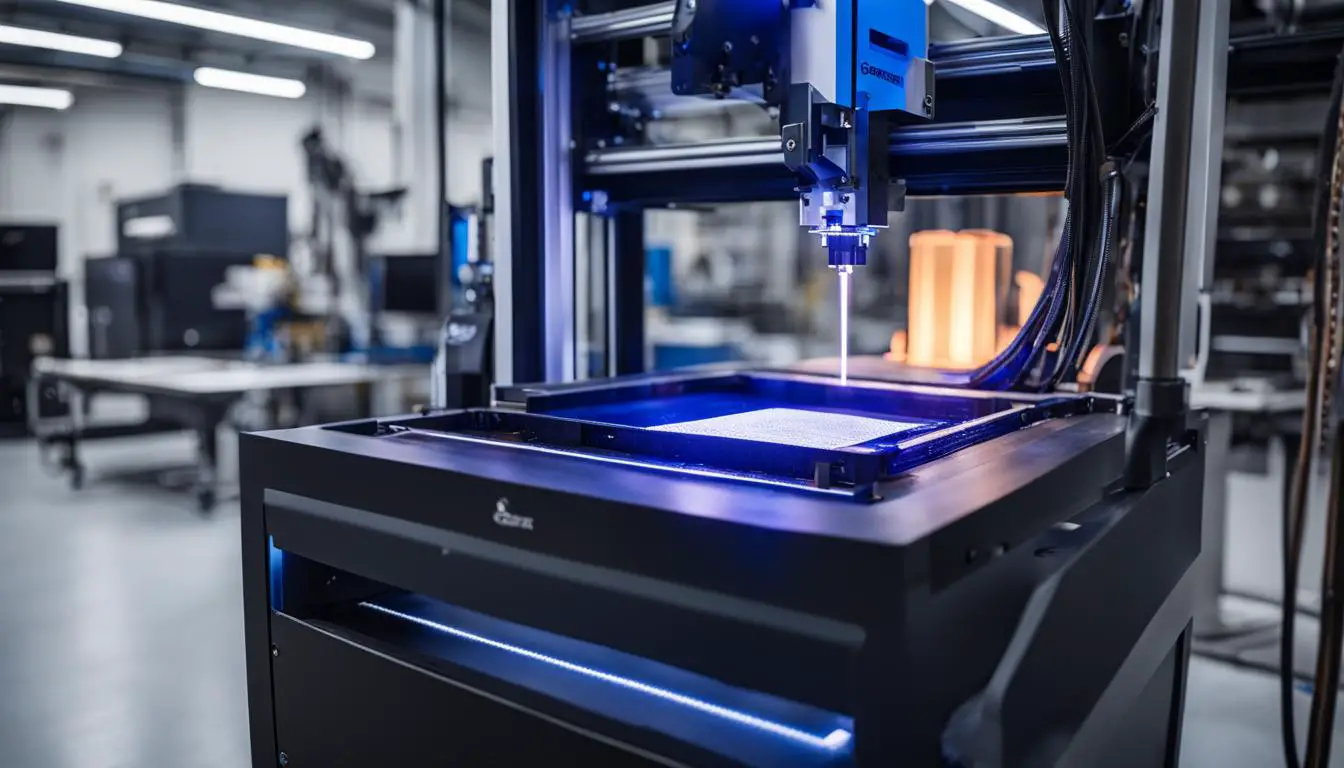

The Desktop Metal Production System is a state-of-the-art 3D printing system designed for the mass production of high-resolution metal parts. Powered by proprietary Single Pass Jetting (SPJ) technology, this system offers unmatched speed, precision, and cost-efficiency, revolutionizing the metal parts production process.

With its Single Pass Jetting technology, the Desktop Metal Production System is 100 times faster than traditional laser-based additive manufacturing systems. It achieves this by utilizing a printhead that deposits a binding agent onto a powder bed in a single pass. This approach eliminates the need for multiple passes and laser-based melting, resulting in significantly reduced production times.

Furthermore, the Desktop Metal Production System provides a cost-effective solution for metal parts production. By eliminating the costly tooling requirements of traditional manufacturing methods like casting, it offers a more economical alternative. Manufacturers can now achieve high-resolution metal parts production at a fraction of the cost, making it a game-changer for industries that rely on metal components.

Key Features of the Desktop Metal Production System:

- Single Pass Jetting (SPJ) technology for unparalleled speed and precision

- Elimination of costly tooling requirements, reducing production costs

- Ability to produce high-resolution metal parts on a large scale

- Support for a wide range of metals, including stainless steel, tool steels, and superalloys

- Simplified workflow with user-friendly software and intuitive interface

The Desktop Metal Production System empowers manufacturers to produce high-quality metal parts with efficiency and affordability. Its innovative technology and cost-saving advantages make it a game-changer in the field of metal parts production.

Desktop Metal’s Advantages and Innovations

Desktop Metal’s metal 3D printing systems offer numerous advantages and innovations that set them apart from traditional technologies. With their revolutionary Bound Metal Deposition (BMD) process, these systems provide a safer and more simplified metal 3D printing experience.

The BMD process eliminates the need for hazardous materials commonly used in other metal 3D printing methods, making it a more environmentally friendly option. The absence of lasers and cutting tools also enhances the safety of the printing process, reducing potential risks for operators.

In addition to its safety benefits, Desktop Metal’s systems offer exceptional versatility. They can support a wide range of metals, allowing engineers and manufacturers to choose the ideal material for their specific application. The ability to swap print cartridges enables seamless material changes, enabling greater flexibility in design and production.

“Desktop Metal’s systems provide faster printing speeds, reduced post-processing requirements, and competitive pricing compared to existing technologies. They are designed to disrupt the market and democratize metal 3D printing, making it accessible to a wider range of industries and professionals.” – Industry expert

Speed and Price Advantages

One of the key advantages of Desktop Metal’s systems is their speed. With the DM Production System utilizing Single Pass Jetting (SPJ) technology, it can achieve printing speeds 100 times faster than traditional laser-based additive manufacturing systems. This significant increase in speed enables manufacturers to meet demanding production timelines and improve overall productivity.

Alongside their speed, Desktop Metal’s systems provide cost advantages. By reducing the cost-per-part compared to laser-based systems, these metal 3D printers offer a competitive alternative to traditional manufacturing methods such as casting. These cost benefits open up new opportunities for businesses to explore metal parts production and optimize their production processes.

| Advantage | Description |

|---|---|

| Improved Safety | The use of Bound Metal Deposition eliminates hazardous materials and enhances operator safety. |

| Versatility | The ability to support various metals and easily swap print cartridges allows for greater design flexibility. |

| Faster Printing Speeds | The DM Production System’s Single Pass Jetting technology enables printing at 100 times the speed of laser-based systems. |

| Cost Savings | Reduced cost-per-part makes Desktop Metal’s systems a cost-effective alternative to traditional manufacturing methods. |

Desktop Metal’s innovative approach to metal 3D printing brings numerous advantages and transformations to the manufacturing industry. With their focus on safety, versatility, speed, and cost-effectiveness, these systems are poised to revolutionize production processes and empower businesses to create complex metal parts with efficiency and affordability.

The Challenges and Potential of Metal 3D Printing

Metal 3D printing has opened up new possibilities in manufacturing, but it also comes with its fair share of challenges and limitations. Understanding these obstacles is crucial for harnessing the full potential of this transformative technology.

Challenges of Metal 3D Printing

One of the major challenges in metal 3D printing is the high temperatures required for processing metals. Unlike traditional 3D printing materials, metal alloys have high melting points, making the printing process more complex and demanding. This necessitates specialized equipment and controlled environments to ensure successful printing.

Another challenge lies in the post-processing of metal 3D printed parts. The intricate geometries and internal structures created through metal additive manufacturing often require additional finishing processes like heat treatment, machining, or polishing to achieve the desired surface quality and dimensional accuracy.

Potential of Metal 3D Printing

Despite these challenges, metal 3D printing holds immense potential for transforming manufacturing processes. The ability to create complex shapes and internal cavities that were previously impossible with traditional manufacturing methods opens up new design possibilities. This enables engineers and designers to optimize part performance, reduce weight, and improve functionality.

Furthermore, the potential of metal 3D printing extends beyond just prototyping. The technology is now capable of producing end-use parts with high strength and durability, making it viable for a wide range of applications across industries such as aerospace, automotive, and healthcare.

Table: Comparing Challenges and Potential of Metal 3D Printing

| Challenges | Potential |

|---|---|

| High temperatures | Complex geometries |

| Post-processing requirements | Design freedom |

| Specialized equipment | End-use part production |

Metal 3D printing has the potential to revolutionize manufacturing by enabling the production of highly customized and lightweight parts with intricate designs. However, overcoming the challenges associated with this technology is vital for its widespread adoption and realization of its full potential.”

With ongoing advancements in materials, equipment, and process optimization, the limitations of metal 3D printing are continually being addressed. As research and development in this field progress, we can expect even greater breakthroughs, making metal additive manufacturing a key driver in transforming the manufacturing landscape.

Conclusion

Desktop Metal’s affordable and innovative metal 3D printing systems have the potential to revolutionize production processes. With the DM Studio System and DM Production System, you can now access safe, precise, and cost-effective solutions for both prototyping and mass production. These systems eliminate the need for expensive industrial facilities, making metal 3D printing more affordable than ever.

Whether you are a manufacturer or an engineer, these systems offer you the versatility and speed you need to transform your production processes. The DM Studio System, designed for rapid prototyping, allows you to create complex metal parts easily and efficiently. Meanwhile, the DM Production System, the fastest 3D printing system for mass production, reduces the cost-per-part and challenges traditional manufacturing techniques like casting.

By embracing Desktop Metal’s technology, you can unlock new possibilities in metal parts manufacturing. With the elimination of costly facilities, the versatility of prototyping, and the speed and price advantages, you have the tools to transform your production processes. Embrace the power of affordable metal 3D printing and witness the positive impact it can have on your designs, engineering, and manufacturing capabilities.

FAQ

Are the Desktop Metal 3D printers suitable for both prototyping and mass production?

Yes, the Desktop Metal Studio System and Production System are designed to offer affordable, safe, and precise metal 3D printing solutions for both prototyping and mass production purposes.

What is the difference between the Desktop Metal Studio System and Production System?

The Desktop Metal Studio System is specifically designed for office-friendly metal 3D printing and rapid prototyping, while the Desktop Metal Production System is meant for high-resolution metal parts mass production.

What technology does the Desktop Metal Studio System use?

The Desktop Metal Studio System uses Bound Metal Deposition (BMD) technology to create complex metal 3D printed parts with accurate geometries.

How does the Desktop Metal Production System achieve fast printing speeds?

The Desktop Metal Production System utilizes proprietary Single Pass Jetting (SPJ) technology, which is 100 times faster than laser-based additive manufacturing systems.

What advantages does Desktop Metal’s metal 3D printing systems offer?

Desktop Metal’s systems eliminate the need for hazardous materials, simplify the printing process, support a wide variety of metals, and provide faster printing speeds, reduced post-processing requirements, and competitive pricing compared to existing technologies.

What are the challenges of metal 3D printing?

Metal 3D printing has faced challenges due to the high temperatures required for processing metals and the complexity of metal processing. Traditional methods are slow, expensive, and confined to specialized companies with large budgets.

What is the potential of metal 3D printing?

Metal 3D printing has the potential to offer greater design freedom, the ability to create complex shapes and internal cavities, and redefine mass production economics.

Source Links

- https://www.desktopmetal.com/press/desktop-metal-is-set-to-change-how-metal-is-manufactured-with-the-fasted-metal-3d-printing-system-in-the-world

- https://www.forbes.com/sites/alexknapp/2017/04/25/this-startup-aims-to-revolutionize-metal-3d-printing-for-manufacturers/?sh=73411cc01e04

- https://www.technologyreview.com/2017/04/25/4855/the-3-d-printer-that-could-finally-change-manufacturing/