Experts Discuss: The Future Of 3D Printed Car

Originally posted on November 29, 2023 @ 7:45 pm

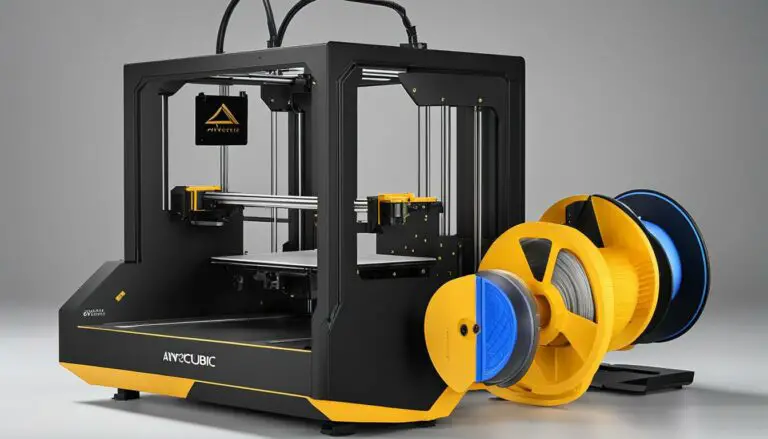

This piece takes a deep dive into the fascinating realm of 3D printed vehicles and examines the potential of this groundbreaking technology for the future of car manufacturing. The automotive industry utilizing 3D printing has been constantly advancing, transforming the traditional methods of car production and paving the way for endless possibilities in innovation. Join us as we delve into this captivating subject and uncover the endless potential of 3D printed cars.

Key Takeaways:

- 3D printing is revolutionizing the automotive industry, offering numerous benefits for car manufacturing.

- Design flexibility, reduced lead times, and cost-effectiveness are some of the advantages of 3D printed cars.

- By utilizing 3D printing technology, manufacturers can streamline the supply chain and reduce reliance on external suppliers.

- 3D printing enables rapid prototyping, allowing for quick iterations and design refinements in the automotive industry.

- 3D printing also plays a crucial role in automotive maintenance and repair operations, enabling the production of on-demand replacement parts.

Benefits of 3D Printed Cars

When it comes to the automotive industry, 3D printed cars offer a range of benefits that are revolutionizing car manufacturing. One of the key advantages of 3D printed car technology is the design flexibility it provides. Manufacturers can quickly produce prototypes, allowing for quicker design iterations and a faster time-to-market. This enables them to experiment with different designs and make improvements based on real-world testing.

Another advantage is the ability to create complex geometries that would be difficult or impossible to produce with traditional manufacturing methods. 3D printing allows for intricate detailing and precise customization, resulting in unique and personalized vehicles. Whether it’s a custom interior component or a specialized exterior feature, 3D printing opens up new possibilities for car design.

Furthermore, 3D printed cars can contribute to lightweighting efforts in the automotive industry. By using lightweight materials and optimizing designs for maximum strength and minimum weight, 3D printing enables the production of lighter vehicles. This not only improves fuel efficiency and reduces emissions but also meets regulatory requirements for sustainability.

| Benefits of 3D Printed Cars | Advantages |

|---|---|

| Design Flexibility | Quicker design iterations and faster time-to-market |

| Complex Geometries | Intricate detailing and precise customization |

| Lightweighting | Improved fuel efficiency, reduced emissions, and meeting sustainability regulations |

3D printed cars offer design flexibility, complex geometries, and opportunities for lightweighting, making them a game-changer in the automotive industry. With faster prototyping, more personalized designs, and improved sustainability, 3D printed cars are shaping the future of car manufacturing.

3D Printing and the Automotive Industry Supply Chain

The disruption to supply chains caused by the pandemic has prompted a reevaluation of manufacturing methods in the automotive industry. Companies are now exploring the potential of 3D printing for distributed and local manufacturing. By utilizing 3D printing technology, manufacturers can reduce their reliance on external suppliers and produce parts in-house, thereby streamlining the supply chain.

One of the key advantages of 3D printing in the automotive industry is the reduction in waste production. Traditional manufacturing processes often lead to significant amounts of material waste, whereas 3D printing allows for precise and efficient use of materials, minimizing waste. This not only improves the sustainability profile of the automotive industry but also helps reduce costs associated with waste disposal.

Recent developments in 3D printed car manufacturing have focused on scalability, higher throughput printing systems, enhanced reliability, and the integration of actionable data. These advancements enable manufacturers to increase production capabilities while maintaining high-quality standards. Additionally, the integration of data analytics and automation within the 3D printing process allows for improved process control and optimization.

Benefits of 3D Printing in Automotive Supply Chain:

- Reduced reliance on external suppliers

- Streamlined supply chain

- Minimized waste production

- Improved sustainability

- Scalability and higher throughput

- Enhanced reliability

- Integration of actionable data

With the ongoing advancements in 3D printing technology and its potential to revolutionize car manufacturing, it is clear that this innovative approach to production will play a significant role in shaping the future of the automotive industry.

| Impact of 3D Printing on the Automotive Industry Supply Chain | Benefits |

|---|---|

| Reduced reliance on external suppliers | Minimizes dependency on external suppliers, leading to greater control over the supply chain and reduced risks associated with sourcing parts. |

| Streamlined supply chain | By producing parts in-house, manufacturers can eliminate delays caused by external suppliers and reduce lead times. |

| Minimized waste production | 3D printing allows for precise use of materials, reducing waste and contributing to the sustainability of the automotive industry. |

| Improved sustainability | With reduced waste production and optimized material usage, 3D printing aligns with the growing emphasis on sustainability in the automotive industry. |

| Scalability and higher throughput | Advancements in 3D printing technology have enabled manufacturers to increase production capabilities without compromising quality. |

| Enhanced reliability | The latest developments in 3D printed car manufacturing focus on improving the reliability and consistency of printed parts, ensuring they meet the required standards. |

| Integration of actionable data | By incorporating data analytics and automation, manufacturers can optimize the 3D printing process for improved efficiency and cost-effectiveness. |

3D Printing in Automotive Prototyping

When it comes to automotive prototyping, 3D printing has become an invaluable tool for manufacturers. Its ability to rapidly produce parts allows for quick iterations and design refinements, saving both time and money. With 3D printing technology, manufacturers can easily create prototypes without the need for expensive molds or tooling, making it a cost-effective solution.

One of the key advantages of 3D printing in automotive prototyping is the ability to create complex geometries that would be challenging or impossible with traditional manufacturing methods. This opens up new possibilities for design innovation and optimization. Manufacturers can test and refine these complex geometries before committing to mass production, ensuring that the final product meets the required specifications.

Additionally, 3D printing enables customization in the automotive industry. Specific models or applications often require tailored components, and with 3D printing, manufacturers can easily produce these customized parts. This not only improves the fit and function of the components but also enhances personalization and customer satisfaction.

The Benefits of 3D Printing in Automotive Prototyping:

- Quick iterations and design refinements

- Cost-effectiveness by eliminating expensive molds and tooling

- Ability to create complex geometries for design optimization

- Customization for specific models or applications

Overall, 3D printing has revolutionized the automotive prototyping process, offering numerous benefits to manufacturers. Its speed, cost-effectiveness, and design flexibility make it an invaluable tool for the automotive industry. As technology continues to advance, we can expect even more advancements in 3D printing that will further enhance the prototyping process.

| Benefits of 3D Printing in Automotive Prototyping | Examples |

|---|---|

| Quick iterations and design refinements | Iterating on a car’s aerodynamic design to reduce drag |

| Cost-effectiveness by eliminating expensive molds and tooling | Producing a prototype of a complex engine component without the need for costly tooling |

| Ability to create complex geometries for design optimization | Designing a lightweight and structurally optimized suspension component |

| Customization for specific models or applications | Producing a tailored dashboard display for a specific car model |

3D Printing in Automotive Supply Chain Management

3D printing technology has revolutionized various industries, and the automotive sector is no exception. One area where 3D printing is making a significant impact is supply chain management. By utilizing 3D printing in the automotive supply chain, manufacturers can optimize operations, reduce costs, and enhance overall efficiency.

One of the key benefits of 3D printing in the automotive supply chain is the ability to produce parts locally. This reduces the need for extensive shipping and transportation, resulting in reduced lead times and costs. With 3D printing, manufacturers can produce parts on-demand, eliminating the need for large inventories and minimizing the risk of excess stock or shortages.

Moreover, 3D printing enables the creation of complex geometries and customizations that would be challenging or costly to achieve with traditional manufacturing methods. This flexibility allows manufacturers to optimize part designs for specific applications, improving overall performance and reducing waste.

Furthermore, the latest developments in 3D printed car manufacturing have focused on advancements in materials, manufacturing processes, and software integration. These advancements have contributed to improved logistics efficiency, enabling seamless integration of 3D printing into the automotive supply chain.

Advantages of 3D Printing in Automotive Supply Chain Management

Let’s take a closer look at the advantages that 3D printing brings to automotive supply chain management:

- Reduced shipping costs and lead times: By producing parts locally, manufacturers can eliminate the need for extensive shipping and transportation, resulting in faster delivery times and reduced costs.

- On-demand production: 3D printing allows manufacturers to produce parts as needed, eliminating the need for large inventories and reducing the risk of excess stock or shortages.

- Flexibility and customization: With 3D printing, manufacturers can easily create complex geometries and customize parts according to specific applications, improving overall performance and reducing waste.

- Integration and efficiency: The latest developments in 3D printed car manufacturing have enabled seamless integration of 3D printing into the automotive supply chain, improving overall logistics efficiency.

With these advantages, 3D printing is transforming the way automotive manufacturers manage their supply chains, offering cost savings, improved efficiency, and enhanced flexibility.

| Advantages of 3D Printing in Automotive Supply Chain Management |

|---|

| Reduced shipping costs and lead times |

| On-demand production |

| Flexibility and customization |

| Integration and efficiency |

3D Printing for Automotive Maintenance and Repair

When it comes to automotive maintenance and repair operations, 3D printing technology offers several advantages. With the ability to produce replacement parts on-demand, 3D printing reduces the need for large inventories and long lead times. This means that you can get the parts you need quickly, reducing downtime and improving efficiency.

Not only does 3D printing enable the rapid production of replacement parts, but it also allows for the reproduction of legacy parts. This is particularly useful for older vehicles that may no longer have readily available components. Instead of costly upgrades or replacements, 3D printing can reproduce these parts, keeping the vehicles in service for longer.

In addition to replacement parts, 3D printing can also be used to produce tooling and fixtures for maintenance and repair operations. By creating customized tools with 3D printers, technicians can improve the accuracy and efficiency of their work. This can lead to time and cost savings, making 3D printing a valuable tool in automotive maintenance and repair.

Benefits of 3D Printing in Automotive Maintenance and Repair:

- On-demand production of replacement parts: Reduce the need for large inventories and long lead times by printing parts as needed.

- Reproduction of legacy parts: Keep older vehicles in service without expensive upgrades or replacements.

- Customized tooling and fixtures: Improve accuracy and efficiency in maintenance and repair operations.

“With 3D printing technology, automotive maintenance and repair operations can benefit from reduced lead times, cost savings, and improved efficiency.” – [Expert Name], Industry Analyst

| Benefits | 3D Printing for Automotive Maintenance and Repair |

|---|---|

| On-demand production of replacement parts | Reduce the need for large inventories and long lead times by printing parts as needed. |

| Reproduction of legacy parts | Keep older vehicles in service without expensive upgrades or replacements. |

| Customized tooling and fixtures | Improve accuracy and efficiency in maintenance and repair operations. |

Lightweighting in the Automotive Industry with 3D Printing

The automotive industry has been increasingly focused on lightweighting in recent years. As fuel efficiency and environmental sustainability become more significant factors in car manufacturing, reducing vehicle weight has become a top priority. And 3D printing technology is playing a crucial role in achieving this goal.

By leveraging the design freedom offered by 3D printing, manufacturers can optimize parts to maximize strength while minimizing weight. This is particularly beneficial in the production of automotive components, where lightweight materials like carbon fiber-reinforced polymers can be used to create sturdy yet lightweight structures. The lighter weight of 3D printed car parts leads to improved fuel efficiency and reduced emissions, aligning with the industry’s sustainability objectives.

Additionally, 3D printing allows for the integration of functions, enabling the consolidation of multiple parts into a single component. This consolidation not only reduces weight but also simplifies assembly processes and reduces the number of potential failure points. With 3D printing, manufacturers can produce complex geometries and intricate structures that were previously impossible with traditional manufacturing methods, further contributing to lightweighting efforts in the automotive industry.

The revolutionary capabilities of 3D printing extend beyond lightweighting. This technology enables automotive manufacturers to produce custom parts on-demand, reducing waste and eliminating the need for large inventories. It also facilitates rapid prototyping and iteration, allowing for quicker design improvements and optimizing performance. As the 3D printing industry continues to advance, with advancements in materials and printing processes, the automotive industry can expect even greater innovations and transformative changes in car manufacturing.

Conclusion

The future of 3D printing in the automotive industry is bright. With advancements in materials, manufacturing processes, and software integration, 3D printing is set to revolutionize the way cars are produced. The benefits of 3D printed cars, such as design flexibility, reduced lead times, and lightweighting, make them an attractive option for manufacturers.

As the world shifts towards sustainability, 3D printing’s reduced waste production and use of lightweight materials align with these goals. The automotive industry can leverage 3D printing to optimize supply chain management, reduce shipping costs, and improve overall logistics efficiency.

With the ability to produce parts on-demand, 3D printing also plays a significant role in automotive maintenance and repair operations. From replacement parts to tooling and fixtures, 3D printing technology brings cost savings and efficiency to these processes.

The continued development and adoption of 3D printing technology will shape the future of car production. Embracing this revolution will allow automotive manufacturers to stay ahead of the competition and meet the demands of a rapidly evolving industry.

FAQ

What is the annual 3D Printing Industry Executive Survey?

The annual 3D Printing Industry Executive Survey collects insights from analysts, academics, CEOs, and CTOs, leading industrial additive manufacturing enterprises, and community advocates.

How could China’s reopening impact the 3D printing world?

China’s reopening in 2023 is predicted to boost GDP, which could have an impact on the 3D printing industry.

How has the pandemic affected the use of 3D printing for manufacturing?

The disruption to supply chains caused by the pandemic has led to a reappraisal of 3D printing for distributed and local manufacturing.

Is consolidation happening in the 3D printing industry?

Yes, consolidation in the 3D printing industry is underway or incoming.

What can we expect in terms of installations of additive manufacturing systems in 2023?

2023 is set to be a year of record installations of additive manufacturing systems.

What are the benefits of 3D printed cars?

3D printed cars offer several benefits, including design flexibility, reduced lead times, and cost-effectiveness. They also allow for quick production of prototypes and customization to specific models or applications.

How does 3D printing impact the supply chain in the automotive industry?

3D printing can help streamline the supply chain by reducing reliance on external suppliers and producing parts in-house. It also produces less waste, improving sustainability.

How can 3D printing benefit automotive prototyping?

3D printing enables the rapid production of parts, allowing for quick iterations and design refinements. It is also cost-effective and allows for the creation of complex geometries.

How does 3D printing optimize supply chain management in the automotive industry?

By producing parts locally, manufacturers can reduce shipping costs and lead times. It also reduces the need for expensive tooling and helps improve sustainability.

What role does 3D printing play in automotive maintenance and repair?

3D printing can produce replacement parts on-demand, reducing the need for inventories and long lead times. It can also reproduce legacy parts and improve the efficiency and accuracy of maintenance and repair operations.

How does 3D printing contribute to lightweighting in the automotive industry?

3D printing enables the production of lightweight components by optimizing designs for maximum strength and minimum weight. This improves fuel efficiency, reduces emissions, and meets regulatory requirements.

What does the future hold for 3D printing in the automotive industry?

The future of 3D printing in the automotive industry is promising, with advancements in materials, manufacturing processes, and software integration. It offers numerous benefits and aligns with sustainability goals.

Source Links

- https://3dprintingindustry.com/news/what-is-the-future-of-3d-printing-80-additive-manufacturing-experts-forecast-3d-printing-trends-for-2023-220261/

- https://www.dynamism.com/learn/automotive/the-future-of-automotive-manufacturing-exploring-the-benefits-of-3d-printing-in-2023.html

- https://www.techbriefs.com/component/content/article/tb/stories/blog/45593