Get Better Results: K40 Laser Upgrades Part2-Buy Now!

Originally posted on February 2, 2024 @ 2:48 pm

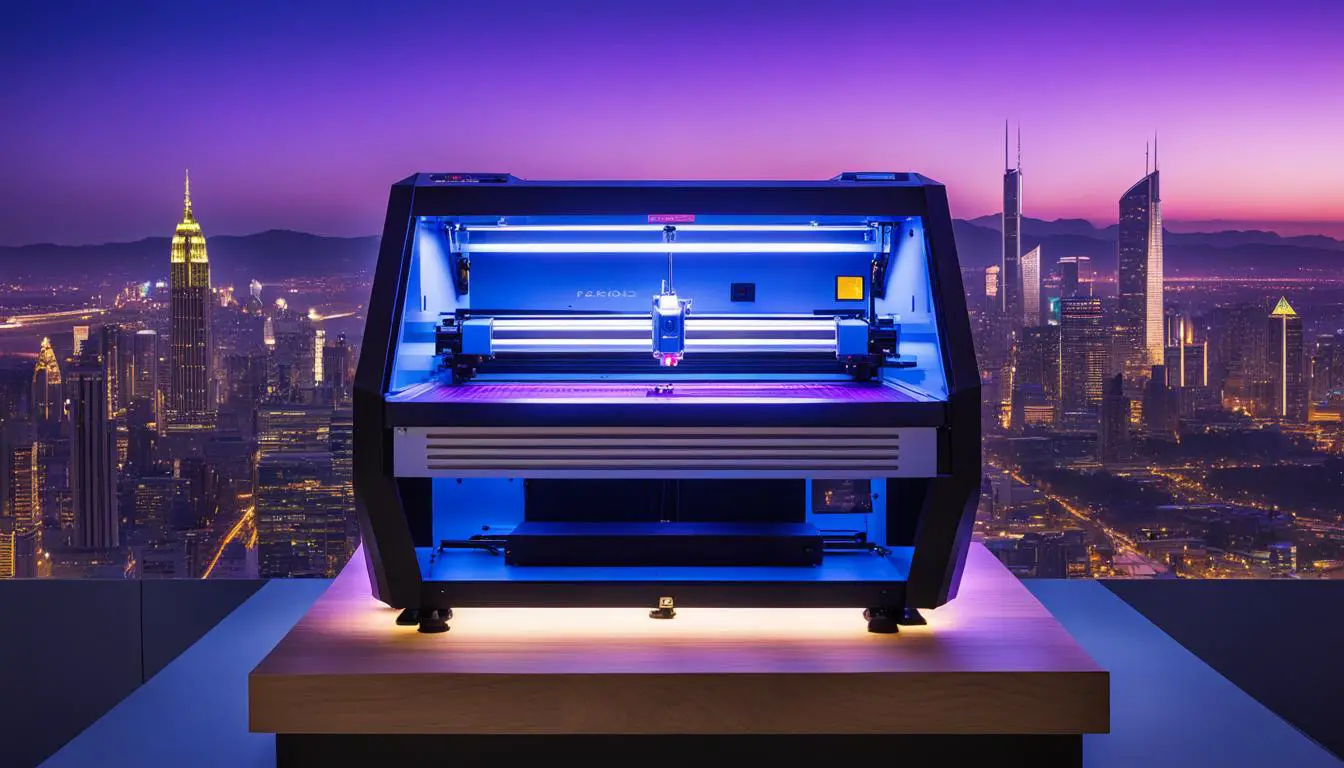

Welcome to the second part of our detailed guide on K40 laser improvements, where our aim is to boost the efficiency and functionality of your K40 laser cutter or engraver. In this piece, we’ll delve into several enhancements that can substantially improve the quality, accuracy, and flexibility of your device’s cutting and engraving operations. By adopting these enhancements, you’ll be able to attain outputs of professional caliber while maintaining affordability.

When it comes to the K40 laser machine, we understand the importance of maximizing its potential. That’s why we have curated a list of essential upgrades that address key areas such as the laser bed, smoke extraction system, air assist, controller board, and software. These upgrades, when combined, can significantly enhance your machine’s performance and take your projects to the next level.

If you’re ready to take control of your K40 laser machine’s capabilities, now is the perfect time to explore our K40 Laser Upgrades Part2. With our high-quality upgrade options and expert guidance, you can unlock the full potential of your K40 laser cutter or engraver. Don’t settle for average results when you can achieve greatness with our K40 laser upgrades.

Key Takeaways:

- Upgrade your K40 laser machine to achieve better cutting and engraving results.

- Enhance the laser bed for a larger working area and improved movement.

- Improve the smoke extraction system for better ventilation and reduced smoke accumulation.

- Enhance the air assist system for improved cutting efficiency and reduced charring.

- Monitor cooling water and temperature for optimal laser performance.

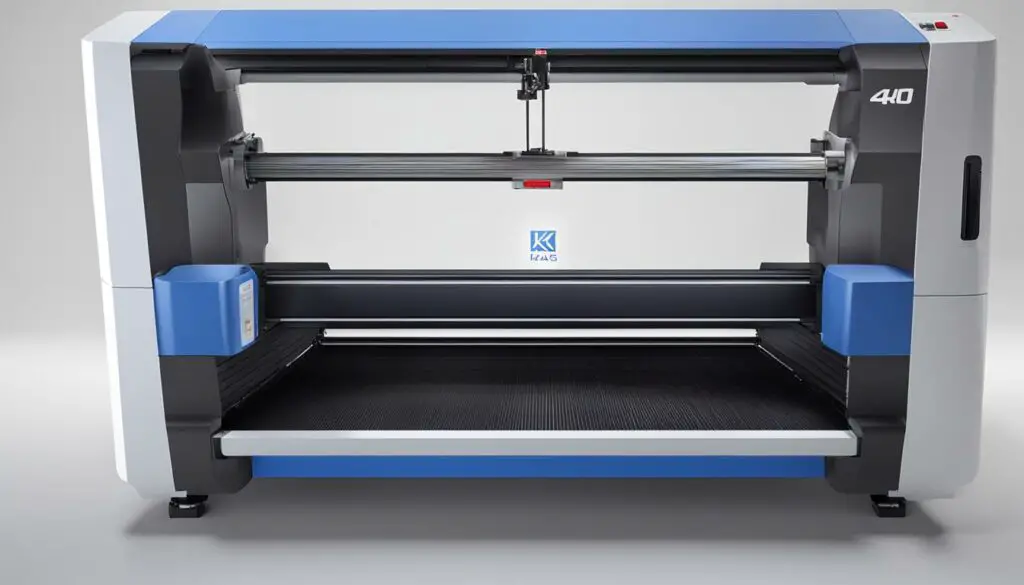

Upgrading the Laser Bed

The original laser bed that comes with the K40 machine is often too small, limiting the working area. To overcome this limitation, upgrading the laser bed to a larger size is essential. With a larger laser bed, users can enjoy a greater range of movement for the gantry, allowing for more versatile cutting and engraving options.

One recommended option for upgrading the laser bed is to use a perforated steel plate with 8mm holes. This type of plate provides a sturdy surface for materials while allowing for efficient airflow. Mounting the plate on threaded rods with adjustable height enables users to customize the bed’s positioning based on their specific needs.

To prevent staining or damage to the material being worked on, neodymium magnets can be used to raise the material slightly above the laser bed’s surface. These magnets provide a secure grip without obstructing the laser beam.

Additionally, using plywood gauges around the perimeter of the laser bed can help ensure materials are aligned properly and securely during the cutting or engraving process.

Another effective upgrade is the installation of an in-line fan box with an extra fan. This additional fan helps increase extraction efficiency by providing stronger suction power, effectively removing smoke and fumes from the laser cutting area.

In addition to trimming the smoke outlet duct and adding an in-line fan box, it is imperative to seal any gaps in the extraction system. By sealing these gaps, you minimize leaks and maximize the overall performance of the smoke extraction system.

Benefits of Upgrading the Smoke Extraction System:

• Better ventilation for a healthier working environment

• Reduced smoke accumulation and fume exposure

• Enhanced safety measures by preventing potential hazards

• Improved efficiency in removing smoke and fumes from the laser cutting area

| Upgrade | Benefits |

|---|---|

| Trimming the smoke outlet duct | – Prevent potential hazards – Safer operating environment |

| Adding an in-line fan box | – Increased extraction efficiency – Stronger suction power |

| Sealing gaps in the extraction system | – Minimized leaks – Improved overall performance |

Enhancing the Air Assist

In order to enhance the cutting and engraving process on your K40 laser, it is crucial to install an air assist system. This system plays a vital role in improving the overall efficiency and precision of your machine. Two popular options for upgrading the air assist are the CloudRay laser head and 3D printed air assists. Let’s explore these options in detail below:

CloudRay Laser Head

One excellent choice for enhancing the air assist on your K40 laser is the CloudRay laser head. This upgrade includes a new lens and mirror that are specifically designed to deliver improved performance. The CloudRay laser head provides precise and consistent air flow, ensuring optimal cooling and protection for your laser beam. By utilizing this upgrade, you can enhance the quality of your laser cuts and engravings, resulting in more professional and polished results.

3D Printed Air Assists

Another option for enhancing your K40 laser’s air assist is to utilize 3D printed air assists. These custom-designed accessories allow you to direct the air flow in line with the laser beam, ensuring optimal cooling and reducing the chances of charring or scorching the material. With 3D printed air assists, you can achieve improved cutting efficiency and better overall results.

Aside from upgrading the air assist, replacing the mirrors in your K40 laser with gold-on-silicon mirrors can also contribute to improved laser quality and power. These mirrors offer better reflectivity and durability, allowing for enhanced laser performance and a longer lifespan.

In Summary

Enhancing the air assist on your K40 laser is essential for achieving superior cutting and engraving results. By using a CloudRay laser head or 3D printed air assists, you can ensure optimal air flow and cooling, resulting in improved cutting efficiency and precision. Additionally, replacing the mirrors with gold-on-silicon mirrors can further enhance your laser’s performance. Upgrade your air assist system today and unlock the full potential of your K40 laser machine.

| Upgrades | Benefits |

|---|---|

| CloudRay laser head | Improved performance and precision |

| 3D printed air assists | Enhanced cutting efficiency |

| Gold-on-silicon mirrors | Better laser quality and power |

Monitoring Cooling Water and Temperature

Proper monitoring of the cooling water flow and temperature is crucial for the optimal performance of your K40 laser machine. Without adequate cooling, the laser tube can overheat, leading to reduced efficiency and potential damage.

To ensure accurate temperature readings, we recommend installing a dual thermometer that can measure the inlet and outlet water temperatures simultaneously. This allows you to keep a close eye on any temperature fluctuations that may affect the laser’s performance.

Additionally, incorporating a flow switch into your cooling system provides an extra layer of protection. The flow switch acts as an early warning system, instantly alerting you if the water flow stops. This prompt notification can prevent potential issues caused by a lack of water circulation.

Another critical aspect of maintaining the cooling water is using deionized water. Deionized water has been purified to remove impurities, minerals, and dissolved solids. By using deionized water, you minimize the risk of scale buildup and ensure the consistent performance of the cooling system.

**Note:** It’s important to keep the water temperature within the recommended range of 15-25°C. Extreme temperatures can negatively impact the laser’s functionality and lifespan. To regulate the temperature, you can consider adding accessories such as an aquarium heater to your cooling system.

Benefits of Monitoring Cooling Water and Temperature

Properly monitoring cooling water and temperature offers several advantages:

- Prevents overheating and potential damage to the laser tube

- Ensures consistent laser performance and cutting/engraving quality

- Provides early warning of water flow interruptions

- Minimizes the risk of scale buildup and clogging

- Extends the lifespan of your K40 laser machine

Summary

Monitoring the cooling water flow and temperature in your K40 laser machine is essential for maintaining optimal performance and longevity. By investing in a dual thermometer, flow switch, and using deionized water, you can ensure that your laser operates at its best. Take the necessary steps to monitor and regulate the cooling system, and you’ll enjoy reliable and efficient laser cutting and engraving for years to come.

Upgrading the Controller Board

When it comes to upgrading your K40 machine, one crucial component that should not be overlooked is the controller board. The controller board plays a vital role in providing precise control and power modulation for your laser, ultimately impacting the quality of your cutting and engraving results. By upgrading the controller board, you can unlock a whole new level of performance and functionality.

We highly recommend considering the Smoothie board as a replacement for your K40’s controller board. This upgraded board offers improved performance and advanced features that can take your laser experience to the next level. With the Smoothie board, you gain the ability to use PWM (Pulse Width Modulation) for greyscale engraving, allowing you to achieve stunning levels of detail and shading in your designs.

What makes the Smoothie board particularly advantageous for K40 machines is its compatibility with CO2 laser power control. This means that you can easily regulate the power output of your laser, providing greater precision and control over the cutting and engraving process.

Moreover, the Smoothie board seamlessly integrates with LightBurn software, a powerful and intuitive laser control program. This integration opens up a world of possibilities, giving you access to advanced features and tools that can further enhance your laser projects. With LightBurn, you can optimize your workflow, import various file formats, and enjoy a user-friendly interface for effortless laser control.

By upgrading the controller board of your K40 machine with the Smoothie board and integrating it with LightBurn software, you can expect better control, improved power modulation, and enhanced functionality. These upgrades translate to more precise laser current settings, resulting in sharper cuts, finer engraving details, and overall superior cutting and engraving results.

“Upgrading the controller board of your K40 machine with the Smoothie board and integrating it with LightBurn software can bring your laser projects to a whole new level of precision and control.”

Investing in a controller board upgrade is a smart decision for anyone looking to maximize the potential of their K40 machine. With the Smoothie board and LightBurn software, you can unlock a world of possibilities and achieve professional-grade laser capabilities, all from the comfort of your own workshop.

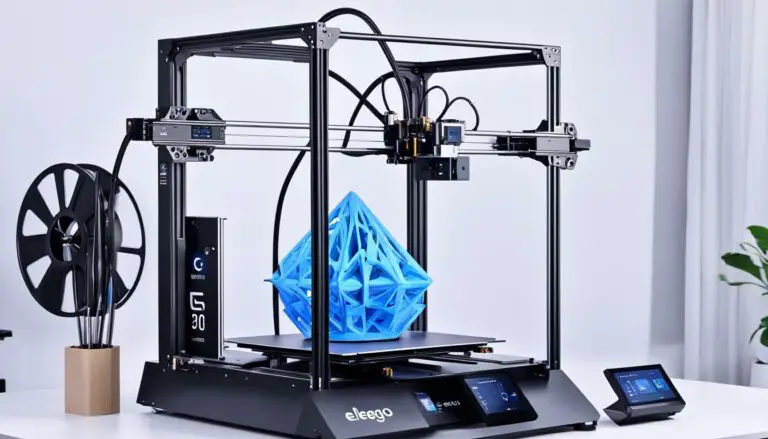

A DIY Xtreeem K40 Rotary Attachment

Expanding the capabilities of your K40 laser machine is possible with a DIY rotary attachment. By building and installing this attachment, you can enable rotary engraving on your K40, opening up new creative possibilities. Our mechanical build process and design improvements ensure smooth operation and optimal performance.

When constructing the rotary attachment, we recommend using high-quality materials and precise measurements to ensure a sturdy and reliable build. Attention to detail during the assembly process is crucial for achieving accurate and consistent results. The addition of a rotary attachment allows you to engrave cylindrical or curved objects with ease, such as glassware, bottles, and tumblers.

Before finalizing your rotary attachment, thorough testing is necessary to verify its functionality and performance. This includes evaluating the rotation mechanism, centering the object to be engraved, and ensuring proper alignment with the laser beam. Conducting testing procedures allows you to make any necessary adjustments and fine-tune the attachment for optimal engraving results.

The DIY rotary attachment for the K40 laser machine provides added versatility and expands your creative possibilities. With its ability to engrave curved surfaces, you can personalize a wide range of objects and create stunning, intricate designs. Elevate your laser engraving projects with the Xtreeem K40 rotary attachment.

Conclusion

Upgrading various components of the K40 laser machine can significantly enhance its performance and capabilities. By investing in upgrades such as the laser bed, smoke extraction system, air assist, controller board, and software, users can achieve superior cutting and engraving results, improved precision, and enhanced versatility.

With these upgrades, the K40 laser cutter can deliver professional-quality output that rivals high-end laser machines, all at a fraction of the cost. Whether you are a hobbyist, small business owner, or professional, upgrading your K40 laser machine is a wise investment that can unlock its full potential and take your projects to the next level.

Experience the power and capabilities of a fully upgraded K40 laser cutter. Elevate your performance and unleash your creativity with the enhanced features and functionalities of these upgrades. Get started today and see the remarkable difference in the performance and capabilities of your K40 laser engraver.

FAQ

What upgrades are necessary for the K40 laser cutter?

Upgrades to the laser bed, smoke extraction system, air assist, controller board, and software are necessary for optimal performance.

How can I upgrade the laser bed on my K40 machine?

One option is to use a larger perforated steel plate with adjustable height using threaded rods and neodymium magnets.

How can I improve the smoke extraction on my K40 machine?

Trimming the smoke outlet duct and adding an in-line fan box can enhance ventilation and extraction efficiency.

What are some options for enhancing the air assist on my K40 laser?

Consider using a CloudRay laser head, 3D printed air assists, and gold-on-silicon mirrors to improve the cutting and engraving process.

How can I monitor the cooling water flow and temperature for my K40 laser?

Installing a dual thermometer and a flow switch can provide accurate readings and alert users if the water flow stops.

What is a recommended upgrade for the controller board of the K40 machine?

The Smoothie board is a popular choice that offers improved control and power modulation, along with compatibility with CO2 laser power control and LightBurn software integration.

Can I add a rotary attachment to my K40 laser machine?

Yes, building a DIY rotary attachment is possible and expands the machine’s capabilities for rotary engraving cylindrical objects.

How can I improve the overall performance of my K40 laser cutter?

By upgrading various components and implementing the recommended modifications, you can achieve better cutting and engraving results, increased precision, and enhanced versatility.