The Future of MakerBot 3D Printer: A Discussion with Experts

Originally posted on December 15, 2023 @ 9:44 pm

The following piece takes a close look at the fascinating realm of MakerBot 3D printing, which has played a pivotal role in bringing this technology to a broader audience. As a top player in the field, MakerBot has been continuously pushing the boundaries of innovation. We will examine the evolution of MakerBot and hear from professionals in the industry who have closely followed its development.

Key Takeaways:

- MakerBot is revolutionizing 3D printing with its innovative technology and commitment to accessibility.

- 3D printing allows for the creation of complex objects, transforming industries such as healthcare, automotive, and more.

- MakerBot’s journey began in 2009 with a mission to make 3D printing available to everyone.

- The evolution of MakerBot’s technology has introduced user-friendly features and reliability.

- MakerBot has made significant contributions to education and professional users in the 3D printing space.

Understanding the Basics of 3D Printing

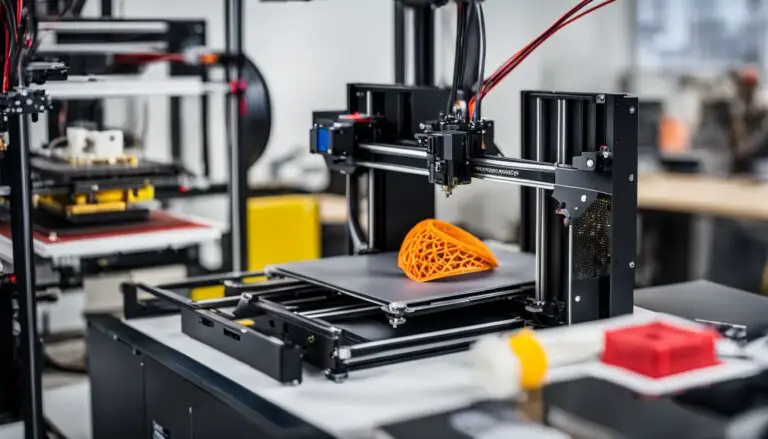

3D printing, also known as additive manufacturing, is a groundbreaking technology that has revolutionized the way objects are created. It involves the process of transforming digital designs into physical objects by building them layer by layer. This innovative method has gained popularity in various industries, including healthcare, automotive, and aerospace.

The key to 3D printing lies in the digital design file, which serves as the blueprint for the object being printed. These digital files can be created using computer-aided design (CAD) software or downloaded from online repositories. Once the design is finalized, it is sliced into thin layers, which are then sent to the 3D printer.

The 3D printer uses a range of materials, including plastics, metals, and even bio-inks, to build the object layer by layer. The printer deposits the material in precise locations based on the instructions from the digital design file. As each layer is added, the object takes shape until it is complete. This layer-by-layer construction allows for the creation of complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods.

The Advantages of 3D Printing

There are several advantages to using 3D printing compared to traditional manufacturing processes. One of the main benefits is the ability to create highly customized objects. With 3D printing, it is possible to design and produce unique items tailored to individual needs or specific requirements. This level of customization opens up new possibilities in industries such as healthcare, where personalized medical devices and implants can be created.

Another advantage of 3D printing is its ability to reduce waste. Traditional manufacturing processes often result in a significant amount of material being discarded as scrap. In contrast, 3D printing is an additive process, meaning that only the required amount of material is used to create the object. This not only reduces waste but also makes the process more cost-effective.

Additionally, 3D printing allows for rapid prototyping and iteration. Designers and engineers can quickly create physical prototypes of their ideas, test them, and make necessary modifications. This iterative process can significantly speed up product development cycles and lead to more innovative and refined designs.

The Future of 3D Printing

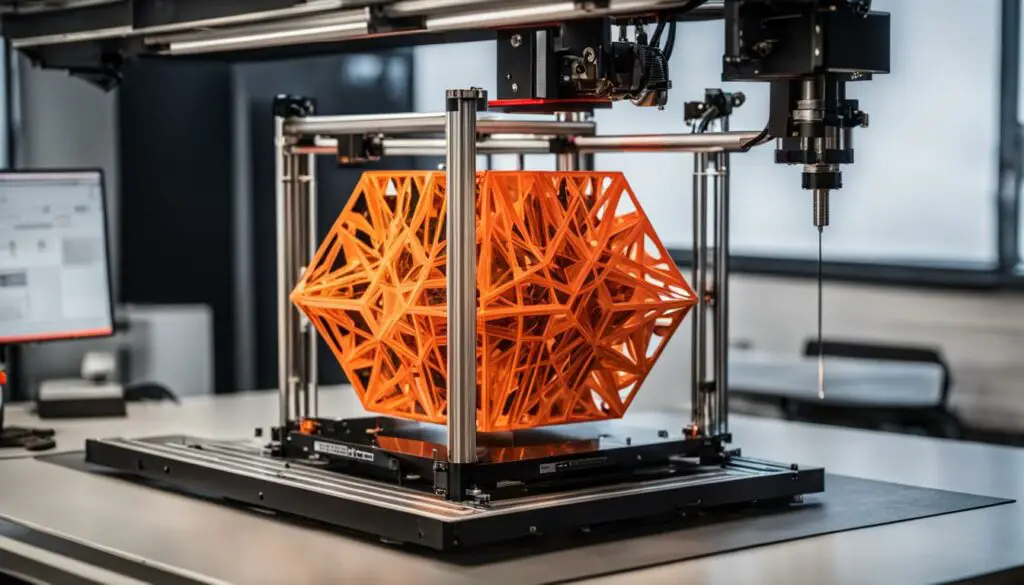

As 3D printing technology continues to advance, its applications are expected to expand further. Currently, 3D printing is predominantly used in prototyping and small-scale production. However, there is growing interest in using this technology for large-scale manufacturing as well.

Researchers are exploring new materials and techniques to enhance the capabilities of 3D printing. For example, advancements in bioprinting are paving the way for the creation of complex organs and tissues for medical purposes. Similarly, the development of printable electronics holds the potential for revolutionizing the production of electronic devices.

Furthermore, 3D printing is becoming more accessible to individuals and small businesses. The cost of 3D printers has decreased significantly in recent years, making them more affordable and widely available. This accessibility, coupled with the increasing availability of online resources and communities, is empowering a new generation of makers and innovators, fueling further growth and innovation in the field of 3D printing.

| Advantages of 3D Printing | Examples |

|---|---|

| Customization | Personalized medical devices |

| Waste reduction | Cost-effective material usage |

| Rapid prototyping | Accelerated product development cycles |

The Impact of 3D Printing on Industries

3D printing has revolutionized various industries, bringing significant advancements and opportunities. Let’s explore how this technology has made a profound impact in healthcare, automotive, supply chain management, and the maker community.

Healthcare

In the healthcare industry, 3D printing has transformed the way medical devices and prosthetics are designed and produced. Healthcare professionals can now create custom-fit implants and prosthetics tailored to individual patients, improving comfort and functionality. This technology has also been instrumental in surgical planning, allowing surgeons to practice complex procedures on accurate 3D models beforehand, resulting in better outcomes for patients.

Automotive

The automotive industry has embraced 3D printing for prototyping and production purposes. With the ability to rapidly create intricate parts and components, automakers can iterate designs quickly, reducing development time and costs. Additionally, 3D printing enables the production of lightweight and complex geometries that improve fuel efficiency and performance. This technology has also facilitated the customization of vehicles, allowing consumers to personalize their cars with unique designs and features.

Supply Chain

3D printing has disrupted traditional supply chain models by enabling on-demand manufacturing. Instead of relying on mass production and lengthy shipping times, manufacturers can now produce goods locally and in real-time. This not only reduces transportation costs and lead times but also minimizes inventory storage requirements. By leveraging 3D printing technology, companies can respond quickly to market demands and achieve greater flexibility in their supply chain operations.

Maker Community

The maker community has embraced 3D printing as a powerful tool for bringing ideas to life. With affordable desktop 3D printers becoming more accessible, individuals and small businesses can turn their concepts into physical objects without the need for large-scale manufacturing facilities. This democratization of manufacturing has unleashed creativity and innovation, enabling makers to prototype and produce custom products, artwork, and even functional prototypes for entrepreneurial ventures.

3D printing has made a significant impact across various industries, revolutionizing healthcare, automotive, and supply chain management. It has empowered individuals in the maker community, fostering innovation and creativity. As this technology continues to advance, we can expect further transformative changes and new possibilities in the years to come.

The Impact of MakerBot

“MakerBot’s open-source philosophy has revolutionized the world of 3D printing. It has empowered a new wave of makers and creators, allowing them to design and print their own objects with ease. This accessibility has opened up endless possibilities for innovation and customization.”

From hobbyists to professionals, people have embraced MakerBot’s printers for their reliability, ease of use, and affordability. The accessibility of MakerBot’s technology has not only democratized 3D printing but also supported the growth of small businesses and entrepreneurial endeavors. With MakerBot, anyone with a desktop 3D printer can become a manufacturer, designer, and entrepreneur.

The Future of MakerBot

As 3D printing technology continues to evolve, MakerBot remains at the forefront of innovation. Their commitment to accessibility, open-source, and collaboration positions them well for the future. MakerBot’s dedication to providing user-friendly features, comprehensive software ecosystems, and support for education and professional users further solidifies their role as a leader in the industry.

Looking ahead, MakerBot will continue to revolutionize the way we create, design, and manufacture objects. Their impact on the accessibility of 3D printing has already been profound, and the future holds even more exciting possibilities as this transformative technology becomes more integrated into our lives.

The Evolution of MakerBot’s Technology

MakerBot has continuously pushed the boundaries of 3D printing technology over the years. Their printers are known for their reliability and high-quality prints. With a focus on user-friendly features and a comprehensive software ecosystem, MakerBot has made 3D printing accessible to a wide range of users.

One of the standout features of MakerBot printers is their reliability. Whether you’re a professional user or a hobbyist, you can count on MakerBot to deliver consistent, precise prints every time. Their printers are built with top-notch components and undergo rigorous testing to ensure optimal performance.

To enhance user experience, MakerBot has introduced various user-friendly features. For example, their printers come with automated bed leveling, which eliminates the need for manual calibration and saves users valuable time. Additionally, MakerBot printers are equipped with filament detection, which automatically pauses the print job if the filament runs out, preventing wasted prints.

MakerBot’s commitment to user-friendly features doesn’t end with hardware. They also provide a comprehensive software ecosystem that supports users at every step of the 3D printing process. From intuitive design software to powerful slicing programs, MakerBot’s software suite empowers users to bring their ideas to life with ease.

The MakerBot Software Ecosystem

The MakerBot software ecosystem consists of several powerful tools that streamline the 3D printing workflow. One of the key components is MakerBot Print, a user-friendly software that allows users to prepare, slice, and send print files to their MakerBot printer. Users can easily import designs, position them on the build platform, and adjust print settings to achieve the desired results.

In addition to MakerBot Print, MakerBot provides Thingiverse, a popular online platform that hosts millions of 3D printable designs. Users can browse through a vast library of models, download them, and print them on their MakerBot printer. Thingiverse also serves as a community hub, allowing users to share their own designs and connect with fellow 3D printing enthusiasts.

Overall, MakerBot’s evolution in technology has not only made 3D printing more accessible but also more enjoyable for users. Their commitment to reliability, user-friendly features, and a robust software ecosystem has solidified their position as a leader in the 3D printing industry.

| Reliability | User-Friendly Features | Software Ecosystem |

|---|---|---|

| Consistent, precise prints | Automated bed leveling | MakerBot Print software |

| Top-notch components | Filament detection | Thingiverse platform |

| Rigorous testing | Community engagement |

MakerBot’s Contribution to 3D Printing

MakerBot has made significant contributions to the field of 3D printing, solidifying its position as a trusted and innovative brand. With a focus on accessibility, education, and professional users, MakerBot has paved the way for the widespread adoption of this transformative technology.

When it comes to 3D printing education, MakerBot stands at the forefront. Their printers have been embraced by educators worldwide, with over 10,000 schools incorporating MakerBot technology into their classrooms. By providing accessible and affordable 3D printing solutions, MakerBot has empowered students to explore their creativity and develop hands-on problem-solving skills.

Professional users also benefit greatly from MakerBot’s offerings. The reliability and high-quality prints produced by MakerBot printers make them invaluable tools for designers, engineers, and architects. By addressing the specific needs of professionals, MakerBot has created a niche market that prioritizes accuracy, precision, and efficiency in 3D printing.

Table: MakerBot’s Impact on 3D Printing Education and Professional Users

| Education | Professional Users |

|---|---|

|

|

“MakerBot’s commitment to accessibility and education has revolutionized the way students learn and innovate. Their printers have become an essential tool in classrooms, allowing students to bring their ideas to life and gain valuable real-world skills.” – Emily Thompson, Educator

Through their dedication to 3D printing education and professional users, MakerBot has shaped the landscape of the industry. Their commitment to innovation, reliability, and accessibility has made 3D printing more inclusive and attainable for all, whether in educational institutions or professional settings.

Conclusion

As we conclude our exploration of the future of MakerBot 3D printers and the exciting world of 3D printing technology, it’s clear that MakerBot is poised to play a significant role in shaping the future of this transformative technology. With their unwavering commitment to innovation, accessibility, and collaboration, MakerBot continues to push the boundaries of what 3D printing can achieve.

With a strong focus on producing reliable printers and delivering high-quality prints, MakerBot has earned the trust of educators and professionals alike. Their printers have found a home in over 10,000 schools worldwide, supporting 3D printing education and empowering students to unleash their creativity.

Looking ahead, the future of MakerBot is promising. As 3D printing becomes increasingly integrated into various industries, MakerBot’s commitment to accessibility and their comprehensive software ecosystem make them an ideal choice for individuals and businesses alike. Whether you’re an educator, a hobbyist, or a professional user, you can rely on MakerBot to provide the tools you need to bring your ideas to life.

In conclusion, MakerBot’s dedication to innovation and collaboration, combined with their user-friendly features and commitment to accessibility, place them at the forefront of the 3D printing revolution. With MakerBot, the future of 3D printing technology looks brighter than ever.

FAQ

What is 3D printing?

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from digital files.

How does 3D printing work?

The process involves designing a digital model, slicing it into layers, and using a 3D printer to print the object layer by layer.

What industries have been impacted by 3D printing?

3D printing has had a profound impact on industries such as healthcare and automotive, enabling customized medical implants, revolutionizing prototyping, and disrupting the supply chain.

What is MakerBot?

MakerBot is a company founded in 2009 with the mission to make 3D printing accessible to everyone by offering affordable desktop 3D printers.

What makes MakerBot printers stand out?

MakerBot printers are known for their reliability and high-quality prints. They also have user-friendly features like automated bed leveling and filament detection.

How has MakerBot contributed to the field of 3D printing?

MakerBot has made substantial contributions by providing comprehensive solutions for education, supporting professional users, and fostering a collaborative community.

What is the future of MakerBot?

With their commitment to innovation, accessibility, and collaboration, MakerBot is well-positioned to shape the future of 3D printing technology.