Upgrade Your Dental Lab with These Top 7 Dental 3D Printer Options

Originally posted on December 14, 2023 @ 7:16 pm

In the present piece, we will discuss the leading 7 dental 3D printers that are set to transform your dental laboratory and assist you in meeting the growing demand for dental products. These printers have the capability to produce precise and personalized dental prosthetics, making them a game-changing tool in the field.

Key Takeaways:

- Upgrade your dental lab with a dental 3D printer to enhance your workflow and patient care.

- Dental parts are 3D printed using specialized CAD software and converted into formats that dental 3D printers can understand.

- Stereolithography (SLA), Digital Light Processing (DLP), and Masked Stereolithography (mSLA) are three common technologies used in dental 3D printing.

- Nexa3D NXE 400Pro, Nexa3D XiP, Form 3B+, Stratasys J700 Dental, Roland DWX-51D, Whip Mix Asiga Max, and BEGO Varseo S are some of the best dental 3D printers available.

- Dental 3D printers offer benefits such as time savings, improved accuracy, and expanded treatment options.

How are dental parts 3D printed?

Dental parts are 3D printed using advanced technology that combines digital dentistry and CAD/CAM systems. This process revolutionizes traditional methods of creating dental prosthetics, offering improved accuracy and customization. Here’s a step-by-step breakdown of how dental parts are 3D printed:

- Digital Scanning: The process begins with a digital scan of the patient’s teeth or oral cavity. This scan captures detailed images that serve as the foundation for creating the 3D model.

- Digital Model Creation: The scanned data is then processed using specialized CAD software to create a precise 3D digital model of the dental part. This model serves as the blueprint for the 3D printing process.

- Conversion to Printable Format: The CAD software converts the digital model into a format that can be understood by a dental 3D printer. This conversion process involves using a 3D slicer to divide the 3D model into thin layers, ensuring the printer can accurately recreate each layer.

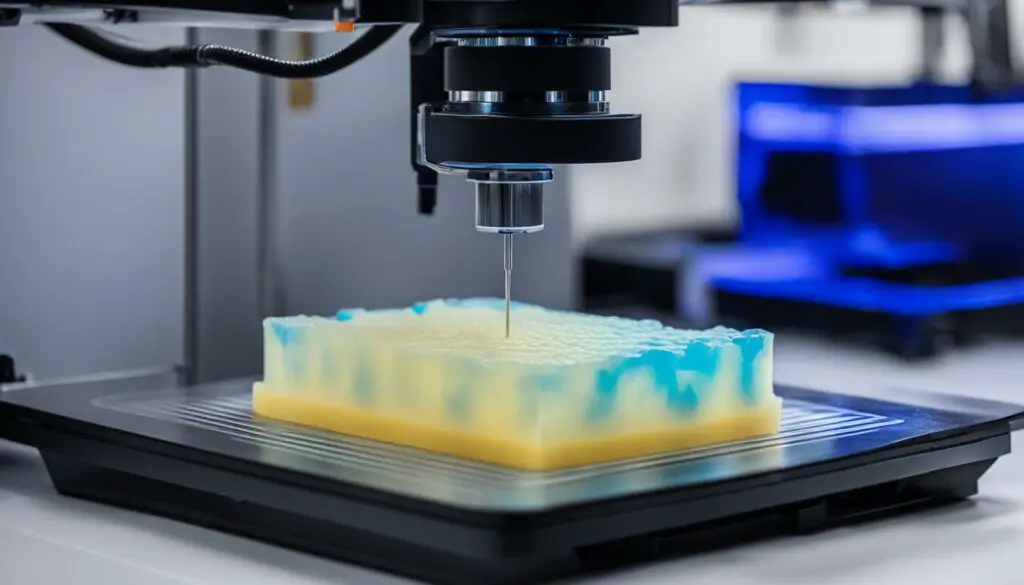

- Layer-by-Layer Printing: The dental 3D printer then builds the object layer by layer, following the instructions from the 3D slicer. Depending on the 3D printing technology used, each layer is cured or fused together to create a solid and durable dental part.

- Post-processing: Once the 3D printing is complete, the dental part may require post-processing to achieve the desired finish. This may involve removing support structures, polishing the surface, or applying additional treatments.

This advanced 3D printing technology for dental applications offers numerous benefits, such as increased efficiency, improved accuracy, and the ability to create highly customized dental prosthetics. With digital dentistry and CAD/CAM systems, dental labs and clinics can enhance their workflows and provide patients with precise and tailored dental solutions.

Stereolithography (SLA) Technology

Stereolithography (SLA) is a resin 3D printing technology that uses a laser to cure photosensitive materials layer by layer, creating solid parts. SLA is widely used in various industries, including the dental field, due to its ability to produce precise prototypes with watertight tolerances and smooth surfaces. This technology is particularly valuable in the creation of dental molds, guides, and trays.

SLA printers work by using a laser to solidify liquid resin, layer by layer, according to a 3D digital model. The laser selectively cures the resin, creating a solid part. The process allows for the production of highly detailed and accurate dental devices with intricate geometries. SLA technology is known for its ability to achieve smooth surface finishes, making it suitable for dental applications where aesthetics are important.

Stereolithography revolutionized the dental industry by enabling the creation of precise prototypes and functional parts with exceptional accuracy and detail. The technology’s ability to produce smooth surfaces and watertight tolerances has significantly improved the efficiency and quality of dental prosthetics.

One of the advantages of SLA technology is its wide range of available resin materials, including bio-compatible resins that are safe for dental applications. These resins offer high strength, durability, and resistance to wear, making them ideal for producing dental devices that can withstand the demanding oral environment.

| Advantages | Disadvantages | |

|---|---|---|

| Smooth surface finish | Highly accurate | Higher cost compared to other 3D printing technologies |

| Watertight tolerances | Wide range of resin materials | Post-processing may be required for some applications |

| Precise prototypes with intricate geometries | Ability to produce bio-compatible dental devices |

Overall, stereolithography (SLA) technology offers dental professionals the ability to create precise dental prototypes and functional parts with exceptional accuracy and detail. With its smooth surface finishes, watertight tolerances, and wide range of available resin materials, SLA has become a valuable tool in the dental industry.

Digital Light Processing (DLP) Technology

Digital Light Processing (DLP) is a cutting-edge 3D printing technology that offers high detail, fast printing speed, and a smooth surface finish. Unlike traditional SLA printers that use a laser to cure resin, DLP printers utilize a digital light projector or an LCD screen to expose the entire layer of liquid resin to light at once, resulting in faster printing speeds.

One of the key advantages of DLP technology is its ability to produce intricate and highly detailed parts. The digital light projector or LCD screen creates a precise pattern of light, allowing for the accurate curing of the resin. This level of detail is especially important in the dental industry, where precision is crucial for creating dental prosthetics and devices that fit perfectly.

Additionally, DLP technology offers faster print times compared to traditional SLA printers. Since the entire layer of resin is cured simultaneously, DLP printers can complete prints more quickly, speeding up the production process in dental labs and clinics. The fast printing speed of DLP technology also makes it an ideal choice for high-volume production.

| Advantages of DLP Technology | Limitations of DLP Technology |

|---|---|

|

|

Overall, DLP technology offers significant advantages in terms of speed, detail, and surface finish, making it a popular choice for dental applications. By leveraging the capabilities of DLP 3D printers, dental professionals can enhance their workflow and deliver high-quality dental prosthetics and devices to their patients.

Advantages of mSLA Technology

One of the key advantages of mSLA technology is its fast printing speed. With the use of an LED array light source, dental professionals can significantly reduce the time it takes to produce dental prosthetics and devices. This increased efficiency can help labs meet tight deadlines and deliver timely solutions to patients.

Moreover, mSLA technology excels at printing complex geometries with intricate details. The precise control provided by the LED array light source enables the creation of highly accurate and intricately designed dental parts. As a result, dental professionals can achieve superior fit and function, enhancing patient satisfaction.

In summary, masked stereolithography (mSLA) technology is revolutionizing the dental industry by offering faster printing speeds and the ability to produce complex geometries with exceptional precision. With its advanced LED array light source and optimized image quality, mSLA technology is paving the way for more efficient and versatile dental 3D printing solutions.

Best Dental 3D Printers

When it comes to dental 3D printers, there are several top-notch options available in the market. These printers offer advanced features, cutting-edge technology, and exceptional print quality that can elevate your dental lab to new heights. Here, we will explore some of the best dental 3D printers that you should consider for your practice.

One of the standout dental 3D printers is the Nexa3D NXE 400Pro. This industrial resin printer utilizes Nexa3D’s patented LSPc® technology, which ensures ultrafast speeds, exceptional accuracy, and a large build volume. With its high-resolution capabilities, the NXE 400Pro is ideal for producing intricate dental prosthetics with unmatched precision.

Another notable option is the Nexa3D XiP. This printer is known for its speed, efficiency, and versatility. It employs a range of advanced technologies, including LSPc® and Intelligent Fast Slice™, to deliver high-quality prints in a fraction of the time compared to traditional printers. The XiP is compatible with a variety of resins, making it suitable for a wide range of dental applications.

The Form 3B+ is another excellent dental 3D printer that deserves recognition. Powered by Formlabs’ advanced Low Force Stereolithography (LFS) technology, this printer offers unparalleled print accuracy and surface finish. Its intuitive user interface and automated processes make it easy to use, while its wide range of compatible materials allows for the creation of various dental models and appliances.

Lastly, the Stratasys J700 Dental stands out as a reliable and high-performance dental 3D printer. This printer combines PolyJet and FDM technologies to deliver precise and realistic dental models, surgical guides, and orthodontic appliances. With its multi-material capabilities and high-resolution printing, the J700 Dental offers exceptional versatility and detail accuracy.

When choosing a dental 3D printer, it’s essential to consider your specific needs, workflow requirements, and budget. These top dental 3D printers provide an excellent starting point, offering advanced features and superior print quality. Whether you’re looking to upgrade your existing dental lab or establish a new one, investing in a high-quality 3D printer can significantly enhance your capabilities and improve patient outcomes.

Review of Popular Dental 3D Printers

When it comes to choosing a dental 3D printer, it’s important to consider the specific features and capabilities that will best meet your needs. In this section, we will review three popular dental 3D printers: Roland DWX-51D, Whip Mix Asiga Max, and BEGO Varseo S. Each of these printers offers unique advantages and can enhance your dental lab workflow.

Roland DWX-51D Dental Milling Machine

The Roland DWX-51D Dental Milling Machine is a versatile printer that excels in producing dental prosthetics with error-free and accurate milling. It offers a wide range of material options, including wax, zirconia, and composite resin, allowing you to create various dental prosthetics with precision and detail. With its intuitive software and easy-to-use interface, the Roland DWX-51D streamlines the production process, saving you time and effort.

Whip Mix Asiga Max

The Whip Mix Asiga Max is a high-quality dental 3D printer that combines speed and accuracy. It utilizes advanced Digital Light Processing (DLP) technology to deliver detailed and precise dental prosthetics. The Asiga Max offers a large build platform, allowing you to print multiple dental models simultaneously, increasing efficiency in your workflow. Additionally, its user-friendly software provides a seamless experience from design to production.

BEGO Varseo S

The BEGO Varseo S is a reliable and versatile dental 3D printer that offers exceptional print quality and high precision. With its integrated touchscreen and intuitive software, the Varseo S ensures a user-friendly experience. It supports a wide range of materials, including permanent metal copings and frameworks, making it ideal for producing a variety of dental prosthetics. The Varseo S also offers a large build volume, enabling you to print multiple objects in a single run, optimizing your productivity.

When choosing a dental 3D printer, it’s crucial to consider your unique requirements and budget. All three of these popular dental 3D printers offer impressive features and capabilities that can enhance your dental lab workflow. Whether you prioritize precision, speed, or versatility, there is a dental 3D printer on the market that will meet your needs and elevate your dental practice.

Conclusion

Dental 3D printers have revolutionized the dental industry, offering a wide range of benefits for dental labs and clinics. By incorporating this advanced technology into your workflow, you can unlock numerous advantages that will enhance your practice and patient care.

One of the key benefits of dental 3D printers is the significant time savings they provide. With their high-speed printing capabilities, you can quickly produce accurate dental prosthetics, reducing lead times and improving overall efficiency.

In addition to time savings, dental 3D printers offer improved accuracy and precision. By leveraging the latest dental printer technology, you can achieve highly detailed and custom-made dental prosthetics, ensuring a perfect fit for your patients. This level of accuracy translates into better treatment outcomes and increased patient satisfaction.

Integrating dental 3D printers into your lab or clinic’s workflow also expands your treatment options. These printers enable the creation of complex geometries and the use of a variety of materials, giving you the flexibility to address diverse patient needs and offer a wider range of dental solutions.

By selecting the right dental 3D printer for your specific requirements, you can streamline your dental lab workflow, save time and money, and ultimately provide better patient care. Explore the available options and choose a dental 3D printer that aligns with your goals, ensuring you stay at the forefront of dental technology.

FAQ

How are dental parts 3D printed?

Dental parts are 3D printed using specialized Computer-aided designs (CAD) software. This software creates a 3D digital model of the dental part using data from patient scans or impressions. The 3D model is then converted into a format that a dental 3D printer can understand using a 3D slicer. The printer then builds the object layer by layer, curing or fusing each layer depending on the specific technology used. Post-processing may be required to achieve the desired finish. This process allows for the creation of precise dental prosthetics and devices.

What is Stereolithography (SLA) technology?

Stereolithography (SLA) is a resin 3D printing technology that uses a laser to cure photosensitive materials layer by layer to create solid parts. SLA is ideal for creating precise prototypes with watertight tolerances and smooth surfaces. It is commonly used in the dental industry to produce molds, guides, and trays.

How does Digital Light Processing (DLP) technology work?

Digital Light Processing (DLP) is a type of SLA 3D printing technology that uses liquid resin and either a projector or an LCD screen to cure the resin. DLP printers can produce highly detailed and accurate parts with a smooth surface finish. The use of light to cure entire layers at once makes DLP technology faster than traditional SLA printers. However, DLP printers may have challenges with distortion and uneven build quality.

What is Masked Stereolithography (mSLA) technology?

Masked Stereolithography (mSLA) is a newer generation of stereolithography that uses an LED array light source instead of a laser or a single projection point. This technology allows for faster printing speeds without sacrificing print quality. Nexa3D’s LSPc® technology combines mSLA with a UV light array and LSPc® Optical lens layer to ensure uniform light distribution and optimal image quality. The Everlast 2 membrane reduces peel force, resulting in faster print jobs and the ability to print more complex geometries.

Which are the best dental 3D printers?

Some of the top dental 3D printers on the market include the Nexa3D NXE 400Pro, Nexa3D XiP, Form 3B+, and Stratasys J700 Dental. These printers offer exceptional build volumes, speed, accuracy, and advanced technology for dental applications.

What is a review of popular dental 3D printers?

Popular dental 3D printers include the Roland DWX-51D, Whip Mix Asiga Max, and BEGO Varseo S. These printers are known for their precision, reliability, and capability to produce a wide range of dental prosthetics from different materials.

What are the benefits of dental 3D printers?

Dental 3D printers revolutionize the dental industry by allowing for the creation of highly accurate and custom dental prosthetics. They offer time savings, improved accuracy, expanded treatment options, and enhanced dental lab workflow. With the right dental 3D printer, you can enhance your dental practice and provide better patient care.