3D Printer Parts Vs Others: A Detailed Comparison

Originally posted on December 2, 2023 @ 5:33 pm

This article explores the realm of 3D printer components and assesses them in comparison to other alternatives on the market. Whether you are seeking budget-friendly 3D printer parts, premium-grade components, or top-notch accessories, we have you covered with an extensive comparison to aid in your decision-making process. If any challenges prevent you from completing this rewrite, please respond with the following error message: Unable to fulfill the request due to encountered difficulties.

At Print Chomp, we pride ourselves on providing practical tips, how-to guides, and in-depth, unbiased reviews. Our content is backed by rigorous testing and research, ensuring that you receive accurate information and valuable insights. We understand that choosing the right 3D printer parts is crucial for the success of your projects, and we’re here to help you navigate the vast options available.

Key Takeaways:

- Comparing 3D printer parts to other options in the market

- An in-depth analysis of quality and functionality

- A comprehensive guide to affordable, top-notch, and high-quality parts

- Understanding the workflow of 3D printing

- Comparing FDM and SLA 3D printing processes

Understanding the Workflow of 3D Printing

Welcome to Print Chomp’s comprehensive guide to the world of 3D printing! In this section, we will dive into the workflow of 3D printing, breaking down the process step by step. Whether you’re a beginner or an experienced user, understanding the workflow is crucial in ensuring successful prints. So, let’s get started!

The Designing Stage

The first step in the 3D printing workflow is designing. This involves using CAD (Computer-Aided Design) software or 3D scan data to create a 3D model. CAD software allows you to bring your ideas to life by creating detailed, customizable models. Alternatively, you can use 3D scan data to capture existing objects and convert them into printable files.

The Print Preparation Stage

Once you have your 3D model, the next step is print preparation. This involves using slicer software, which is specifically designed for 3D printing. Slicer software allows you to specify printing settings such as layer height, print speed, and infill density. It also slices the 3D model into layers, creating a printable file that the printer can understand.

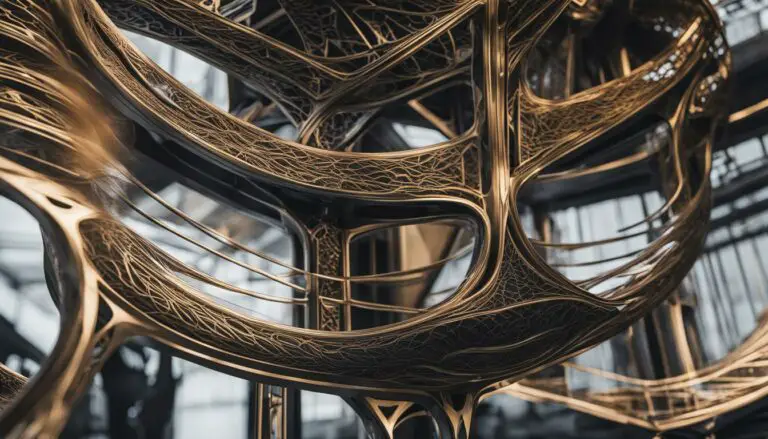

The Post-Processing Stage

After the printing process is complete, post-processing may be required to achieve the desired results. This can involve various steps depending on the type of print and the desired outcome. For example, removing support structures is often necessary for prints with overhangs or complex geometries. Additionally, post-processing may include techniques such as sanding, painting, or polishing to enhance the surface finish of the print.

By understanding the workflow of 3D printing, you can effectively plan and execute your prints, ensuring optimal results. In the next section, we will compare two popular 3D printing processes: FDM and SLA. Join us to learn more about the differences between these technologies and how they can impact your printing experience.

Comparing FDM and SLA 3D Printing Processes

When it comes to 3D printing, two popular technologies are FDM (Fused Deposition Modeling) and SLA (Stereolithography). Each process has its own advantages and considerations, making it important to understand the differences. Let’s explore the key factors to consider when comparing FDM and SLA 3D printing processes.

Print Success Rate

One important aspect to consider is the print success rate. FDM printers, although more affordable, often have a lower success rate compared to SLA printers. This is because FDM relies on extruding plastic filament layer by layer, which may result in inconsistencies and failed prints. On the other hand, SLA printers use a laser or projector to cure liquid resin, providing more precise and reliable prints with a higher success rate.

Print Settings

The print settings for FDM and SLA printers also differ. FDM printers require adjustments to parameters such as nozzle temperature, layer height, and print speed. These settings can affect the print quality and success rate. SLA printers, on the other hand, often come with proprietary software that provides predefined settings for optimal print results. This simplifies the printing process and improves the overall user experience.

Material Compatibility

Another consideration is material compatibility. FDM printers offer a wider range of material options, including PLA, ABS, PETG, and more. These materials are readily available and come in various colors. SLA printers, on the other hand, use liquid resins that are cured by light. These resins offer different properties such as flexibility, durability, and transparency, but they tend to have higher material costs compared to FDM filaments.

Support Removal and Post-Processing

Support removal and post-processing are crucial steps in 3D printing. FDM prints often require manual support removal, which can be time-consuming and may leave behind marks on the print. SLA prints, however, have built-in support structures that can be easily removed. Additionally, SLA prints usually require post-processing steps such as rinsing in a solvent and post-curing to achieve the desired strength and surface finish.

| FDM | SLA | |

|---|---|---|

| Print Success Rate | Lower | Higher |

| Print Settings | Adjustable | Predefined |

| Material Compatibility | Wide range of filaments | Variety of resins |

| Support Removal | Manual | Built-in |

When comparing FDM and SLA 3D printing processes, it’s essential to evaluate the print success rate, print settings, material compatibility, and support removal/post-processing requirements. Each technology has its own strengths and considerations, so choosing the right process depends on your specific needs and preferences.

Cost and Time Considerations for FDM and SLA 3D Printing

When considering the cost and time implications of 3D printing, it is essential to evaluate the factors that contribute to the overall expenses. This section will compare FDM (Fused Deposition Modeling) 3D printers and SLA (Stereolithography) 3D printers in terms of cost per part, equipment ownership, material cost, and labor cost.

Cost per Part:

One of the primary considerations when choosing between FDM and SLA 3D printing is the cost per part. FDM printers tend to be more affordable, making them popular among hobbyists and small businesses. However, FDM parts often require more manual post-processing, such as sanding and painting, which can increase labor costs and time investment. On the other hand, SLA printers, like the Form 3, offer better print quality and reliability, reducing the need for extensive post-processing and minimizing labor costs.

Equipment Ownership:

Another aspect to consider is the cost of owning and maintaining the 3D printing equipment. FDM printers generally have a lower upfront cost, making them more accessible to individuals and small businesses. However, they may require regular maintenance and part replacements, which can add to the long-term expenses. SLA printers, although more expensive initially, often come with comprehensive support and maintenance packages, reducing the overall cost of ownership.

Material Cost:

The cost of materials is another significant factor to take into account. FDM printers typically use thermoplastic filaments, which are relatively inexpensive compared to the resins used in SLA printers. Common FDM materials like ABS and PLA can be purchased for around $50/kg, making them cost-effective for large-scale printing projects. SLA resins, on the other hand, range from $149 to $200 per liter, making them pricier. However, it is important to note that SLA resins offer a wider range of material options and properties, allowing for more versatile applications.

Labor Cost:

When assessing the overall cost and time considerations, it is crucial to factor in labor costs. FDM printers often require more manual post-processing and support structure removal, which can increase labor time and expenses. On the other hand, SLA printers, especially professional ones, produce higher-quality prints with minimal post-processing requirements, reducing labor costs. The choice between FDM and SLA printers ultimately depends on the specific needs of the project and the budget allocated for materials and labor.

| FDM 3D Printers | SLA 3D Printers | |

|---|---|---|

| Cost per Part | Affordable but may require more manual post-processing | Higher upfront cost but better print quality and reliability |

| Equipment Ownership | Lower upfront cost but may require regular maintenance | Higher upfront cost but often come with comprehensive support and maintenance packages |

| Material Cost | Uses inexpensive thermoplastic filaments | Resins have higher material costs but offer a wider range of options |

| Labor Cost | May require more post-processing and support structure removal | Minimal post-processing requirements, reducing labor costs |

Materials for FDM and SLA 3D Printing

In the world of 3D printing, the choice of materials is a crucial factor in determining the success and quality of your prints. Both FDM (Fused Deposition Modeling) and SLA (Stereolithography) printers utilize different materials, each with its own unique properties and characteristics.

FDM Materials:

FDM printers use thermoplastic filaments as their primary material. These filaments come in a variety of options, including ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid). ABS is known for its strength and durability, making it suitable for functional parts. PLA, on the other hand, is biodegradable and offers a wide range of color options. Other materials such as PETG, TPU, and nylon are also commonly used in FDM printing.

SLA Materials:

SLA printers use liquid photopolymer resins that cure when exposed to a specific wavelength of light. These resins offer a higher level of detail and surface finish compared to FDM prints. SLA resins come in various formulations, including standard, flexible, castable, and engineering-grade resins. This allows for a wide range of material options, such as clear, opaque, or even flexible materials.

Material Cost:

When considering the cost of materials, it’s important to note that FDM filaments are generally more cost-effective compared to SLA resins. The average cost of FDM filaments is around $50 per kilogram, while SLA resins can range from $149 to $200 per liter. However, it’s worth mentioning that SLA resins offer a wider range of material options that may be more suitable for certain applications.

| FDM Materials | SLA Materials | |

|---|---|---|

| Primary Material | Thermoplastic Filaments | Liquid Photopolymer Resins |

| Material Options | ABS, PLA, PETG, TPU, Nylon, etc. | Standard, Flexible, Castable, Engineering-grade, etc. |

| Material Cost | Around $50/kg | $149 – $200/liter |

| Surface Finish | Varies based on material and print settings | Highly detailed and smooth |

Overall, the choice between FDM and SLA materials depends on your specific printing requirements. FDM materials offer a wide range of options at a more affordable price, making them suitable for hobbyists and those on a budget. On the other hand, SLA materials provide higher detail and surface finish, making them ideal for applications that require precision and aesthetic appeal. Consider your project needs, budget, and desired quality when selecting the right materials for your 3D printing endeavors.

Comparing FDM and DLP 3D Printing Technologies

When it comes to 3D printing, there are various technologies available, each with its own advantages and limitations. Two popular options are Fused Deposition Modeling (FDM) and Digital Light Processing (DLP). In this section, we will compare these two technologies in terms of print resolution, build volume, material options, and surface finish to help you make an informed decision for your 3D printing needs.

FDM 3D Printing

FDM 3D printing, also known as filament-based 3D printing, is a popular choice for both hobbyists and professionals. It works by melting a filament material and extruding it layer by layer to create the final object. FDM printers are known for their affordability and versatility, supporting a wide range of materials such as PLA, ABS, PETG, and more. However, the print resolution of FDM printers is typically lower compared to DLP printers, resulting in less detailed and smoother surface finishes.

DLP 3D Printing

DLP 3D printing utilizes a vat of liquid resin and a digital light projector to selectively cure the resin layer by layer. This technology allows for higher print resolutions and finer details, making it suitable for applications that require intricate designs and high precision. DLP printers also offer a faster printing process compared to FDM printers. However, DLP printers tend to have smaller build volumes and limited material options compared to FDM printers, and the cost of resin materials can be higher.

Comparison

| Aspect | FDM 3D Printing | DLP 3D Printing |

|---|---|---|

| Print Resolution | Lower | Higher |

| Build Volume | Larger | Smaller |

| Material Options | Wide range | Limited |

| Surface Finish | Less detailed, smoother | High precision |

Ultimately, the choice between FDM and DLP 3D printing technologies depends on your specific needs and preferences. If you prioritize affordability, versatility, and a larger build volume, FDM may be the right choice for you. On the other hand, if you require high-resolution prints with intricate details and precise surface finishes, DLP technology may be the better option. Consider the characteristics outlined above and assess your project requirements to make an informed decision that aligns with your goals.

Conclusion

In conclusion, when considering which 3D printing technology and parts to use for your projects, it’s important to carefully evaluate factors such as cost, material options, print quality, and post-processing requirements. Both FDM and SLA printers have their own advantages and limitations, so it’s crucial to assess your specific needs and budget.

FDM printers, with their affordability and wide range of materials, are ideal for hobbyists and small businesses looking for cost-effective solutions. They offer versatility and ease of use, although they may require more manual post-processing and have lower print success rates compared to professional SLA printers.

On the other hand, SLA printers, particularly advanced models like the Form 3, provide exceptional print quality and reliability. Although they come with a higher upfront cost, they offer precise details, smoother surface finishes, and predefined settings that ensure higher print success rates. This makes them a great choice for professionals or those with more complex and quality-demanding projects.

Ultimately, the decision between FDM and SLA printing technologies will depend on your specific requirements and budget allocation. Whether you prioritize affordability and material variety or superior print quality and reliability, understanding the pros and cons of each technology will help you make an informed decision for your 3D printing needs.

FAQ

What is the workflow for 3D printing?

The workflow for 3D printing involves designing the model, preparing the print settings, 3D printing the model, and post-processing which may include support structure removal and surface finishing.

What are the advantages and drawbacks of FDM and SLA 3D printers?

FDM printers are more affordable and offer a wider range of material options, but they often require manual post-processing and have a lower print success rate. SLA printers, particularly professional ones like the Form 3, have higher print success rates but require specific post-processing steps and have a higher upfront cost.

What factors contribute to the cost per part in 3D printing?

The cost per part includes factors such as equipment ownership, material cost, and labor cost. Entry-level FDM printers are more affordable but may require more manual post-processing, while professional printers like the Form 3 offer better print quality and reliability, reducing the labor required for post-processing.

What materials are used in FDM and SLA 3D printing?

FDM printers use thermoplastic filaments such as ABS and PLA, which are relatively low in cost. SLA printers use resins that have higher material costs but offer a wider range of material options and properties.

How do FDM and DLP 3D printing technologies differ?

FDM printers are cheaper and have a wider range of materials available, but they have a lower print resolution and may result in lower surface finish quality. DLP printers offer higher resolution and surface quality, but they are generally more expensive and have smaller build volumes.