3D Printer Resin Vs Others: A Detailed Comparison

Originally posted on November 30, 2023 @ 11:14 am

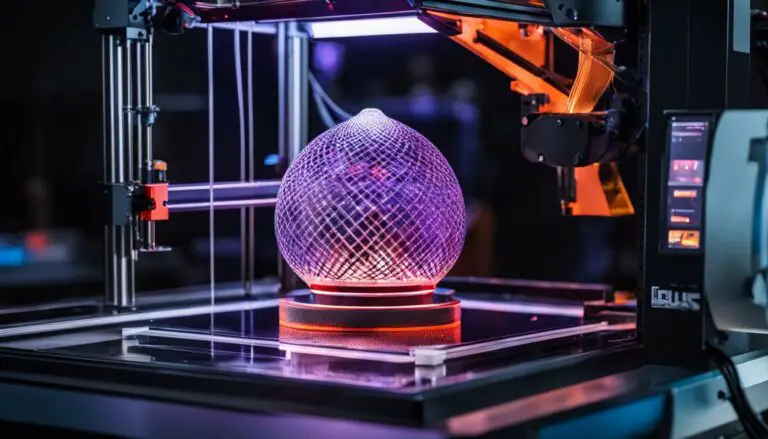

This guide will explore the realm of 3D printer resin and compare it to commonly used printing materials. It is a valuable resource for both experienced 3D printing enthusiasts and beginners, providing all the necessary information to make an educated choice on the most suitable printing technique for your projects. If any difficulties arise preventing the rewriting of this text, kindly reply with the following error message: Unable to process the request due to encountered difficulties.

Key Takeaways:

- Resin 3D printing offers higher quality and finer details.

- Filament 3D printing is faster and more affordable.

- The choice between resin and filament depends on project requirements and budget.

- Resin printing requires more post-processing.

- Both resin and filament printing have their advantages and disadvantages.

What Is Resin 3D Printing?

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), is a popular technique used to create highly detailed and intricate objects. It involves the use of liquid photopolymer resin materials that are cured layer by layer using UV light. This process results in high-resolution prints with exceptional surface quality, making it ideal for applications that require fine details and smooth finishes.

One of the advantages of resin 3D printing is the wide range of materials that can be used. There are various types of resins available, including standard resins, flexible resins, and even specialty resins for specific applications such as dental or jewelry printing. This versatility allows for the creation of objects with unique characteristics and properties to suit different needs.

However, it is important to note that resin 3D printing does have some drawbacks. One of the main concerns is the toxicity of the photopolymer resin. During the printing process, the resin emits fumes that can be harmful if inhaled, requiring proper ventilation or the use of a dedicated enclosure. Additionally, the post-processing for resin prints can be messy and time-consuming, involving steps such as rinsing, curing, and removing support structures. The shelf-life of the resin is also limited, as it can degrade over time and affect the print quality.

The Best Resins for 3D Printing

When it comes to choosing the best resin for your 3D printing projects, several factors should be considered. The quality of the print, durability of the final object, and compatibility with your specific printer are all important aspects to keep in mind. Some of the top-rated 3D printer resins on the market include:

- Resin A: This high-quality resin offers exceptional resolution and produces prints with smooth surfaces. It is suitable for a wide range of applications and is compatible with most SLA and DLP printers.

- Resin B: Known for its durability, Resin B is perfect for creating functional prototypes and parts. It has excellent mechanical properties and can withstand high stress and impact.

- Resin C: If you require flexibility in your prints, Resin C is a great option. It offers a balanced combination of strength and flexibility, making it ideal for applications such as hinges and snap-fit mechanisms.

Choosing the best resin for your 3D printing needs ultimately depends on the specific requirements of your project. It is recommended to do thorough research and choose a reputable manufacturer that offers reliable and high-quality resins for optimal results.

| Resin Type | Features | Applications |

|---|---|---|

| Resin A | High resolution, smooth surface | Artistic models, detailed prototypes |

| Resin B | Durable, strong mechanical properties | Functional prototypes, industrial parts |

| Resin C | Flexible, balanced strength | Hinges, snap-fit mechanisms |

What Is Filament 3D Printing?

Filament 3D printing, also known as fused deposition modeling (FDM), is a popular and accessible method of 3D printing that uses a continuous filament of thermoplastic material to create objects layer by layer. This technology has gained popularity due to its versatility, ease of use, and affordability.

With filament 3D printing, the filament material, usually in the form of a spool, is fed into the 3D printer. The filament is then melted and extruded through a heated nozzle. The heated nozzle moves in a controlled manner, depositing the melted filament material onto a build plate or previously printed layers, creating the desired object or shape. As the material cools down, it solidifies, forming a solid 3D structure.

One of the advantages of filament 3D printing is the wide variety of materials available. Different types of thermoplastic filaments, such as PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), PETG (polyethylene terephthalate glycol), and more, can be used to achieve different properties and characteristics in the printed objects. This allows for flexibility in matching the material properties to the requirements of the specific project.

The Advantages and Disadvantages of Filament 3D Printing

Filament 3D printing offers several advantages that make it a popular choice for both hobbyists and professionals. Some key advantages include:

- Access to a wide range of materials

- Lower cost compared to resin 3D printing

- Ability to print larger objects with a larger build volume

- Durability and strength in the printed objects

However, there are also some disadvantages to consider when using filament 3D printing. These include:

- Visible layer lines on the printed objects

- Slower printing speed compared to resin printing

- Potential for warping or distortion in large prints

- Occasional need for support structures in complex designs

Despite these disadvantages, filament 3D printing remains a versatile and cost-effective option for creating a wide range of objects, prototypes, and functional parts.

Comparison of Resin and Filament Printers

When considering the choice between resin and filament printers, it is essential to weigh the pros and cons of each technology. Resin printers offer higher resolution and a smoother surface finish, making them ideal for intricate and detailed prints. However, resin printing requires more extensive post-processing, including washing, curing, and sanding, which adds to the overall time and effort required.

On the other hand, filament printers are generally more affordable and have larger build volumes, making them suitable for printing larger objects or multiple items at once. Filament printing is also faster than resin printing, allowing for quicker turnaround times. However, filament prints may have visible layer lines, which can impact the overall aesthetic appeal of the final product.

When it comes to cost, filament printers have an advantage. Filament materials are available in a wide range of options, catering to different budgets and specific requirements. Affordable 3D printer resin, on the other hand, can be more expensive, especially if you require premium quality prints. It is crucial to consider your budget and the specific needs of your project when deciding which type of printer to choose.

| Resin Printers | Filament Printers |

|---|---|

| Higher resolution | Visible layer lines |

| Smoothing surface finish | Faster printing speed |

| Requires post-processing | Larger build volumes |

| Potentially more expensive | More affordable |

| SLA Printers | DLP Printers | |

|---|---|---|

| Print Quality | Exceptional surface finish and fine details | Good surface finish and fine details |

| Printing Speed | Slower compared to DLP printers | Faster compared to SLA printers |

| Build Volume | Smaller compared to DLP printers | Larger compared to SLA printers |

| Application | Ideal for intricate models and high-quality prints | Suitable for larger-scale projects |

Workflow and Post-Processing for Resin and Filament Printing

When it comes to workflow and post-processing, both resin and filament printing require several steps to go from the design phase to a finished 3D print. Let’s take a closer look at the processes involved in both methods.

Resin Printing Workflow and Post-Processing

For resin printing, the workflow typically starts with designing the model using CAD software or downloading pre-made designs from online repositories. Once the model is ready, it needs to be prepared for printing using slicer software. The slicer software will generate the necessary toolpaths and supports for the resin printer.

After the preparation stage, the model is sent to the resin printer, where it is printed layer-by-layer using a liquid photopolymer resin. However, the printing process is not the end. Once the print is complete, it requires post-processing to achieve the desired final result.

Post-processing for resin prints involves several steps. First, the printed object needs to be carefully removed from the print bed and rinsed in isopropyl alcohol to remove any excess resin. Then, depending on the specific resin used, the print may need to be cured under UV light to fully harden and strengthen the material. Finally, any support structures used during the printing process need to be removed and any necessary sanding or finishing can be done to achieve a smooth surface finish.

Filament Printing Workflow and Post-Processing

Similar to resin printing, the workflow for filament printing starts with designing the model using CAD software. Once the design is complete, it needs to be prepared for printing using slicer software. The slicer software will generate the necessary toolpaths and supports for the filament printer.

Once the model is prepared, it can be sent to the filament printer for printing. Filament printing involves melting and extruding a thermoplastic filament material, which is then deposited layer-by-layer to create the final object.

Post-processing for filament prints is generally simpler compared to resin prints. After the print is complete, the printed object needs to be carefully removed from the print bed. Depending on the specific print, support structures may need to be removed, leaving behind visible layer lines that may require sanding or finishing to achieve a smoother surface finish.

Choosing the Right Software for Resin Printing

When it comes to resin printing, choosing the right software is crucial for achieving high-resolution models and optimizing the printing process. Some popular software options for resin printing include Chitubox and PrusaSlicer.

Chitubox is a powerful and user-friendly software that allows for efficient and accurate model slicing. It offers features such as hollowing models to save on resin usage, generating supports, and optimizing print settings for different resin types.

PrusaSlicer, developed by the makers of the popular Prusa 3D printers, is another excellent option for resin printing. It offers advanced support generation features and allows for precise control over print parameters, ensuring high-quality prints.

By following the appropriate workflow and utilizing the right software, you can maximize the potential of both resin and filament printing technologies and achieve the best results for your 3D printing projects.

Conclusion

As you weigh the options between resin and filament printing, it’s important to consider your specific needs and requirements. Resin printing offers exceptional print quality with higher resolution and smoother surface finishes, making it ideal for detailed and intricate projects. However, it does require more extensive post-processing, including rinsing, curing, and support removal.

On the other hand, filament printing provides a more affordable solution with larger build volumes, making it suitable for larger-scale projects. Though it may have visible layer lines, filament printing is generally faster and can offer cost-effective results.

Ultimately, your choice between resin and filament printing will depend on factors such as your desired print quality, budget, and project requirements. Whether you opt for high-quality resin for 3D printers or affordable resin for your budget, Print Chomp is here to provide you with practical tips, unbiased reviews, and in-depth guides to help you make the right decision for your 3D printing needs.

FAQ

What is the difference between resin 3D printing and filament 3D printing?

Resin 3D printing uses liquid resin material that is cured by UV light to create objects, while filament 3D printing uses melted plastic filament extruded through a hot nozzle.

What are the advantages of resin 3D printing?

Resin 3D printing offers higher resolution, smoother surface finishes, and a wide range of materials to choose from.

What are the advantages of filament 3D printing?

Filament 3D printing is generally more affordable, has larger build volumes, and offers a variety of materials and durability.

What are the main types of resin 3D printers?

The main types of resin 3D printers are stereolithography (SLA) and digital light processing (DLP).

What is the workflow for resin and filament printing?

The workflow involves designing the model using CAD software, preparing the model for printing with slicer software, and then printing the model using the appropriate 3D printer.

What post-processing steps are involved in resin printing?

Resin prints require post-processing steps such as rinsing in isopropyl alcohol, curing, and support removal.

What post-processing steps are involved in filament printing?

Filament prints may require support structure removal and additional post-processing for a high-quality finish.

How do I choose between resin and filament printing?

The choice depends on factors such as desired print quality, cost, ease of use, and specific project requirements.