Cool 3D Prints Vs Others: A Detailed Comparison

Originally posted on November 28, 2023 @ 10:47 am

This article will thoroughly examine the realm of fascinating 3D printing and contrast it with other printing techniques. If you’re searching for distinctive 3D printed objects, innovative concepts, or the top 3D printed creations, we have everything you need. Let’s assess the advantages and disadvantages of various printing approaches, and uncover what distinguishes exciting 3D prints from others.

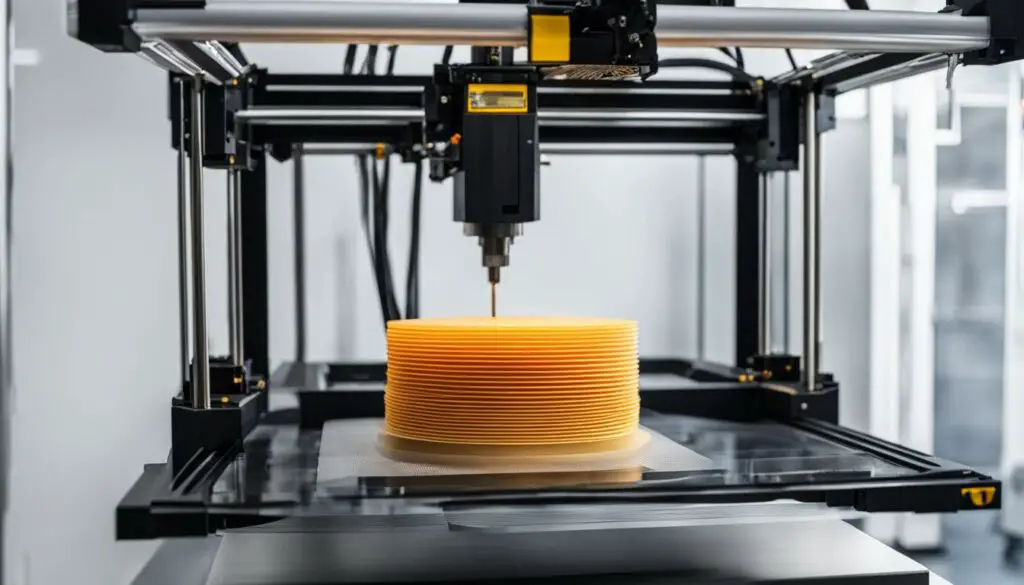

3D printing, also known as additive manufacturing, has taken the world by storm. It’s a process that allows you to create three-dimensional objects by building them layer by layer using a digital model. The possibilities offered by 3D printing are vast, from prototyping and functional parts to artistic creations and jewelry design. But how do cool 3D prints compare to other printing technologies? Let’s find out.

Key Takeaways:

- Cool 3D prints open up endless possibilities for creativity and innovation.

- Resin printing technologies offer exceptional print quality and fine details.

- Filament printing with FDM technology provides durability and strength.

- The choice between resin and filament printing depends on your specific needs and project requirements.

- Experiment with different materials and designs to create the best 3D printed objects.

How 3D Printing Works

3D printing, also known as additive manufacturing, is a fascinating process that allows you to bring your digital designs to life. It starts with a digital model created using 3D modeling software or obtained through scanning an existing object. This digital model is then sliced into thin cross-sectional layers, which serve as the blueprint for the 3D printer.

There are various 3D printing technologies available, each with its own unique process and materials. For example, Fused Deposition Modeling (FDM) technology uses thermoplastic filament that is melted and deposited layer by layer to create the final object. On the other hand, Masked Stereolithography (MSLA) and Digital Light Processing (DLP) technologies use liquid resin that is cured by UV light to produce precise and detailed prints.

When it comes to materials, the options are vast. 3D printers can work with a range of materials including plastics like ABS and PLA, metals like titanium and stainless steel, and even food substances like chocolate and sugar. The choice of material depends on the specific requirements of your project, such as strength, flexibility, and heat resistance.

| Printing Technology | Main Process | Main Materials |

|---|---|---|

| Fused Deposition Modeling (FDM) | Melting and deposition of thermoplastic filament | ABS, PLA, nylon, PETG |

| Masked Stereolithography (MSLA) | Curing of liquid resin using UV light | Photopolymer resin |

| Digital Light Processing (DLP) | Curing of liquid resin using UV light | Photopolymer resin |

As you can see, the world of 3D printing offers endless possibilities. Whether you’re a hobbyist, an artist, or an engineer, 3D printing allows you to turn your ideas into reality. By understanding how 3D printing works and exploring the different technologies and materials available, you can make the most of this innovative technology and unlock your creative potential.

Comparing Resin and Filament Printing Technologies

When it comes to 3D printing, two popular technologies stand out: resin printing and filament printing. Understanding the differences between these two methods is crucial in choosing the right one for your project. Let’s take a closer look at resin 3D printing and filament 3D printing and compare their key characteristics.

Resin 3D Printing

Resin 3D printing, also known as SLA (Stereolithography) printing, utilizes a liquid resin that is cured by UV light to create precise and highly detailed prints. This technology offers exceptional print quality with smooth surface finishes, making it ideal for applications that require intricate details, such as jewelry or dental models. However, resin prints can be prone to brittleness and may lack the durability needed for functional parts.

Filament 3D Printing

Filament 3D printing, specifically FDM (Fused Deposition Modeling), is another popular option. In this process, thermoplastic filament is melted and deposited layer by layer to build the desired object. FDM prints are known for their strength and durability, making them suitable for functional parts and prototypes. While they may have visible layer lines, post-processing techniques can be used to improve the surface finish.

| Resin Printing | Filament Printing | |

|---|---|---|

| Print Quality | High resolution and smooth surface finish | Visible layer lines, may require post-processing |

| Durability | Brittle and less durable | Strong and durable |

| Material Options | Limited range of resin materials | Wide variety of thermoplastic filaments |

| Build Volume | Smaller build areas | Larger build volumes |

As shown in the table above, resin printing excels in print quality and surface finish, while filament printing offers greater durability and material options. The choice between the two technologies ultimately depends on your specific needs and project requirements.

Consider the details you need to capture in your prints and the level of durability required. If you prioritize intricate details and a smooth finish, resin printing may be the right choice. On the other hand, if strength and durability are crucial, filament printing is the better option. Evaluate the available materials for each technology and their specific properties to ensure they align with your project requirements.

By comparing the pros and cons of resin and filament printing technologies, you can make an informed decision and achieve the desired results for your 3D printing projects.

Choosing the Right Technology for Your Needs

When it comes to 3D printing, choosing the right technology is essential to ensure that your projects meet your specific requirements. Factors such as print quality, material selection, and build volume play a crucial role in making the right decision. Let’s dive deeper into these considerations to help you select the best technology for your 3D printing needs.

Print Quality

The quality of the prints is a primary concern for many 3D printing enthusiasts. Resin printers, such as SLA and DLP, offer exceptional print quality with smooth surface finishes and fine details. These technologies are perfect for applications that require high-resolution prints, such as jewelry or artistic creations. On the other hand, filament printers, like FDM, may have visible layer lines but offer excellent strength and durability. If your project requires functional parts or prototypes, filament printing technology might be the better choice.

Material Selection

Another crucial aspect to consider when choosing a 3D printing technology is the range of materials available. Resin printers typically offer a limited selection of specialized resins, each with unique properties. For example, dental resins are specifically designed for dental applications, while castable resins are used in the jewelry industry. Filament printers, on the other hand, provide a wider range of materials, including various thermoplastics such as ABS and PLA, as well as specialty filaments like carbon fiber or flexible materials. Consider the specific characteristics and requirements of your project to determine which technology offers the most suitable material options.

Build Volume

The build volume, or the maximum size of the objects you can print, is an important factor to consider, especially for larger projects. Resin printers typically have smaller build volumes compared to filament printers. If you need to print larger objects or multiple parts in a single print, filament printing technology might be more suitable. However, if you primarily work on smaller, intricate designs, such as jewelry or miniatures, the limited build volume of resin printers might not be a significant concern.

| Resin Printing | Filament Printing | |

|---|---|---|

| Print Quality | Exceptional quality with smooth surface finish and fine details | Visible layer lines, but offers excellent strength and durability |

| Material Selection | Limited range of specialized resins | Wide variety of thermoplastics and specialty filaments |

| Build Volume | Smaller build area, suitable for smaller, intricate designs | Larger build area, suitable for bigger projects |

Ultimately, the right choice between resin and filament printing technologies depends on your project requirements and priorities. Assess the desired print quality, material options, and build volume needed for your projects to make an informed decision. Whether you prioritize the finest details or robust functionality, there is a 3D printing technology that suits your needs.

Conclusion

In conclusion, 3D printing offers a whole new level of creativity and innovation, allowing you to bring your ideas to life. With the ability to print cool things like unique designs, trendy objects, and popular creations, the possibilities are endless.

Whether you choose resin printing with SLA or DLP technology for exceptional print quality and fine details, or filament printing with FDM technology for durability and strength, your cool 3D prints will definitely stand out from the crowd.

At Print Chomp, we understand the importance of staying up-to-date with the latest trends and technologies in the 3D printing world. Our technology blog provides practical tips, how-to guides, and in-depth, unbiased reviews backed by rigorous testing and research.

So, start exploring the world of 3D printing and unleash your creativity with innovative and trendy prints. From artistic masterpieces to functional parts, cool 3D prints are waiting to be brought to life by you!

FAQ

What is 3D printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by building them layer by layer using a digital model.

How does 3D printing work?

3D printing starts with a digital model created using 3D modeling software or obtained through scanning an existing object. The model is then sliced into thin cross-sectional layers, which are sent to the 3D printer. The printer then builds the object layer by layer, using various materials such as ABS plastic, PLA, titanium, or even food substances like chocolate or sugar.

What are the different printing technologies used in 3D printing?

Different printing technologies, such as Fused Deposition Modeling (FDM), Masked Stereolithography (MSLA), and Digital Light Processing (DLP), each have their own unique printing process and materials. These technologies offer different capabilities and output quality, allowing for a wide range of possibilities in 3D printing.

What is resin 3D printing?

Resin 3D printing, also known as vat photopolymerization, uses liquid resin that is cured by UV light to create precise and detailed prints. It offers high resolution and smooth surface finish, making it ideal for applications that require intricate details.

What is filament 3D printing?

Filament 3D printing, such as Fused Deposition Modeling (FDM), uses thermoplastic filament that is melted and deposited layer by layer to create prints. FDM prints are known for their strength and durability, making them suitable for functional parts and prototyping.

Which printing technology should I choose?

When choosing between resin and filament printing technologies, it’s essential to consider your specific needs and project requirements. If you prioritize high-resolution prints with a smooth surface finish, resin printing is the way to go. However, if you need durable and functional parts, filament printing is the better option. Consider the materials available for each technology and their properties, such as heat resistance, chemical resistance, and flexibility. Also, take into account the build volume needed for your project, as resin printers tend to have smaller build areas compared to filament printers.

What are the advantages of resin 3D printing?

Resin 3D printing offers exceptional print quality and fine details, making it suitable for artistic, jewelry, and dental applications. It provides high resolution and a smooth surface finish.

What are the advantages of filament 3D printing?

Filament 3D printing, such as FDM technology, offers durability and strength, making it a preferred choice for industrial and functional parts. It provides strong and durable prints.

What are the factors to consider when choosing a 3D printing technology?

When choosing a 3D printing technology, consider your specific needs, desired print quality, and project requirements. Evaluate the available materials and their properties, as well as the build volume needed for your project.