Essential 3D Printed Bong Checklist For Enthusiasts

Originally posted on December 7, 2023 @ 12:20 am

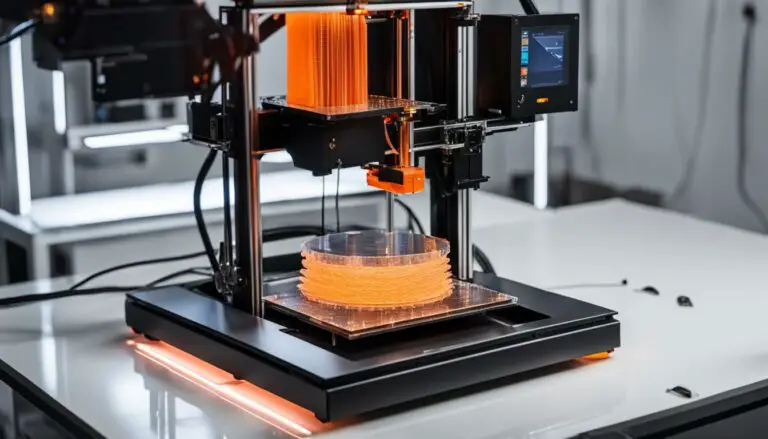

This piece will delve into the realm of 3D printed bongs and examine the reasons behind their rise in popularity among cannabis enthusiasts. As the cost of 3D printers continues to decrease, an increasing number of individuals are recognizing the advantages of crafting their own unique, top-notch, and personalized 3D printed bongs. From inventive styles to long-lasting materials, there are many factors to take into account when exploring the world of 3D printed cannabis equipment.

Key Takeaways

- 3D printing offers rapid design and prototyping capabilities for creating unique and customizable bongs.

- Ceramic water pipes are a popular choice for 3D printed bongs due to their heat resistance and smooth finish.

- Small-batch production and modifications are more cost-effective with 3D printing compared to traditional injection molding.

- Endless artistic and customizable designs can be found on platforms like Thingiverse and Yeggi.

- Accessory holders for dabbing tools are also created using 3D printing technology, providing functional and stylish options for organization.

Benefits of 3D Printed Bongs

The world of 3D printing has revolutionized the manufacturing industry, and it has now made its way into the cannabis community. The emergence of 3D printed bongs offers numerous benefits for enthusiasts seeking innovative and durable smoking accessories.

One of the key advantages of 3D printed bongs is the ability to create unique and personalized designs. With 3D printing, you have the freedom to experiment with different shapes, patterns, and textures, resulting in a truly one-of-a-kind smoking experience. Whether you prefer a sleek and modern design or a more intricate and artistic piece, 3D printing allows you to bring your vision to life.

Furthermore, 3D printing enables faster production and customization compared to traditional manufacturing methods like injection molding. This means that small-batch production and modifications can be done more efficiently and cost-effectively. With 3D printing, you can easily tweak and refine your bong design until it meets your exact specifications, ensuring that you get a high-quality product tailored to your preferences.

“3D printed bongs allow for endless possibilities in design and customization, making each piece a unique work of art.” – Cannabis Enthusiast

When it comes to durability, the material used plays a crucial role. Ceramic water pipes are a popular choice for 3D printed bongs due to their heat resistance and smooth finish. These bongs not only provide a satisfying smoking experience but also stand the test of time. The precise nature of 3D printing ensures that every detail of the design is accurately reproduced, resulting in a sturdy and reliable product that can withstand regular use.

Benefits of 3D Printed Bongs:

- Unique and personalized designs

- Faster production and customization

- Durable and long-lasting

With the advantages of customization, efficiency, and durability, it’s no wonder why 3D printed bongs are gaining popularity among cannabis enthusiasts. As technology continues to advance, we can expect even more innovative and groundbreaking designs in the world of 3D printed cannabis gear.

Customization Options for 3D Printed Bongs

When it comes to 3D printed bongs, one of the greatest advantages is the endless customization options available. With 3D printing, you have the ability to create unique and artistic designs that reflect your personal style. Whether you’re looking for a bold and vibrant bong or a sleek and minimalist piece, 3D printing offers the flexibility to bring your vision to life.

Platforms like Thingiverse and Yeggi provide a vast library of free creative commons files for printable 3D models, including artistic bong designs. These platforms allow you to browse through a wide range of options, from intricate patterns to intricate designs, in search of the perfect fit for your preferences. You can also find online forums, groups, videos, and articles that provide guidance and support for those interested in exploring 3D printing and customization.

For those who prefer to leave the 3D printing to the experts, there are online businesses that specialize in creating custom 3D printed cannabis gear. These businesses offer a variety of options for personalization, allowing you to choose from different materials, colors, and finishes. Whether you’re looking for a one-of-a-kind artistic bong or a customized version of a popular design, these services can help you create a truly unique piece.

When it comes to creating your own designs, the only limit is your imagination. With 3D printing, you can experiment with different shapes, sizes, and textures to create a bong that perfectly suits your needs. Whether you want a bong with built-in storage compartments, an ergonomic grip, or a unique filtration system, 3D printing allows you to bring your ideas to life. The ability to customize every aspect of your bong ensures that you’ll have a smoking experience that is tailored to your preferences.

Table: Comparison of Customizable 3D Printed Bongs

| Bong | Material | Customization Options | Price Range |

|---|---|---|---|

| Artistic Masterpiece | Ceramic | Unlimited designs and patterns | $100-$500+ |

| Minimalist Elegance | Glass | Customizable size and shape | $50-$200 |

| Futuristic Innovation | Plastic | Integrated features and compartments | $30-$100 |

“With 3D printing, you have complete control over the design process. You can create a bong that is truly unique to you, reflecting your personality and style. It’s like having a piece of functional art in your hands.” – Jane Doe, 3D Printing Enthusiast

Accessory Holders for Dabbing Tools

If you’re a dabbing enthusiast, you know how important it is to keep your dab tools organized and easily accessible. That’s where 3D printed accessory holders come in handy. These holders are specifically designed to hold a variety of dabbing tools, from dab tools and cappers to storage containers and even essential items like lighters and chapstick. With 3D printing technology, you can now find functional and stylish options to keep your dabbing tools organized in one place.

Companies like Printabowl and Zabo Designs are at the forefront of creating innovative and customizable 3D printed accessory holders for dabbing tools. These holders not only provide a practical solution for organizing your tools but also add a touch of style to your dabbing setup. Whether you prefer a sleek and minimalistic design or a bold and artistic one, you can find a wide range of options to suit your personal taste and preferences.

“Having a dedicated accessory holder for your dabbing tools not only keeps everything organized but also adds a visual appeal to your smoking setup.”

With 3D printed dab tool holders, you can say goodbye to the hassle of searching for your tools or having them scattered around. These holders are designed to keep everything in one place, making it quick and easy to find the tools you need for your dabbing sessions. Plus, the customizable nature of 3D printing allows you to add personalized touches to your accessory holder, making it truly unique to you.

So, if you’re tired of losing your dabbing tools or simply want to add some organization and style to your setup, consider investing in a 3D printed dab tool holder. With a wide variety of options available, you’re sure to find one that suits your needs and enhances your dabbing experience.

Considerations for 3D Printing with Clay

When it comes to 3D printing with clay, there are a few important considerations to keep in mind. Clay ceramics are a popular choice for 3D printed bongs due to their heat resistance and smooth finish. However, to ensure successful printing, the consistency of the clay is crucial. It should be uniform and free from any lumps or air pockets that could affect the extrusion process.

Another factor to consider is the shrinkage rate of the clay. Shrinkage is a natural occurrence during the firing process and can cause the final printed object to be smaller than the original design. To compensate for this shrinkage, adjustments may need to be made to the size of the model before printing. It’s important to take these shrinkage rates into account to ensure the final printed object meets your desired specifications.

Additionally, different types of clay may have different properties and behaviors when it comes to 3D printing. It’s important to choose a clay that is specifically formulated for 3D printing to achieve the best results. Some clays are designed to have a higher water content, which can make them easier to work with during the printing process.

Overall, 3D printing with clay offers unique opportunities for creating customized and artistic designs. By carefully considering the type of clay, its consistency, and the shrinkage rates, you can ensure a successful and high-quality 3D printed bong that meets your specific needs and preferences.

Table: Recommended Clay for 3D Printing

| Type of Clay | Properties | Recommended Usage |

|---|---|---|

| Polymer Clay | Easy to work with, versatile, and available in various colors. Requires baking to harden. | Small decorative elements and details. |

| Earthenware Clay | Porous and lightweight. Requires glazing and firing at low temperatures. | Functional objects like cups, bowls, and vases. |

| Porcelain Clay | Smooth and translucent. Requires firing at high temperatures to achieve strength. | Delicate and intricate designs. |

Conclusion

3D printed bongs offer a plethora of benefits and customization options for cannabis enthusiasts. The accessibility and affordability of 3D printers have revolutionized the industry, making it a popular choice for professionals and hobbyists alike. Whether you are a seasoned designer or a curious beginner, 3D printing allows you to create unique and personalized smoking gear that enhances your cannabis experience.

With the ability to rapidly iterate designs and incorporate innovative features, 3D printed bongs provide endless possibilities. You can unleash your creativity by exploring a vast library of 3D models or even designing your own. From intricate and artistic pieces to functional and durable designs, 3D printing allows you to bring your imagination to life.

For those who prefer to leave the printing to the experts, there are online businesses specializing in creating custom 3D printed cannabis gear. These professionals can translate your vision into a high-quality, personalized bong that perfectly suits your needs and preferences.

Whether you decide to embark on a DIY adventure or entrust your design to professionals, 3D printed bongs and accessory holders are sure to elevate your smoking experience. Embrace the world of 3D printing and unlock a whole new level of customization and innovation in the world of cannabis gear.

FAQ

Are 3D printed bongs durable?

The durability of 3D printed bongs depends on the material used. Ceramic water pipes, often used for 3D printed bongs, offer superior heat resistance and a smooth finish, making them a durable option.

Can I customize my 3D printed bong?

Yes, 3D printing allows for rapid design iteration and customization. Whether you create your own designs or rely on experts, you can personalize your 3D printed bong to suit your preferences.

What can I use 3D printing for besides bongs?

3D printing is not limited to bongs. It can also be used to create accessory holders for dabbing tools, including dab tools, cappers, storage containers, and even essentials like lighters and chapstick.

Where can I find 3D printable models for my 3D printer?

There are platforms like Thingiverse and Yeggi where you can find a wide range of free creative commons files for printable 3D models. You can also find guidance and support on online forums, groups, videos, and articles.

What should I consider when 3D printing with clay?

When using clay for 3D printing, consider the type of clay, its consistency, and shrinkage rates. Clay ceramics are popular for 3D printed bongs due to their heat resistance and smooth finish. The consistency of clay should be uniform for even extrusion during printing, and adjustments may need to be made to compensate for shrinkage during the firing process.