Explore the World of 3D Printers Technology – Forge Your Future

Originally posted on November 17, 2023 @ 1:32 pm

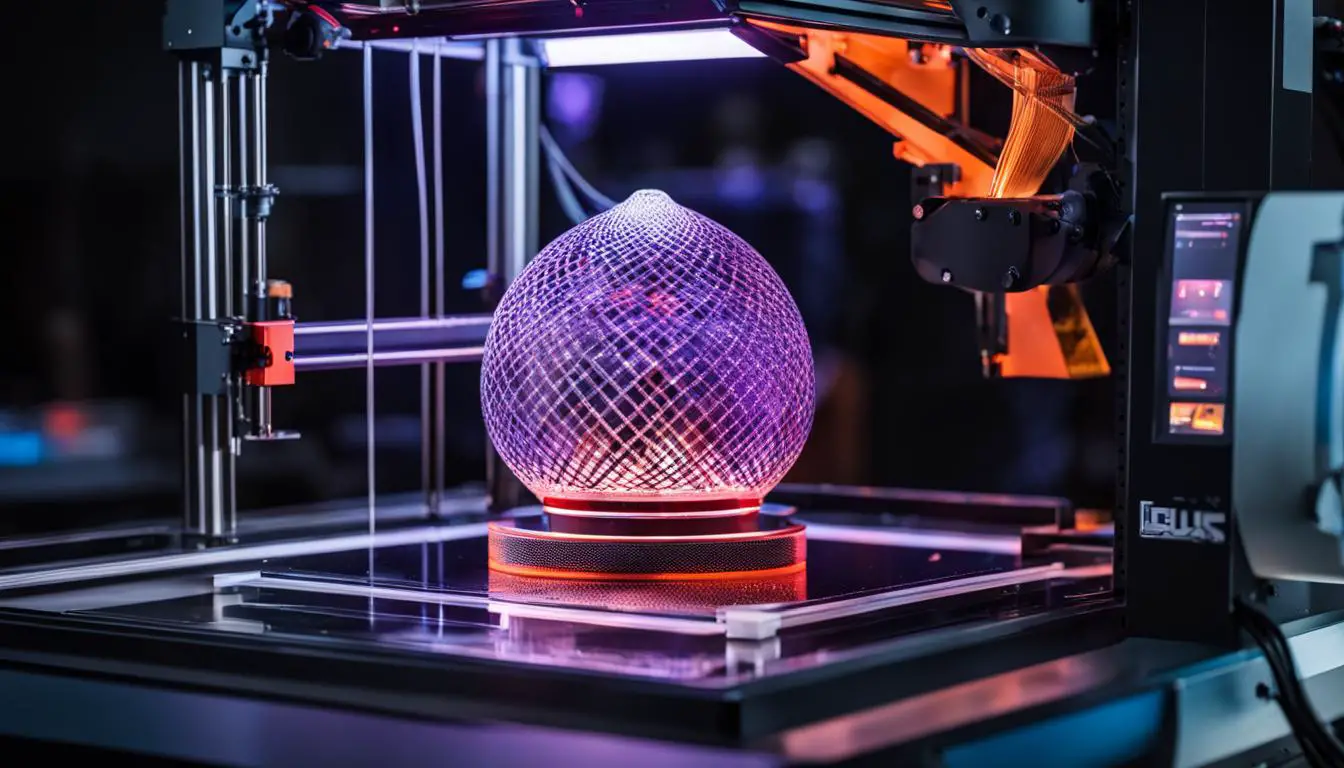

Welcome to the dynamic realm of 3D printing technology! In recent years, the continuous advancements in this field have been changing industries and opening up new possibilities. From manufacturing to medicine and construction, the impact of 3D printing is limitless. This article will explore the various ways that 3D printing is revolutionizing our future and transforming different sectors. Get ready to uncover the incredible innovations that await in the world of 3D printing technology.

Key Takeaways:

- 3D printing is rapidly advancing and has the potential to revolutionize industries.

- Manufacturing can become more localized and cost-effective with 3D printing technology.

- The medical field benefits from 3D printing with the creation of prosthetics and bioprinting.

- 3D printing in construction can address affordability issues and utilize recycled materials.

- The future of 3D printing holds numerous possibilities in various sectors, including healthcare, manufacturing, and sustainability.

The Impact of 3D Printing on Manufacturing

3D printing technology has the potential to revolutionize the manufacturing industry. With advanced and cutting-edge 3D printers, companies can now manufacture products in-house, reducing the need for outsourcing. This not only saves costs but also allows for more control over the manufacturing process.

Moreover, as 3D printing technology becomes more affordable and accessible, it enables inventors and creatives to turn their ideas into realities. With the ability to rapidly prototype and iterate designs, they can bring new products to market faster than ever before. From intricate and customized parts to functional prototypes, the possibilities are endless.

Imagine a future where store shelves are filled with various 3D-printed products that were once unimaginable. Companies can quickly adapt to changing consumer demands and create unique products that cater to individual preferences. This level of customization and flexibility can disrupt traditional manufacturing models and reshape the way we produce and consume goods.

Advantages of 3D Printing in Manufacturing:

- Reduced costs: 3D printing eliminates the need for expensive tooling and molds, making it cost-effective for small-scale production and customization.

- Faster time to market: With rapid prototyping capabilities, companies can iterate and refine their designs quickly, reducing time-to-market for new products.

- Complex geometries: 3D printing enables the production of intricate and complex designs that would be difficult or impossible with traditional manufacturing methods.

- Sustainability: By using additive manufacturing processes, 3D printing generates less waste compared to subtractive manufacturing methods.

“3D printing has the potential to transform the manufacturing landscape, enabling companies to reduce costs, increase customization, and accelerate innovation.”

As the technology behind 3D printing continues to advance, we can expect even more breakthroughs in manufacturing. From aerospace and automotive industries to consumer products and beyond, the impact of 3D printing will be felt across various sectors, driving innovation and shaping the future of manufacturing.

3D Printing in the Medical Field

3D printing technology has made significant advancements in the medical field, offering innovative solutions and improving patient care. One of the key areas where 3D printing is making a difference is in the creation of prosthetics. Traditional prosthetics can be expensive and time-consuming to manufacture, making them inaccessible to many people. However, with 3D printing, prosthetics can be custom-made at a lower cost, making them more affordable and readily available to those in need. This technology has already transformed the lives of amputees, providing them with functional and personalized prosthetic limbs.

In addition to prosthetics, bioprinting is another groundbreaking application of 3D printing in medicine. Bioprinting uses human cells and tissues as “ink” to create three-dimensional structures that mimic organs or body parts. This technology has the potential to revolutionize surgery by allowing for the creation of 3D-printed organs that can be transplanted into patients. While the development of fully functional organs is still a work in progress, researchers are making significant strides in this field. In the near future, 3D-printed organs could address the shortage of donor organs and provide life-saving treatments to patients.

Another exciting advancement in 3D printing in medicine is the production of 3D-printed pills. This technology enables the creation of customized medications with precise dosages for individual patients. Unlike traditional pills, which are mass-produced and come in standardized dosages, 3D-printed pills can be tailored to meet the specific needs of each patient. This not only improves medication adherence but also opens up possibilities for personalized medicine and more effective treatments.

| Benefits of 3D Printing in Medicine |

|---|

| Accessible and affordable prosthetics |

| Potential for 3D-printed organs |

| Precision and customization in medication |

3D printing in the medical field holds immense potential for improving patient care, advancing surgical procedures, and transforming the healthcare industry. With ongoing advancements in technology and increased accessibility, we can expect to see further innovation and integration of 3D printing into medical practices. From prosthetics to bioprinting and personalized medications, 3D printing is revolutionizing healthcare and paving the way for a future where medical treatments are more effective, accessible, and tailored to individual patients.

3D Printing in the Construction Industry

3D printing technology is not only revolutionizing the manufacturing and healthcare sectors, but it is also making its way into the construction industry. With its potential to address rising housing prices and affordability issues, 3D printing has the power to transform the way we build and design structures.

Companies like Winsun have already begun utilizing 3D printing technology to construct houses at a fraction of the cost of traditional methods. By using recycled materials and reducing transportation costs, 3D printing in construction can significantly reduce construction expenses and make housing more accessible. This innovation opens doors for affordable housing solutions and sustainable building practices.

One of the key advantages of 3D printing in construction is the ability to create customized designs and structures. Architects and designers can use 3D printers to bring their visions to life, allowing for intricate designs and unique architectural features that were once challenging to achieve. This level of customization enhances creativity and pushes the boundaries of what is possible in the construction industry.

Table: Examples of 3D Printing in Construction

| Company | Project | Description |

|---|---|---|

| Winsun | 3D-printed houses | Using a large-scale 3D printer, Winsun has successfully printed multiple houses using recycled materials, reducing costs and construction time. |

| MX3D | 3D-printed bridge | MX3D collaborated with designers, engineers, and roboticists to create a 3D-printed steel bridge across a canal in Amsterdam, showcasing the possibilities of 3D printing in large-scale construction projects. |

| Apis Cor | 3D-printed house in 24 hours | Apis Cor has developed a 3D printer that can construct a small house in just 24 hours, demonstrating the speed and efficiency of 3D printing technology in residential construction. |

As 3D printing technology continues to advance, we can expect further advancements in construction. The potential to speed up construction projects, reduce costs, and create sustainable and customized designs makes 3D printing a promising innovation for the future of the construction industry.

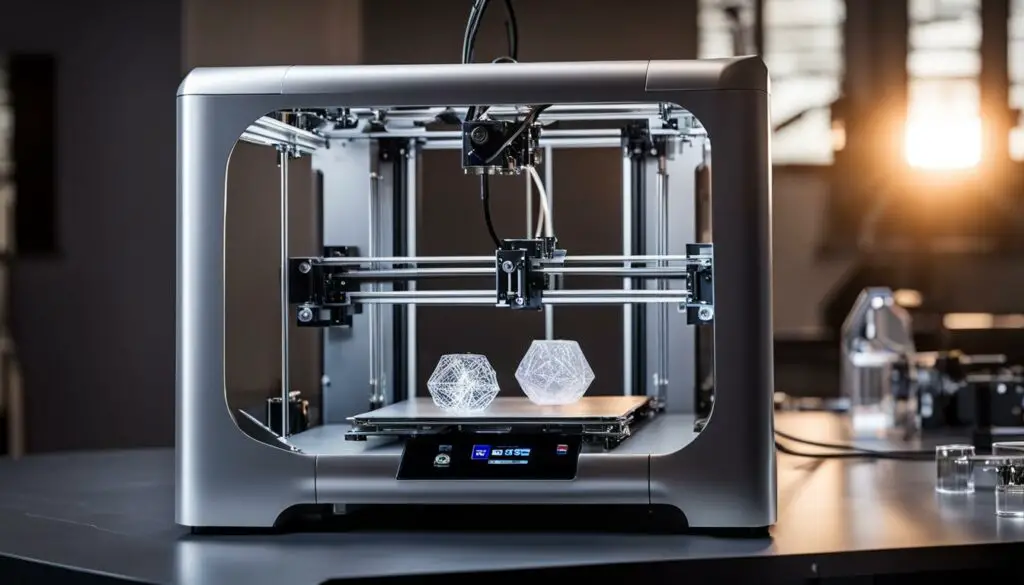

Future Implications of 3D Printing

The future of 3D printing holds tremendous possibilities and innovations that will continue to shape various industries. As technology advances, we can expect to see further advancements in manufacturing, healthcare, construction, and environmental sustainability.

Manufacturing Revolution

In the manufacturing industry, companies are already transforming their operations by creating “digital warehouses” of printable parts and tools. This approach allows for greater efficiency and flexibility in production processes. With advanced 3D printers, businesses can rapidly prototype and customize products, saving time and reducing costs. In the future, we may see a shift toward localized production, eliminating the need for extensive supply chains and reducing the carbon footprint associated with transporting goods.

Medical Breakthroughs

In healthcare, the potential of 3D printing is significant. Prosthetics that are more mechanically viable and cost-effective are already benefiting individuals with limb loss. The field of bioprinting is making remarkable progress, with the potential to create 3D-printed organs and tissues. This development could revolutionize organ transplantation and significantly improve patient outcomes. Moreover, the production of 3D-printed pills has the potential to increase access to medication, especially in remote or underserved areas.

Transforming Construction

The construction industry is also set to experience transformation through the use of 3D printing technology. Companies like Winsun have already demonstrated the capability of printing houses at a fraction of the cost of traditional construction methods. By using recycled materials and reducing waste, 3D printing has the potential to address affordability and sustainability challenges in the housing sector. Customized fixtures and components can be quickly printed on-site, saving time and resources.

| Innovation | Impact |

|---|---|

| 3D-printed houses | Affordable and sustainable housing solutions |

| Bioprinting | Creation of functional organs and tissues for transplantation |

| Localized production | Reduction of supply chain complexity and carbon footprint |

Overall, the future of 3D printing holds immense potential for innovation and positive change across industries. As advancements continue, we can anticipate more cost-effective manufacturing processes, groundbreaking developments in healthcare, and environmentally sustainable solutions in construction. It is an exciting time to witness the transformative power of 3D printing and its impact on shaping our future.

The Transformation of Industries through 3D Printing

3D printing technology has already had a profound impact on various industries, with its numerous benefits and innovative applications. This revolutionary technology offers cost-effective experimentation, rapid prototyping, and customizable tooling, allowing companies to bring their ideas to life in a more efficient and creative way.

In the healthcare industry, 3D printing has enabled significant advancements, particularly in the creation of prosthetics, dental assistances, and replacement joints. By leveraging the flexibility and precision of 3D printing, healthcare professionals can provide patients with personalized and mechanically viable solutions that enhance their quality of life.

“We have seen remarkable progress in the field of 3D printing, especially in the medical sector. The ability to create customized prosthetics and implants has revolutionized patient care and improved outcomes.”

Educational institutions have also embraced 3D printing as a means to encourage creativity and exploration among students. With 3D printers accessible in classrooms, students can turn their ideas into tangible objects, fostering a hands-on learning experience that ignites their curiosity and innovation.

Retailers and designers are continuously exploring the possibilities offered by 3D printing. This technology allows them to push the boundaries of product design and create unique, customizable products that were once unimaginable. From intricate jewelry pieces to architectural models, 3D printing has opened up new avenues for creativity and customer engagement.

The Transformative Power of 3D Printing in Industries

The transformative power of 3D printing is not limited to specific sectors but extends to various industries. This technology has enabled the creation of 3D-printed houses, tools for space exploration, and even garments for high-profile events. The possibilities are endless, as companies and individuals continue to push the boundaries of what can be achieved with 3D printing.

| Industry | Impact of 3D Printing |

|---|---|

| Manufacturing | Cost-effective experimentation, rapid prototyping, and customizable tooling |

| Healthcare | Personalized prosthetics, dental assistances, and replacement joints |

| Education | Encouraging creativity and exploration among students |

| Retail and Design | Pushing the boundaries of product design and customization |

As 3D printing technology continues to evolve and become more accessible, we can expect to witness further transformative changes across industries. The future holds even more exciting innovations and applications for this groundbreaking technology, creating endless possibilities for businesses and individuals alike.

The Future of 3D Printing in Different Sectors

The future of 3D printing holds tremendous potential in various sectors. As technology continues to advance, 3D printing is poised to revolutionize industries such as manufacturing, healthcare, construction, sustainability, and automotive.

Manufacturing:

Companies are embracing the concept of digital warehouses, where printable parts and tools can be stored and accessed on demand. This shift in operations allows for cost-effective experimentation, rapid prototyping, and customizable tooling. In the future, manufacturers may rely less on traditional supply chains and instead produce their own parts locally, reducing costs and lead times.

Healthcare:

The medical field has already witnessed the transformative power of 3D printing. Prosthetics are becoming more advanced and accessible, enabling individuals with limb loss to regain mobility and independence. Bioprinting, the process of creating living tissue structures, holds the potential to revolutionize organ transplantation by providing patients with bespoke, 3D-printed organs. This could alleviate the organ shortage crisis and increase the success rates of surgeries.

Construction:

In the construction industry, 3D printing is expected to play a significant role in addressing housing affordability and sustainability. Companies like Winsun have already demonstrated the ability to 3D print houses using recycled materials at a fraction of the cost of traditional construction methods. As the technology advances, we may see entire neighborhoods printed with customized fixtures and efficient designs, reducing waste and construction time.

Sustainability and Automotive:

3D printing is also paving the way for sustainable practices in various sectors. In aviation, the use of recycled materials combined with 3D printing techniques is emerging, making aircraft manufacturing more environmentally friendly. Additionally, the automotive industry is utilizing 3D printing to create flexible parts and customized end-use components, enhancing vehicle performance and design.

| Sector | Future Implications of 3D Printing |

|---|---|

| Manufacturing | Shift towards digital warehouses and local production |

| Healthcare | Advanced prosthetics, bioprinting of organs |

| Construction | 3D-printed houses, customized fixtures |

| Sustainability and Automotive | Use of recycled materials, flexible parts, customized components |

The future of 3D printing is bright and filled with numerous possibilities. As the technology continues to evolve, we can expect to see even greater advancements and applications in different sectors. Whether it’s transforming manufacturing processes, revolutionizing healthcare, addressing housing challenges, or promoting sustainability, 3D printing is set to shape the future in profound ways.

Conclusion

As we conclude our exploration of 3D printing technology and its future implications, it is clear that this innovative technology has the potential to reshape various industries. From manufacturing to healthcare, construction, and sustainability, 3D printing is revolutionizing the way we live and work.

With advancements in 3D printing, companies can now manufacture products locally, reducing outsourcing and potentially creating economic restructuring. Inventors and creatives can turn their ideas into reality more easily, resulting in a wide range of 3D-printed products that were once unimaginable.

In the medical field, 3D printing is already making a significant impact. From creating prosthetics at a lower cost to bioprinting organs and 3D-printed pills, this technology is improving accessibility to life-changing medical solutions. Furthermore, the construction industry is benefiting from 3D printing by addressing housing affordability issues and using recycled materials to save costs and contribute to environmental sustainability.

Looking ahead, the future of 3D printing holds tremendous possibilities. From the creation of “digital warehouses” in manufacturing to more advanced prosthetics and bioprinting in healthcare, the potential for innovation is vast. Customized fixtures, sustainable practices, and even 3D-printed components for the automotive industry are on the horizon.

As technology continues to improve and become more accessible, we can expect to witness even more groundbreaking advancements in the world of 3D printing. The future is bright for this transformative technology, and its impact on various sectors will continue to shape our future.

FAQ

How is 3D printing impacting the manufacturing industry?

3D printing allows companies to manufacture products locally and reduces the need for outsourcing. It also makes it easier for inventors and creatives to turn their ideas into realities.

How is 3D printing being used in the medical field?

3D printing is being used to create prosthetics at a lower cost, making it more accessible for everyone. It is also being used for bioprinting, which has the potential to revolutionize surgery by creating 3D-printed organs.

What is the potential of 3D printing in the construction industry?

3D printing can significantly reduce construction costs by using recycled materials and speeding up the construction process. Companies like Winsun are already using 3D printing technology to build houses at a fraction of the cost of traditional methods.

What does the future hold for 3D printing?

The future of 3D printing holds numerous possibilities, including the creation of “digital warehouses” for printable parts and tools in manufacturing, advancements in bioprinting for creating organs in healthcare, and increased use of 3D printing in construction and sustainability efforts.

How has 3D printing already transformed industries?

3D printing has already made significant advancements in various industries, allowing for cost-effective experimentation, rapid prototyping, and the creation of complex products such as prosthetics, dental assistants, and replacement joints. It has also enabled innovations in construction, space tools, garments, and more.

What sectors will be impacted by 3D printing in the future?

The future of 3D printing holds tremendous potential in various sectors, including manufacturing, healthcare, construction, sustainability, and automotive. Each sector can benefit from the cost-effective and customizable nature of 3D printing technology.