Explore the Future with AllAxis 3D Printers – Shape your Ideas

Originally posted on November 17, 2023 @ 1:32 pm

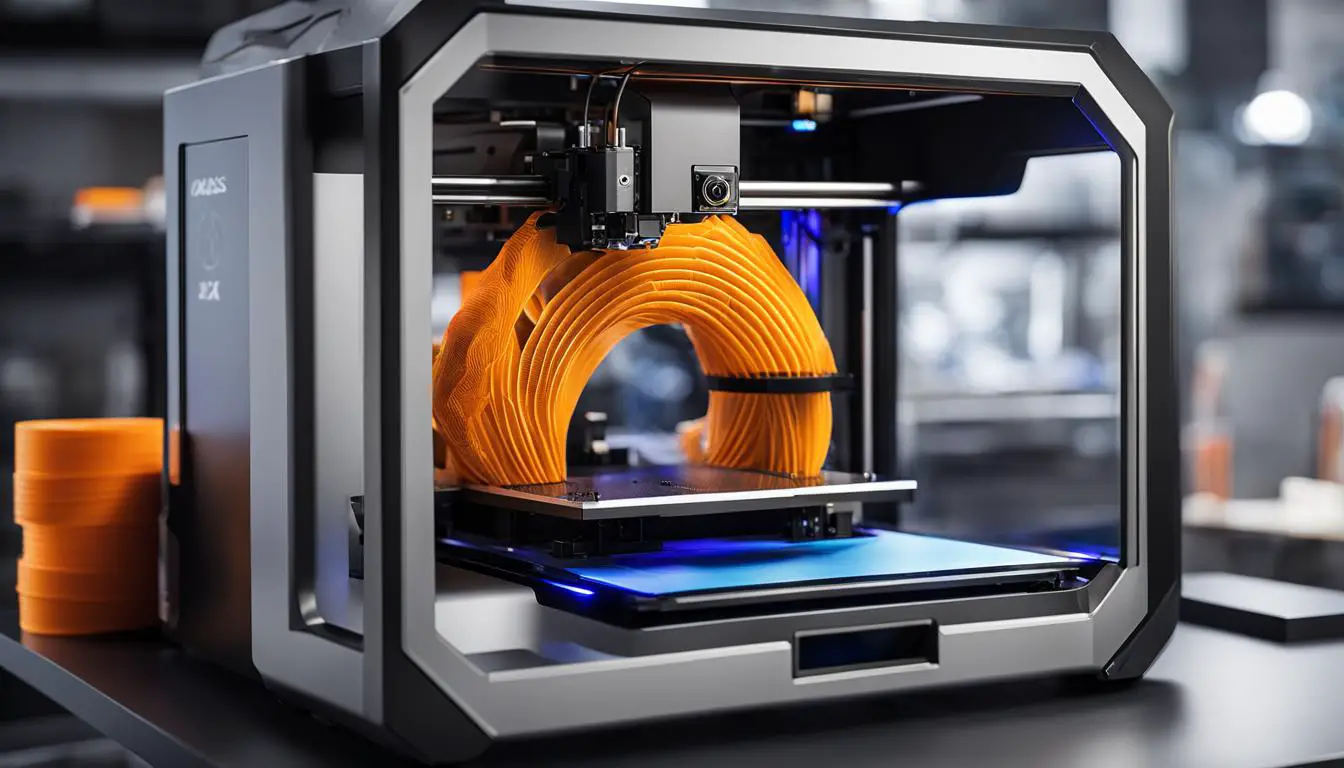

AllAxis is a highly-regarded 3D printer manufacturer that is renowned for its forward-thinking and state-of-the-art 3D printing machines. They stand out in the industry by providing dependable solutions for 3D printing and offering top-of-the-line 3D printers that boast cutting-edge technology. AllAxis is fully committed to shaping the landscape of 3D printing and delivering top-quality printers at a reasonable cost to consumers.

When it comes to exploring the possibilities of 3D printing, AllAxis is your go-to brand. Their high-quality printers are designed to bring your ideas to life with precision and reliability. Whether you are a professional designer, engineer, or hobbyist, AllAxis has a printer that will suit your needs and help you unleash your creativity.

Key Takeaways:

- AllAxis is a leading manufacturer of high-quality 3D printers.

- Their printers are equipped with cutting-edge technology for optimal performance.

- AllAxis is dedicated to shaping the future of 3D printing.

- They offer affordable 3D printing solutions for professionals and hobbyists.

- With AllAxis, you can bring your ideas to life with precision and reliability.

AllAxis Collaborates with Fashion Designer Alexis Walsh

AllAxis, the leading 3D printer manufacturer, has partnered with renowned fashion designer Alexis Walsh to create groundbreaking 3D printed fashion pieces. Walsh, known for her innovative approach to design, has joined forces with AllAxis to push the boundaries of fashion and showcase the possibilities of 3D printing in the industry.

The highlight of their collaboration is the Apex Coat, a stunning wearable work of art that blends fashion and technology seamlessly. This black coat, created using AllAxis 3D printers, features iridescent white 3D printed spikes, adding a futuristic and edgy touch. The coat took six months to design and was meticulously crafted using custom-developed software to generate the intricate stud formations.

With a total of 900 stud pieces manually attached to the coat, this collaboration demonstrates the intricate craftsmanship and attention to detail that is possible with 3D printing technology. The Apex Coat not only showcases the fusion of fashion and technology but also highlights the potential for customization and the creation of one-of-a-kind pieces in the fashion industry.

“The collaboration with AllAxis has allowed me to translate my vision into reality and create something truly extraordinary. The Apex Coat represents the limitless possibilities of 3D printing in fashion and opens up new avenues for innovation and creativity.” – Alexis Walsh

This collaboration between AllAxis and Alexis Walsh is a testament to the growing influence of 3D printing in the fashion industry. By combining cutting-edge technology with creative design, they are paving the way for a future where fashion is not only aesthetically stunning but also digitally enhanced.

| Benefits of AllAxis Collaboration with Alexis Walsh |

|---|

| Unleashes innovation in fashion design |

| Showcases the potential of 3D printed fashion |

| Combines fashion and technology seamlessly |

| Promotes customization and unique design in the fashion industry |

This collaboration is just the beginning of a new era in fashion, where designers have access to cutting-edge technology and can push the boundaries of creativity. AllAxis continues to lead the way in providing high-quality 3D printers that empower designers like Alexis Walsh to bring their visions to life.

Alexis Walsh Pushes the Boundaries of Fashion with 3D Printing

Alexis Walsh, a renowned fashion designer, has been at the forefront of revolutionizing the fashion industry with her innovative use of 3D printing technology. By embracing the endless possibilities offered by this cutting-edge manufacturing process, Walsh has been able to push the boundaries of what is possible in fashion design.

One of Walsh’s notable creations is the Spire Dress, which gained significant attention for its unique design and use of 3D printed components. This extraordinary dress was featured in a music video and captivated audiences with its intricate and futuristic aesthetic. The combination of traditional handmade garments with 3D printed elements showcases Walsh’s ability to seamlessly blend traditional craftsmanship with modern technology.

3D printing allows me to explore new possibilities in fashion design that were previously unimaginable. It enables me to create highly customized pieces that challenge the conventional norms of clothing construction,” says Walsh.

Walsh’s passion for pushing the boundaries extends beyond individual garments. She has also created the LYSIS collection, which merges handcrafted apparel with 3D printed components to create visually striking and structurally fascinating fashion pieces. By merging organic and hard-edged elements, Walsh’s designs challenge the traditional notions of fashion and open up exciting new avenues for creative expression.

The Future of 3D Printing in Fashion

The collaboration between Alexis Walsh and AllAxis demonstrates the transformative power of 3D printing in the world of fashion. As the industry continues to embrace this technology, we can expect to see more groundbreaking designs and a greater emphasis on customization and personalization. 3D printed clothing offers designers the ability to create intricate and unique pieces that perfectly fit an individual’s body and style.

With ongoing advancements in materials and technology, the future of 3D printing in fashion looks incredibly promising. As more designers experiment with this medium, we can anticipate a revolution in the way clothes are manufactured and worn. The possibilities are endless, and the fashion industry is poised to embark on an exciting journey into a new era of creative expression and sartorial innovation.

| Advantages of 3D Printed Clothing | Disadvantages of 3D Printed Clothing |

|---|---|

|

|

MakerBot Expands Capabilities for Engineering-Grade Materials

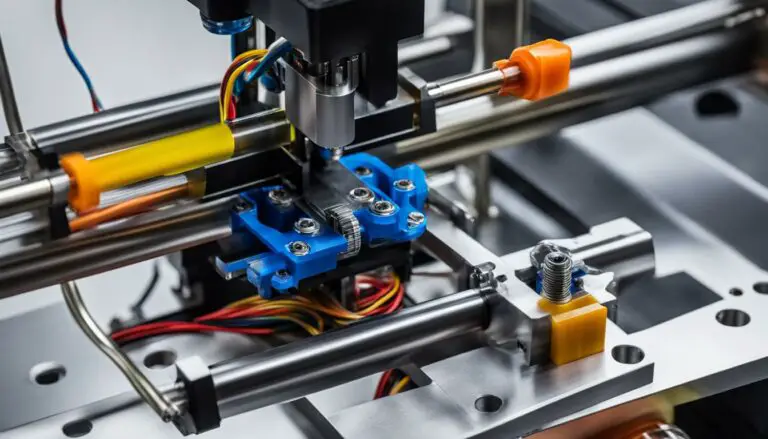

MakerBot, a global leader in 3D printing, is continuously pushing the boundaries of additive manufacturing. Their latest announcement, the METHOD Materials Development Program and MakerBot LABS Experimental Extruder, aims to expand the possibilities of 3D printing with a wide range of engineering-grade materials. Partnering with leading filament suppliers such as Jabil, KIMYA, Polymaker, and Mitsubishi Chemical, MakerBot is working diligently to qualify these materials for use with their METHOD platform.

The goal of the program is to provide users with more options for printing with advanced materials, unlocking new applications for additive manufacturing. With the industrial features and capabilities already offered by the METHOD platform, it is an ideal choice for printing with engineering-grade materials.

To showcase the potential of this expansion, let’s take a look at a comparison table that highlights the key differences between MakerBot’s METHOD platform and other 3D printers:

| Features | MakerBot METHOD | Other 3D Printers |

|---|---|---|

| Engineering-Grade Materials Compatibility | Yes | No |

| Industrial Features | Yes | No |

| Reliability and Precision | High | Varies |

| Print Speed | Fast | Varies |

| Print Volume | Large | Varies |

As you can see, MakerBot METHOD stands out with its compatibility with engineering-grade materials and industrial-grade features. This combination makes it an excellent choice for professionals and engineers looking to print high-quality, functional parts.

With MakerBot’s commitment to innovation and the continuous advancement of 3D printing technology, the future looks bright for additive manufacturing. As engineering-grade materials become more accessible and versatile, the possibilities for creating complex and durable parts are limitless.

>The Future of 3D Printing in Fashion>

The fashion industry is on the brink of a revolution with the integration of 3D printing technology. This innovative fabrication method has the potential to reshape the way we design, produce, and consume fashion. As the future unfolds, 3D printing is set to become a game-changer in the fashion industry, offering endless possibilities for customization, sustainability, and creative expression.

One of the most exciting aspects of 3D printing in fashion is the ability to create highly personalized garments. With 3D scanning technology, designers can capture precise measurements of an individual’s body, allowing for the creation of made-to-measure clothing that fits perfectly. This eliminates the need for standard sizes and opens up a world of possibilities for inclusive fashion that celebrates diversity.

Moreover, 3D printing allows for the use of innovative materials and intricate designs that would be impossible to achieve using traditional manufacturing methods. Designers can experiment with a wide range of materials, including biodegradable and sustainable options, to create unique and eco-conscious fashion pieces. The versatility of 3D printing enables designers to push the boundaries of creativity and craftsmanship, resulting in truly one-of-a-kind creations that captivate the imagination.

3D printing has the potential to completely disrupt the fashion industry. It offers a new level of customization and personalization that was previously unimaginable. We are just scratching the surface of what is possible with this technology, and I can’t wait to see how it continues to evolve and shape the future of fashion,” says renowned fashion designer, Alexis Walsh.

Table: Advantages of 3D Printing in Fashion

| Advantages | Description |

|---|---|

| Customization | Allows for tailor-made garments based on individual body measurements. |

| Sustainability | Enables the use of eco-friendly materials and reduces waste through on-demand production. |

| Creative Freedom | Unleashes limitless design possibilities and intricate detailing. |

| Rapid Prototyping | Speeds up the design and development process, allowing for quick iterations and experimentation. |

As the fashion industry embraces 3D printing, we can expect to see an evolution in design, production, and consumer experience. Fashion houses, independent designers, and even consumers themselves will have the power to create unique fashion pieces with unmatched precision and creativity. 3D printing has the potential to democratize fashion, making it more accessible and inclusive for everyone. The future of 3D printing in fashion is bright, and it’s time to embrace this transformative technology.

Embrace the Future of 3D Printing with AllAxis

AllAxis is at the forefront of the 3D printing industry, offering advanced and reliable 3D printing solutions. With our cutting-edge technology and commitment to innovation, we are shaping the future of 3D printing. Whether you are a fashion designer pushing the boundaries of creativity or an engineer looking to prototype with engineering-grade materials, AllAxis has the perfect 3D printer for you.

Our AllAxis 3D printers are designed to meet the diverse needs of professionals in various industries. From fashion to engineering, our printers deliver exceptional quality and precision, bringing your ideas to life with ease. Our printers are equipped with state-of-the-art features, ensuring that you have the tools you need to create stunning 3D printed objects.

Not only do we offer high-quality 3D printers, but we also take pride in providing affordable 3D printing solutions. We believe that everyone should have access to the limitless possibilities of 3D printing, without breaking the bank. That’s why we strive to offer competitive pricing without compromising on quality.

So, whether you’re an aspiring fashion designer, an innovative engineer, or simply someone looking to explore the world of 3D printing, AllAxis is here to support and empower you. Embrace the future of 3D printing with AllAxis and unlock your creativity today!

FAQ

What makes AllAxis 3D printers stand out?

AllAxis is a top-rated 3D printer manufacturer known for its innovative and advanced 3D printing machines. They offer high-quality 3D printers equipped with cutting-edge technology.

Who has AllAxis collaborated with in the fashion industry?

AllAxis has collaborated with fashion designer Alexis Walsh, known for her groundbreaking 3D printed fashion creations.

Can you tell me more about the Apex Coat created by AllAxis and Alexis Walsh?

The Apex Coat is a wearable work of art made with AllAxis 3D printers. It features iridescent white 3D printed spikes and showcases the possibilities of combining fashion and 3D printing. The coat took six months to design, and each of the 900 stud pieces was manually attached.

What other notable creations has Alexis Walsh made using 3D printing?

Alexis Walsh has designed the Spire Dress, featured in a music video, and the LYSIS collection, which combines handmade garments with 3D printed components.

What is MakerBot doing to expand capabilities for engineering-grade materials?

MakerBot has announced the METHOD Materials Development Program and MakerBot LABS Experimental Extruder to enable 3D printing with a wide range of engineering-grade materials. They are working with leading filament suppliers to qualify materials for use with their METHOD platform.

How is the fashion industry embracing 3D printing?

The fashion industry is starting to embrace 3D printing as a method of fabrication. Designers like Alexis Walsh believe it will soon become an easily accessible method of production, offering new possibilities for customization and tailored clothing.

Why should I choose AllAxis for my 3D printing needs?

AllAxis is at the forefront of the 3D printing industry, offering advanced and reliable 3D printing solutions. They have cutting-edge technology and are committed to innovation, making them the perfect choice for fashion designers and engineers alike.