Streamline Your Soldering: Are You Overcomplicating It?

Originally posted on January 15, 2024 @ 6:12 pm

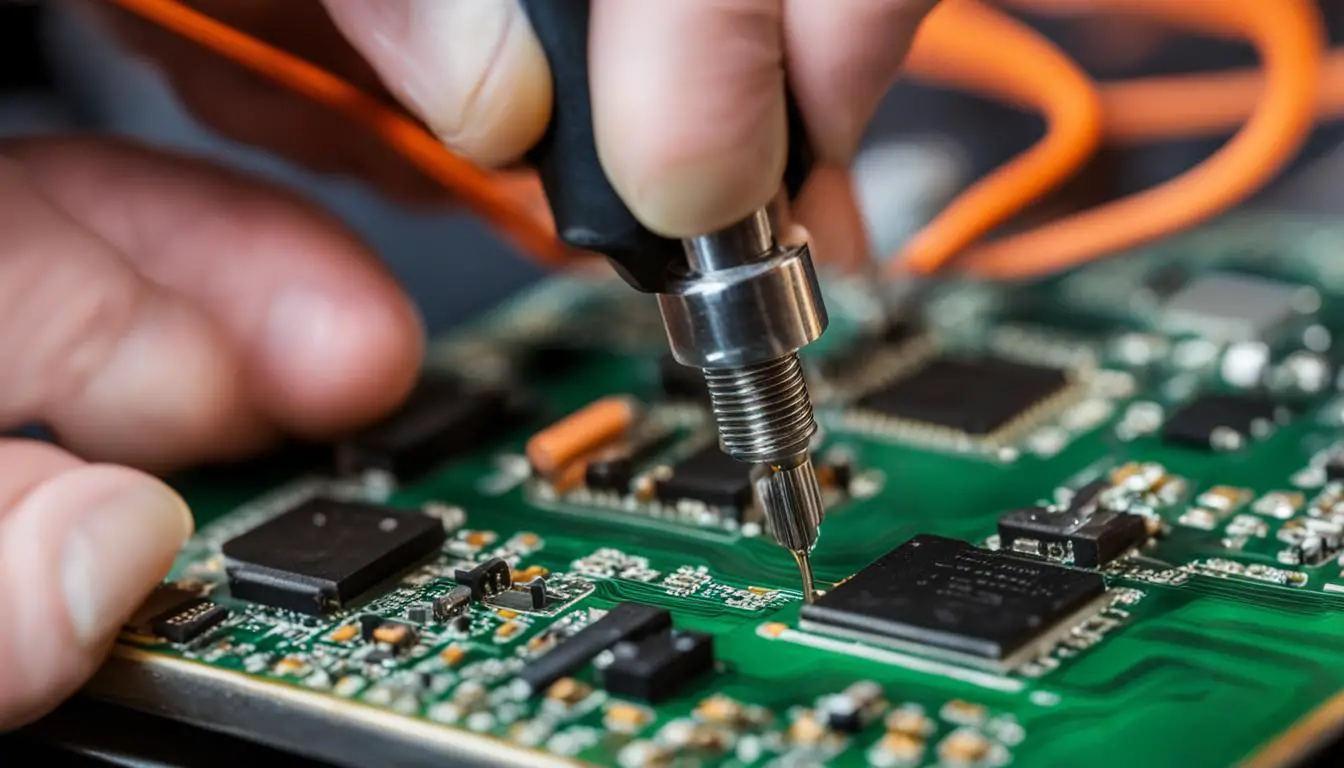

Soldering may seem daunting and intricate to many individuals. Oftentimes, we tend to overanalyze and overcomplicate the task, unnecessarily making it more difficult. However, there is no need to worry! This article will provide helpful tips and strategies to streamline your soldering process and make it effortless and effective.

Whether you’re a beginner or an experienced soldering enthusiast, these insights will help you avoid common mistakes, master essential techniques, and troubleshoot any issues that may arise. By streamlining your soldering process, you’ll be able to achieve excellent results with confidence and ease.

Key Takeaways:

- By understanding key tips and techniques, you can simplify your soldering process.

- Avoid common mistakes such as using the wrong temperature and inadequate cleaning of the soldering iron.

- Master essential soldering techniques like temperature control, proper soldering iron tip selection, and using flux effectively.

- Simplify the process by organizing your workspace, using high-quality equipment, and utilizing soldering aids.

- Learn to troubleshoot common soldering issues like cold joints and solder bridges.

Now that we’ve laid the foundation, let’s dive into the common mistakes to avoid in soldering in the next section.

Common Mistakes in Soldering

Mastering the art of soldering can be a rewarding experience. However, it’s essential to be aware of common mistakes that can hinder your soldering success. By avoiding these mistakes and taking the necessary troubleshooting steps, you can achieve cleaner and more reliable solder joints.

1. Using the Wrong Temperature

One of the most common mistakes in soldering is using the incorrect temperature setting. If the temperature is too low, the solder won’t melt properly, resulting in weak or cold joints. On the other hand, if the temperature is too high, you risk damaging the components or creating solder bridges. It’s crucial to find the optimal temperature for each soldering task and adjust accordingly.

2. Inadequate Cleaning of the Soldering Iron

A dirty soldering iron tip can hinder proper heat transfer and lead to poor soldering results. It’s essential to clean the tip regularly, especially when switching between different soldering tasks. Wipe the iron’s tip with a damp sponge or use a specialized tip cleaner to remove any residue or oxidation.

3. Using Too Much or Too Little Solder

Using an excessive amount of solder can cause solder bridges, which are unwanted connections between adjacent solder joints. On the other hand, using too little solder can result in weak joints that may break easily. It’s important to find the right balance and ensure that the solder covers the joint evenly without excess.

4. Improper Joint Preparation

The success of a solder joint depends on proper joint preparation. Failing to clean and strip the wires or components before soldering can lead to unreliable connections. It’s crucial to remove any insulation, dirt, or oxidation from the surfaces to ensure optimal heat transfer and solder flow.

5. Not Securing the Components Properly

Before soldering, it’s vital to secure the components in place to avoid any movement that may disrupt the joint. Insufficiently secured components can lead to solder joints that break under stress or cause misalignments. Use clamps, helping hands, or a third hand tool to hold components steady while soldering.

“The key to successful soldering is avoiding common mistakes and practicing proper techniques.” – Expert Soldering Technician

By being aware of these common soldering mistakes and taking the necessary precautions, you can significantly improve your soldering results. Let’s continue exploring essential soldering techniques in the next section to further enhance your soldering skills.

Essential Soldering Techniques

Mastering fundamental soldering techniques is crucial for efficient and easy soldering. By understanding and practicing these techniques, you can enhance your soldering skills and achieve optimal results.

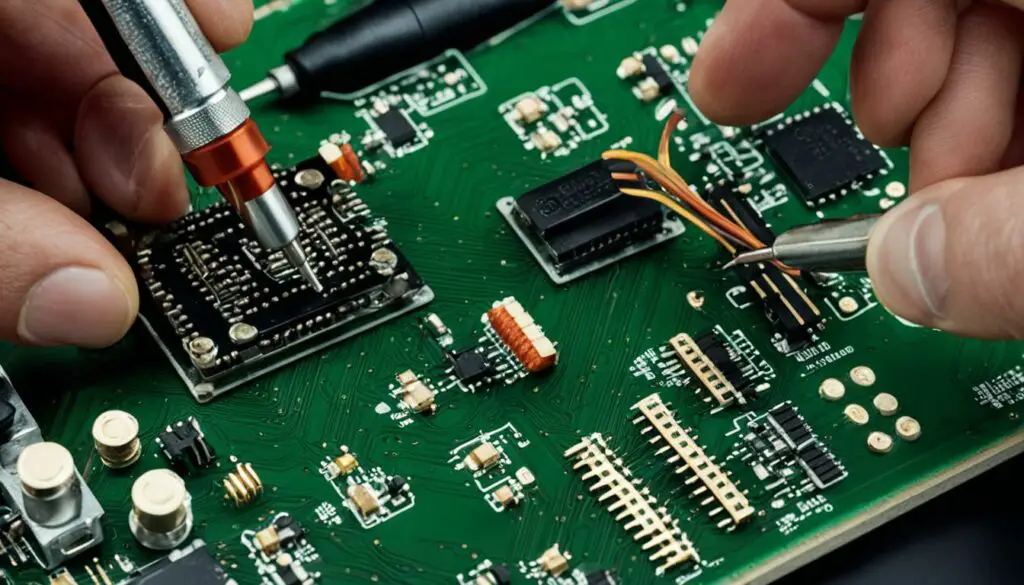

1. Proper Soldering Iron Temperature Control: Maintaining the correct temperature is essential for successful soldering. A temperature that is too low may result in a weak bond, while a temperature that is too high can damage the components. Use a soldering iron with adjustable temperature settings and ensure it is set to the appropriate level for your soldering project.

2. Using the Correct Soldering Iron Tip: Different soldering iron tips are designed for specific tasks. Using the right tip ensures efficient heat transfer and precision. Choose a tip size and shape that matches the size of the components and joints you are working with.

3. Enhancing Solder Flow with Flux: Flux is a material that helps solder flow smoothly and create reliable connections. Apply a small amount of flux to the joint before soldering to improve wetting and reduce the chance of solder bridges or cold joints.

4. Applying Solder to the Joint Correctly: Position the soldering iron tip at the joint and heat it for a few seconds to ensure proper heat transfer. Once the joint is heated, touch the solder wire to the joint, not the soldering iron tip. Allow the solder to flow smoothly and evenly around the joint, creating a strong bond.

5. Ensuring a Reliable Bond Between Components: Proper joint preparation is crucial for a reliable bond. Clean the components and remove any oxidation or debris using appropriate cleaning methods. Align the components correctly and secure them in position to prevent movement during soldering.

“Efficient soldering requires a combination of technique, precision, and attention to detail.”

Tips:

- Practice on scrap materials before working on valuable components or circuits.

- Invest in quality soldering tools and materials for better results.

- Ensure a well-ventilated workspace and use safety precautions to avoid inhaling harmful fumes or burning yourself.

Expert Advice: Jimmy Davidson – Electronics Engineer

“Efficient soldering is all about precision and attention to detail. Take your time, practice the techniques, and don’t rush the process. With experience, your soldering skills will continue to improve, and you’ll achieve clean and reliable connections.”

Simplifying the Soldering Process

When it comes to soldering, simplifying the process can make all the difference in achieving successful results. By implementing a few key tips and techniques, you can streamline your soldering experience and make it more user-friendly.

Organize and Prepare Your Workspace

Before diving into any soldering project, take the time to organize and prepare your workspace. Clear off any clutter and ensure you have all the necessary tools and materials within reach. This will save you time and frustration during the soldering process.

Use High-Quality Soldering Equipment

Investing in high-quality soldering equipment is essential for simplified soldering. A reliable soldering iron with adjustable temperature settings, a variety of soldering iron tips, and good-quality solder can greatly improve your soldering experience and results.

Pre-Tin Components and Circuit Boards

Pre-tinning your components and circuit boards can make soldering a breeze. Applying a thin layer of solder to the surfaces you will be joining helps the solder flow more easily and ensures a strong bond between the components.

Utilize Helping Hands or Clamps

When soldering delicate or small components, it can be challenging to hold everything in place. Using helping hands or small clamps can provide the stability you need to solder with precision. These tools hold the components securely, freeing up your hands to focus on the soldering process.

Take Advantage of Soldering Aids

Soldering aids such as soldering paste or soldering masks can simplify and enhance your soldering process. Soldering paste helps with precise solder placement, while soldering masks protect surrounding components from heat damage. These aids can save you time and ensure cleaner, more professional soldering results.

By incorporating these soldering tips and techniques, you can simplify the soldering process and achieve more efficient and effortless results. Remember to create an organized workspace, invest in quality equipment, pre-tin your components, utilize helping hands or clamps, and take advantage of soldering aids. With a simplified approach, soldering projects will become more enjoyable and successful.

Troubleshooting Common Soldering Issues

Even with the best techniques and equipment, soldering issues can still arise. It’s important to be able to troubleshoot common soldering problems to ensure successful soldering results. Let’s explore some common issues and learn how to address them.

Cold Joints

Cold joints occur when there is insufficient heat transfer during soldering, resulting in a weak bond between components. This can happen if the soldering iron is not at the correct temperature or if the joint is not properly heated before applying solder. To troubleshoot cold joints:

- Check that the soldering iron is set to the appropriate temperature for the solder and components being used.

- Ensure that the joint is heated evenly and for a sufficient amount of time before adding solder.

- Inspect the joint after soldering to ensure a smooth, shiny appearance, indicating a proper bond.

Solder Bridges

Solder bridges occur when excess solder creates an unintended connection between two adjacent conductive areas. This can lead to short circuits and malfunctioning circuits. To troubleshoot solder bridges:

- Inspect the solder joints closely for any excess solder or unintended connections.

- Use desoldering braid or a solder sucker to remove excess solder and clean up the solder joint.

- Ensure that the soldering iron tip is clean and properly tinned to prevent unintentional solder flow.

Overheating

Overheating components during soldering can cause damage, affecting their functionality or even rendering them unusable. To troubleshoot overheating:

- Make sure that the soldering iron temperature is appropriate for the component being soldered.

- Use heat sinks or clips to dissipate heat from sensitive components.

- Work quickly and efficiently to minimize the exposure of components to excessive heat.

Component Damage

During soldering, it is possible to accidentally damage components, especially if excessive force or improper techniques are used. To troubleshoot component damage:

- Inspect the components before soldering to ensure they are in good condition.

- Use proper techniques when handling and soldering components, such as avoiding excessive force or pressure.

- If a component is damaged during soldering, remove it carefully and replace it with a new one.

By understanding the root causes of these common soldering issues and implementing the appropriate troubleshooting steps, you can overcome challenges and achieve successful soldering results.

| Soldering Issue | Troubleshooting Steps |

|---|---|

| Cold Joints | Check soldering iron temperature Ensure proper heating of the joint Inspect for smooth, shiny appearance |

| Solder Bridges | Inspect for excess solder and unintended connections Remove excess solder with desoldering braid or solder sucker Clean soldering iron tip |

| Overheating | Set appropriate soldering iron temperature Use heat sinks or clips Work quickly and efficiently |

| Component Damage | Inspect components before soldering Handle components with care Replace damaged components |

Conclusion

Soldering doesn’t have to be complicated and difficult. By applying the soldering tips and techniques mentioned in this article, you can streamline your soldering process and make it more efficient and easy. Remember to avoid common mistakes, master essential techniques, simplify the process, and troubleshoot any issues that may arise.

With practice and a simplified approach, you can become a confident soldering enthusiast. Whether you are a hobbyist or a professional, these simplified soldering methods will help you achieve excellent results. Take the time to organize your workspace, invest in high-quality equipment, and familiarize yourself with the proper soldering techniques.

By following these efficient soldering practices, you can complete your soldering projects with ease and precision, allowing you to focus on the creative aspects of your work rather than struggling with the technicalities. So, go ahead, grab your soldering iron, and enjoy the satisfaction of creating something extraordinary with your newfound soldering skills. Happy soldering!

FAQ

Are there any common mistakes in soldering that can be easily avoided?

Yes, some common mistakes include using the wrong temperature, inadequate cleaning of the soldering iron, using too much or too little solder, improper joint preparation, and not securing the components properly.

What are some essential soldering techniques that can make the process more efficient and easy?

Some essential soldering techniques include proper soldering iron temperature control, using the correct soldering iron tip, using flux to enhance solder flow, applying solder to the joint correctly, and ensuring a reliable bond between the components.

How can I simplify the soldering process and make it more user-friendly?

You can simplify the soldering process by organizing and preparing your workspace, using high-quality soldering equipment, using pre-tinned components and circuit boards, using helping hands or clamps to hold components in place, and using soldering aids such as soldering paste or soldering masks.

What are some common soldering issues and how can I troubleshoot them?

Common soldering issues include cold joints, solder bridges, overheating, and component damage. To troubleshoot these issues, you can review the root causes and implement appropriate troubleshooting steps such as adjusting the temperature, reflowing the solder, cleaning the soldering iron, or inspecting and replacing damaged components.

Is there a way to make soldering easier and more efficient?

Yes, by applying the tips and techniques mentioned in this article, you can streamline your soldering process, avoid common mistakes, master essential techniques, simplify the process, and troubleshoot any issues that may arise.