Shapeways 3D Printing Vs Others: A Detailed Comparison

Originally posted on December 16, 2023 @ 5:41 am

This piece will explore the realm of 3D printing and assess the leading 3D Printing service by Shapeways in comparison to others currently available. Regardless of your purpose of seeking an online 3D printing service, investigating the 3D printing marketplace, or pursuing cost-effective and expert custom 3D printing solutions, we have you covered.

Shapeways 3D Printing is renowned for its versatility, providing a wide range of materials and finishes to cater to various industries and applications. In our analysis, we’ll explore how Shapeways stacks up against other 3D printing services like Protomold and highlight its unique features and advantages. From the cost comparison to the versatility of materials and finishes, we’ll cover it all.

Key Takeaways:

- Shapeways offers a cost-effective solution for custom 3D printing.

- Protomold may be more cost-effective for larger quantities.

- Shapeways provides a wide range of materials and finishes for versatile designs.

- 3D printing allows for fast iteration and customization.

- Shapeways Marketplace showcases innovative 3D printed products.

The Cost Comparison of Shapeways 3D Printing and Protomold

A blog post by 3sourceful compared the cost of manufacturing two different parts using Shapeways 3D printing and Protomold, an injection molding service. The cost analysis showed that for smaller parts, 3D printing was more cost-effective at lower quantities, while Protomold became cheaper for larger quantities due to the cost of 3D printing materials. However, the comparison did not consider factors such as upfront investment, inventory management, and the ability to customize and iterate designs, which are advantages of 3D printing over injection molding.

In the comparison, it was found that for small quantities, 3D printing with Shapeways was more economical due to the lower setup and tooling costs compared to injection molding with Protomold. The cost per part decreased as the quantity increased for injection molding, making it a more viable option for large-scale production. However, it’s important to note that these results only take into account the direct costs of production and do not consider other factors that can influence the overall cost-effectiveness.

While injection molding may be more cost-effective at higher volumes, 3D printing offers unique advantages in terms of customization and design flexibility. Shapeways allows designers to easily iterate and modify their designs without the need for costly tooling changes. This ability to make quick design iterations can significantly reduce development time and cost, especially during the prototyping phase. Furthermore, with 3D printing, manufacturers can create complex and intricate designs that would be challenging to achieve with traditional manufacturing methods like injection molding.

| Cost Comparison | Shapeways 3D Printing | Protomold Injection Molding |

|---|---|---|

| Setup Costs | Low | High |

| Tooling Costs | None | High |

| Cost per Part | Depends on quantity; higher for small quantities | Depends on quantity; lower for large quantities |

| Customization | Highly customizable | Less customizable |

| Design Iteration | Quick and cost-effective | Costly and time-consuming |

In conclusion, while the cost comparison between Shapeways 3D printing and Protomold injection molding shows that each method has its advantages depending on the quantity and complexity of the parts, it is essential to consider the specific needs and requirements of your project. 3D printing with Shapeways provides cost-effective solutions for smaller quantities and offers the flexibility to customize and iterate designs. On the other hand, Protomold injection molding can be more cost-effective for larger quantities, but lacks the same level of design flexibility. It ultimately comes down to the specific production needs and priorities of each project.

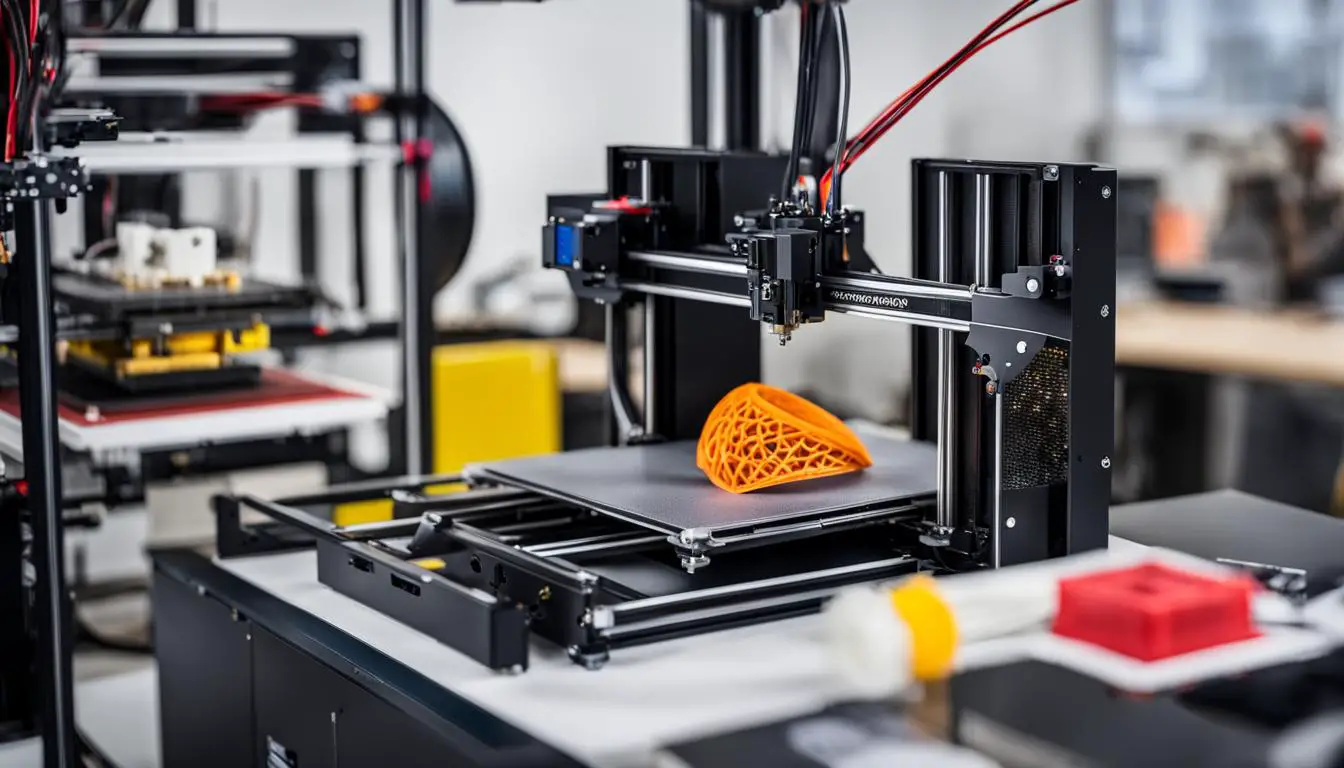

The Versatility of Shapeways 3D Printing

When it comes to 3D printing, Shapeways stands out for its exceptional versatility. With a wide range of materials and finishes, designers have the freedom to create customized and high-quality 3D printed products. Whether you’re looking to produce vintage automotive parts, miniature components, or fine jewelry, Shapeways has the options to bring your vision to life.

One of the key advantages of Shapeways is its ability to offer fast iteration and customization options. Unlike traditional manufacturing methods like injection molding, where modifications can be costly and time-consuming, Shapeways allows designers to easily modify and optimize their designs without any additional cost or delay. This flexibility empowers designers to push the boundaries of their creativity and continuously improve their products.

“Shapeways has revolutionized the way I approach product development. The ability to quickly iterate and customize designs without breaking the bank has been a game-changer for my business.” – Jane, jewelry designer

In addition to its versatility, Shapeways also offers a seamless and user-friendly experience. With their intuitive online platform, uploading and ordering 3D prints has never been easier. Whether you’re a seasoned designer or new to the world of 3D printing, Shapeways provides the tools and support you need to bring your ideas to life.

Materials and Finishes

Shapeways boasts an extensive library of over 90 materials and finishes, catering to a wide range of applications and industries. From durable plastics to precious metals, designers have access to a diverse selection of materials that meet their specific needs. Whether you’re looking for strength, flexibility, or a specific aesthetic, Shapeways has you covered.

Some of the available materials include:

- Strong & Flexible Plastic

- Metallic Plastic

- Silver

- Brass

- Bronze

- Gold

- Premium Metals

Each material comes with its own set of unique properties, allowing designers to choose the perfect material to bring their designs to life. Paired with a variety of finishes such as polished, matte, and antique, designers can achieve the desired look and feel for their 3D printed products.

| Material | Properties | Applications |

|---|---|---|

| Strong & Flexible Plastic | Durable, lightweight, and flexible | Prototypes, consumer products, fashion accessories |

| Metallic Plastic | Metal-like appearance and feel | Jewelry, consumer products, art |

| Silver | Premium precious metal, high-quality finish | Jewelry, custom creations |

| Brass | Durable and corrosion-resistant | Decorative items, hardware |

| Bronze | Warm and natural appearance | Sculptures, art, jewelry |

| Gold | Luxurious and timeless | Jewelry, custom creations |

| Premium Metals | High-quality precious metals like platinum and palladium | Specialized jewelry and custom designs |

With such a diverse range of materials and finishes at your disposal, Shapeways empowers designers to create truly unique and personalized 3D printed products. Whether you’re a hobbyist or a professional, Shapeways is the go-to platform for turning your ideas into reality.

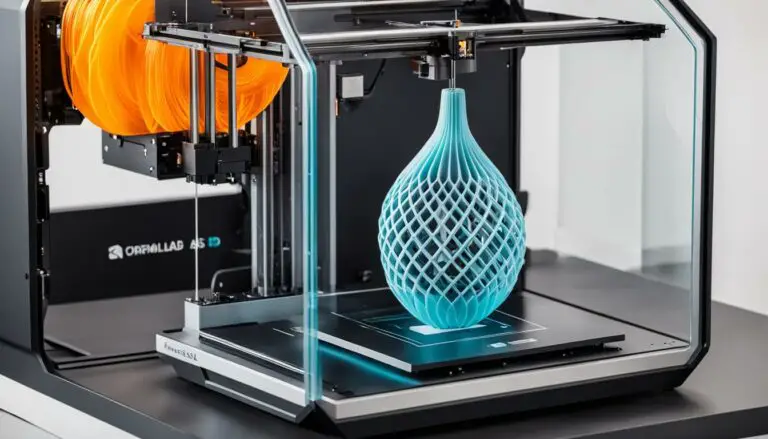

Understanding Additive Manufacturing and 3D Printing

When discussing the world of 3D printing, two terms often come up: additive manufacturing and 3D printing. While they are used interchangeably, they have distinct connotations. Additive manufacturing refers to the process of building a 3D product layer by layer from a CAD file, while 3D printing specifically denotes the use of a 3D printer to create the structure.

Shapeways, a leading online 3D printing service, offers a variety of 3D printing technologies and over 90 materials and finishes. This wide range of options caters to both traditional manufacturing and industrial applications, providing designers and manufacturers with the flexibility to choose the most suitable technology and material for their specific needs.

Understanding the different designations and technologies in additive manufacturing is crucial for designers and manufacturers alike. Shapeways empowers them with the knowledge and tools to bring their ideas to life, whether it’s through 3D printing or other additive manufacturing processes. With the ability to create intricate designs and access a diverse range of materials, the possibilities for innovation are limitless.

With Shapeways, designers and manufacturers can stay at the forefront of the additive manufacturing revolution, utilizing advanced technology and materials to create high-quality products.

The Advantages of Additive Manufacturing

Additive manufacturing, including 3D printing, offers several advantages over traditional manufacturing methods. Firstly, it enables designers to create complex geometries and intricate designs that would be challenging or impossible to produce using conventional processes.

Secondly, additive manufacturing allows for rapid prototyping and fast iteration. Designers can easily modify and optimize their designs without incurring significant costs or delays. This flexibility accelerates the product development cycle, giving designers a competitive edge in bringing their ideas to market.

Additionally, additive manufacturing reduces material waste compared to traditional manufacturing, where excess material is often generated through subtractive processes. This makes it a more sustainable and environmentally friendly option.

The Materials and Technology Behind Additive Manufacturing

Shapeways offers a vast selection of materials and finishes, catering to various applications and industries. From high-performance plastics to metals, ceramics, and even food-safe materials, the available options cover a wide range of functional and aesthetic requirements.

It’s important to note that selecting the right material for a specific application is crucial for achieving desired functional properties and performance. Shapeways provides detailed material specifications and guidelines to help designers and manufacturers make informed decisions.

| Material | Key Properties | Applications |

|---|---|---|

| ABS | High strength, durability | Prototyping, functional parts |

| Nylon | Lightweight, flexible | Functional parts, fashion accessories |

| Stainless Steel | Corrosion resistant, high strength | Jewelry, mechanical components |

| Ceramics | Heat resistant, excellent surface finish | Dental, art, home decor |

Table: Examples of Materials offered by Shapeways

By combining state-of-the-art technology, advanced materials, and expertise, Shapeways empowers designers and manufacturers to embrace the possibilities of additive manufacturing. Whether it’s creating intricate jewelry, functional prototypes, or end-use parts, Shapeways provides the tools and resources to turn ideas into reality.

Shapeways Marketplace for Innovative 3D Printed Products

Shapeways has established itself as a leading marketplace for innovative 3D printed products. With thousands of designers from around the world, the marketplace offers a diverse range of unique and creative items. From intricate jewelry to functional prototypes, there is something for everyone.

Designers on the Shapeways Marketplace have access to a wide variety of materials, ensuring that their creations are not only visually appealing but also durable and high-quality. Whether it’s metal, plastic, or even ceramic, there are countless options to choose from. This allows designers to experiment and push the boundaries of what is possible with 3D printing.

The growth of the Shapeways Marketplace is a testament to the increasing popularity of 3D printed products. As more designers join the platform and add their creations, consumers have a wider selection of unique and personalized items to choose from. It’s a win-win for both designers and consumers, fostering a vibrant community of innovation and creativity.

| Benefits of the Shapeways Marketplace | Example Products |

|---|---|

| 1. Exposure – The marketplace provides designers with a global platform to showcase their work and gain exposure to a wider audience. | Custom-designed jewelry |

| 2. Revenue Generation – Designers can monetize their creations by selling them on the marketplace, turning their passion into a profitable business. | Functional prototypes |

| 3. Collaboration Opportunities – The marketplace fosters collaboration between designers, allowing them to learn from each other and create even more innovative products. | Miniature figurines |

| 4. Customer Feedback – Designers receive valuable feedback from customers, helping them improve their designs and tailor their products to meet market demands. | Decorative home accessories |

Being part of the Shapeways Marketplace is not just about selling products; it’s about being part of a creative community that is pushing the boundaries of what is possible with 3D printing. By joining the marketplace, you become part of a network of talented designers and innovators, with endless opportunities for collaboration and growth.

So whether you’re a designer looking to showcase your work, or a consumer in search of unique and personalized products, the Shapeways Marketplace is the place to be. Explore the vast selection, support independent designers, and be part of the 3D printing revolution.

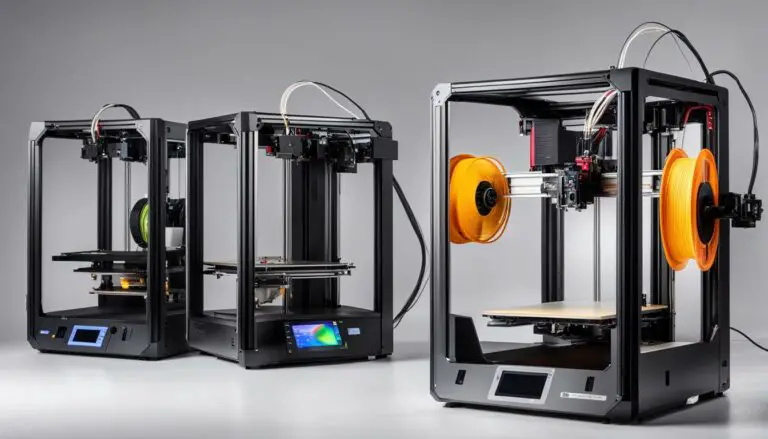

Shapeways Industrial Production for Manufacturers

If you’re a manufacturer looking for high-quality and versatile production services, Shapeways has you covered. With their expertise in additive manufacturing and injection molding, they offer a range of options tailored to your specific needs and requirements.

Shapeways utilizes technologies like Selective Laser Sintering (SLS) for large-volume runs and injection molding for mass production of parts. This flexibility allows you to choose the most suitable manufacturing method for your project, whether it’s for prototyping, testing, or producing end-use parts.

By partnering with Shapeways, you gain access to their state-of-the-art facilities and experienced team, ensuring that your products are produced to the highest standards. Their commitment to excellence and attention to detail make them a trusted partner for manufacturers across various industries.

Benefits of Shapeways Industrial Production

- Advanced technologies: Shapeways utilizes cutting-edge additive manufacturing and injection molding technologies, ensuring precision and accuracy in every part produced.

- Customization options: With Shapeways, you have the freedom to customize and iterate your designs without incurring additional costs or delays.

- Expert guidance: Shapeways’ team of experts is dedicated to providing guidance and support throughout the production process, assisting you in making informed decisions.

- Quality assurance: Shapeways has stringent quality control measures in place to ensure that every part meets the highest standards of quality and durability.

With Shapeways’ industrial production services, you can streamline your manufacturing process and bring your designs to life with confidence. Revolutionize your production capabilities today and partner with Shapeways.

Conclusion

Shapeways 3D Printing offers a versatile and cost-effective solution for a wide range of industries and applications. Whether you’re a designer looking to bring your unique creations to life or a manufacturer seeking efficient production methods, Shapeways has you covered.

With the ability to customize designs and access to a diverse range of materials and finishes, Shapeways empowers designers to unleash their creativity and produce high-quality 3D printed products. The fast iteration feature allows for quick modifications and optimizations without any additional cost or delay.

Manufacturers can also benefit from Shapeways’ industrial production services, which include technologies like Selective Laser Sintering (SLS) and injection molding. This versatility allows manufacturers to choose the most suitable technology for their specific needs and requirements.

In conclusion, Shapeways 3D Printing stands out as a leader in the industry. Their commitment to excellence in product development, coupled with the global marketplace for innovative 3D printed products, sets them apart from other 3D printing services. Revolutionize your design process and explore the endless possibilities of Shapeways today.

FAQ

What is Shapeways 3D Printing?

Shapeways 3D Printing is an online 3D printing service that offers a wide range of materials and finishes for custom 3D printing.

How does Shapeways compare to Protomold?

Shapeways and Protomold are both 3D printing services, but the cost of production can vary depending on factors like size and quantity. Shapeways is known for its versatility and cost-effectiveness, while Protomold may be cheaper for larger quantities.

What are the advantages of 3D printing over injection molding?

3D printing offers advantages like fast iteration, customization options, and the ability to modify designs without additional cost or delay.

What materials and finishes does Shapeways offer?

Shapeways offers over 90 materials and finishes, catering to various industries and consumer preferences.

What is the difference between additive manufacturing and 3D printing?

Additive manufacturing refers to the process of building a 3D product layer by layer from a CAD file, while 3D printing specifically denotes the use of a 3D printer to create the structure.

What is the Shapeways Marketplace?

The Shapeways Marketplace is a platform for designers to showcase and sell their 3D printed products, offering a wide range of unique and innovative creations.

What industrial production services does Shapeways provide?

Shapeways provides technologies like Selective Laser Sintering (SLS) and injection molding for large-volume runs and mass production of parts, catering to manufacturers’ specific needs and requirements.

Source Links

- https://www.shapeways.com/blog/archives/43289-3d-printing-and-additive-manufacturing-differences.html

- https://www.shapeways.com/blog/archives/1933-comparing-apples-and-oranges-injection-molding-vs-3d-printing.html

- https://www.shapeways.com/forum/t/shapeways-fine-detail-plastic-smooth-or-smoothest.101767/