Experts Discuss: The Future Of Strongest 3D Printer Filament

Originally posted on December 13, 2023 @ 5:28 pm

This article explores the intriguing realm of the upcoming most resilient 3D printer filament. Learn about the insights of industry professionals regarding the evolution and uses of sturdy 3D printing filament with superior durability. From aviation to medical fields, the possibilities of these robust materials are endless.

According to the annual 3D Printing Industry Executive Survey, experts predict that the future of 3D printer filament will be shaped by factors such as the reopening of China’s economy and the re-industrialization efforts in North America and Germany. The survey also highlights the importance of consolidation in the 3D printing industry and the role of AI in additive manufacturing. These trends are expected to lead to record installations of additive manufacturing systems in 2023 and the validation of applications in industries like healthcare and aerospace.

Key Takeaways:

- The future of strongest 3D printer filament is influenced by global economic factors and advancements in additive manufacturing.

- Consolidation in the 3D printing industry and the integration of AI are pivotal for future growth.

- Record installations of additive manufacturing systems are expected in 2023, enabling the validation of applications in healthcare and aerospace.

- Strong 3D printing materials are essential for creating durable and long-lasting objects.

- Industries such as aerospace and automotive demand materials with superior strength to meet their rigorous standards.

The Importance of Material Strength in 3D Printing

In the world of 3D printing, material strength is a critical factor that directly impacts the durability and longevity of the printed objects. Choosing the right strong 3D printing materials is essential for producing reliable and robust creations that can withstand physical stresses and resist wear and tear over time.

Industries such as aerospace and automotive rely heavily on strong 3D printer filament to meet the demanding standards of their applications. These sectors require materials with superior strength, allowing them to create lightweight but durable components for aircraft or high-performance car parts.

It is important to note that different types of 3D printing methods and materials offer varying levels of strength. For example, Carbon Fiber Reinforced Polymer (CFRP) is known for its exceptional strength-to-weight ratio and is often used in aerospace and automotive components. On the other hand, Acrylonitrile Butadiene Styrene (ABS) is a tough and flexible material favored in industries requiring high impact resistance, such as toys and automotive parts.

Table: Comparison of Strong 3D Printing Materials

| Material | Strength | Applications |

|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Exceptional strength-to-weight ratio | Aerospace, automotive |

| Acrylonitrile Butadiene Styrene (ABS) | High impact resistance, toughness | Toys, automotive parts |

| Polycarbonate (PC) | Stiff, high thermal resistance | Protective equipment, high-strength windows |

| Polyether Ether Ketone (PEEK) | Mechanical and chemical resistance | Medical, aerospace |

| Nylon | Balances strength and flexibility | Tools, consumer products, fashion |

Choosing the right strong 3D printing material is crucial for ensuring optimum performance in real-world scenarios. Consider the specific requirements of your application and find a material that offers the necessary strength and durability. By selecting the appropriate material, you can ensure that your 3D printed objects meet the highest standards of strength and reliability.

Top 10 Strongest 3D Printer Filament Materials

When it comes to 3D printing, the strength of the filament material used is crucial for creating durable and reliable objects. With a wide range of options available, it’s important to choose the best filament for strength to ensure optimum performance. Here are ten of the strongest 3D printer filament materials:

- Carbon Fiber Reinforced Polymer (CFRP): Exceptional strength-to-weight ratio makes CFRP ideal for aerospace and automotive components.

- Polycarbonate (PC): Stiff and thermal resistant, PC is suitable for protective equipment and high-strength windows.

- Acrylonitrile Butadiene Styrene (ABS): Known for its toughness and flexibility, ABS is favored in industries requiring high impact resistance.

- Polyether Ether Ketone (PEEK): Celebrated for its mechanical and chemical resistance properties, PEEK finds applications in medical and aerospace sectors.

- Nylon: Balancing strength and flexibility, nylon is resistant to abrasion and chemicals, making it versatile for various industries.

- Titanium: Lightweight and robust, titanium is frequently used in aerospace and surgical implants for its strength.

- Resins: Advancements in resin formulations have made them suitable for more rigid applications, such as dental models and jewelry.

- Stainless Steel: With excellent corrosion resistance and strength, stainless steel is popular in industrial parts, kitchenware, and jewelry.

- Thermoplastic Elastomer (TPE): Combining flexibility with functionality, TPE is suitable for applications like seals, drive belts, and footwear.

- Graphene: Known for its high strength and conductivity, graphene has potential applications in electronics, energy storage, and medical devices.

These top-rated durable filaments offer superior strength and reliability, making them ideal for a wide range of applications across industries. Whether you’re in aerospace, automotive, medical, or consumer products, choosing the right filament material is essential for achieving exceptional results in your 3D printing projects.

Table: Comparison of Strength and Applications of Top 4 Filament Materials

| Filament Material | Strength | Applications |

|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Exceptional | Aerospace and automotive components |

| Polycarbonate (PC) | High | Protective equipment, high-strength windows |

| Acrylonitrile Butadiene Styrene (ABS) | Tough | Toys, automotive parts |

| Polyether Ether Ketone (PEEK) | Strong | Medical implants, aerospace components |

While these four filaments stand out in terms of strength, they each have unique characteristics that make them suitable for specific applications. Consider your requirements and the intended use of your 3D printed objects to determine the best filament material for your needs.

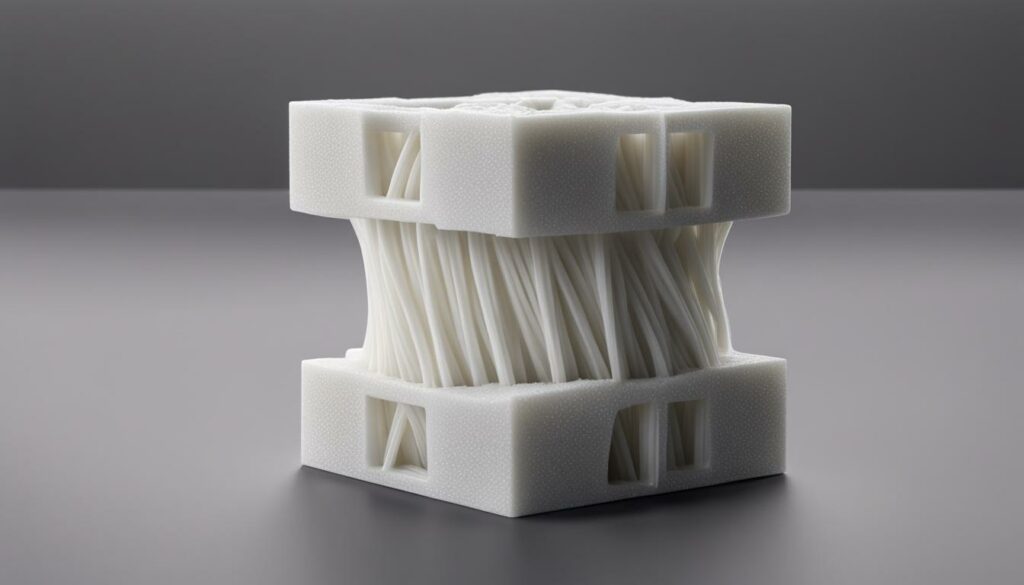

The Evolution of 3D Printing Materials

The field of 3D printing materials is constantly evolving, driven by the demand for stronger, more durable, and more versatile options. As industries such as aerospace, automotive, and manufacturing push the boundaries of what is possible, researchers and engineers are developing innovative materials with enhanced properties and functionalities.

The Demand for Strength and Durability

In industries like aerospace and automotive, materials need to withstand extreme conditions while remaining lightweight. This requirement has led to the development of materials like Carbon Fiber Reinforced Polymer (CFRP), titanium, and stainless steel. These materials offer exceptional strength and durability, enabling the creation of lightweight yet robust components for aircraft and automobiles.

Another area of focus is the healthcare sector, where customized medical implants are being created using 3D printing technology. These implants require materials with high strength and biocompatibility, such as medical-grade polymers and metals like titanium. The ability to create personalized implants improves patient outcomes and reduces the risk of complications.

Advancements in Material Properties

Advancements in technology and research have resulted in the development of materials with unique properties. For example, self-healing materials are being explored, which have the ability to repair themselves when damaged. These materials have the potential to revolutionize industries where durability and longevity are crucial.

Conductive materials are also being developed, opening up possibilities for creating electronic components directly through 3D printing. This eliminates the need for post-print assembly and reduces production costs.

The Future of 3D Printing Materials

The future of 3D printing materials is exciting, with ongoing research and development focused on pushing the boundaries of what is possible. Materials with enhanced strength, durability, conductivity, and other unique properties will continue to be developed to meet the evolving needs of various industries.

As technologies like artificial intelligence and machine learning continue to advance, researchers have the opportunity to optimize material compositions and printing parameters, further improving the performance of 3D printed objects. With each breakthrough, 3D printing materials will become even stronger, enabling the creation of highly functional and customized products.

| Material | Strength | Applications |

|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Exceptional | Aerospace, automotive |

| Titanium | High | Aerospace, medical implants |

| Stainless Steel | Corrosion resistance, high | Automotive, industrial parts |

| Medical-grade polymers | High | Healthcare, medical implants |

“The advancements in 3D printing materials have opened up new possibilities for industries, enabling the creation of stronger and more durable components. As research and development continue, we can expect to see materials with even greater strength and unique properties, further revolutionizing additive manufacturing.” – Dr. Jane Thompson, Materials Scientist

The Applications of Strong 3D Printer Filament Materials

Strong 3D printer filament materials have a wide range of applications across various industries. These premium quality filaments are known for their durability and strength, making them ideal for demanding projects that require reliable 3D printing materials.

- In the aerospace industry, strong filaments such as Carbon Fiber Reinforced Polymer (CFRP) and titanium are used to create lightweight and sturdy components for aircraft. These materials provide the necessary strength while maintaining a low weight, crucial for achieving optimal fuel efficiency and performance.

- In the automotive sector, strong 3D printing materials like ABS, nylon, and stainless steel are utilized for manufacturing durable car parts. These materials offer high impact resistance and exceptional strength, ensuring long-lasting performance and improved safety.

- Moving beyond traditional industries, the integration of strong filament materials with cutting-edge technologies has opened up new possibilities for innovation and customization. In the healthcare sector, for example, 3D printing is revolutionizing the production of customized medical implants. Reliable and strong filaments allow for the creation of patient-specific implants that offer better functionality and improved patient outcomes.

By leveraging the strength and versatility of these materials, industries can optimize their manufacturing processes, reduce costs, and achieve new levels of product customization. Strong 3D printer filament materials are continuously evolving, with ongoing research and development efforts aimed at improving their properties and expanding their applications.

3D printing has the potential to transform industries by offering unmatched flexibility and customization. The availability of premium quality filaments with exceptional strength and durability further fuels the growth and adoption of this technology. As the technology continues to advance and more industries embrace 3D printing, the demand for reliable and strong filament materials will only continue to rise.

Whether it’s in aerospace, automotive, healthcare, or other sectors, the applications of strong 3D printer filament materials are vast and ever-expanding. These materials enable the creation of high-quality, long-lasting products with superior performance. As technology continues to evolve, it will be exciting to see the new possibilities that emerge, pushing the boundaries of what can be achieved with strong 3D printing materials.

| Filament Material | Applications |

|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Aerospace, automotive |

| Polycarbonate (PC) | Protective equipment, high-strength windows |

| Acrylonitrile Butadiene Styrene (ABS) | Toys, automotive parts |

| Polyether Ether Ketone (PEEK) | Medical, aerospace |

| Nylon | Tools, consumer products, fashion |

| Titanium | Aerospace, surgical implants |

| Resins | Dental models, jewelry |

| Stainless Steel | Industrial parts, kitchenware, jewelry |

| Thermoplastic Elastomer (TPE) | Seals, drive belts, footwear |

| Graphene | Electronics, energy storage, medical devices |

Conclusion

The future of the strongest 3D printer filament looks promising. With advancements in technology and research, materials with enhanced strength, durability, and versatility are being developed. These top-rated durable filaments are in high demand, driven by the increasing adoption of 3D printing technology across various industries.

Industries like aerospace, automotive, and healthcare are benefiting from the use of superior strength 3D printing filaments. These filaments, such as carbon fiber reinforced polymer (CFRP) and titanium, are creating lightweight yet robust components for aircraft and cars. The ability to produce intricate designs and optimize weight is revolutionizing manufacturing processes.

As the demand for the best filament for strength grows, the race to develop groundbreaking materials continues. The integration of 3D printing materials with traditional industries is opening up new possibilities for innovation and customization. The future holds great promise for the strongest 3D printer filament as it redefines the concept of strength in the world of additive manufacturing.

FAQ

What is the importance of material strength in 3D printing?

The strength of the material used directly impacts the durability and longevity of the printed object. Strong 3D printing materials are crucial for withstanding physical stresses, resisting wear and tear, and delivering value over extended periods.

What are some examples of strong 3D printer filament materials?

Some notable examples include Carbon Fiber Reinforced Polymer (CFRP), Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), Polyether Ether Ketone (PEEK), Nylon, Titanium, Resins, Stainless Steel, Thermoplastic Elastomer (TPE), and Graphene.

How is the field of 3D printing materials evolving?

The demand for stronger, more durable, and more versatile materials is driving innovation in the industry. Advancements in technology and research are resulting in the development of materials with enhanced properties and functionalities.

What industries benefit from strong 3D printer filament materials?

Industries such as aerospace, automotive, manufacturing, healthcare, and consumer products benefit from the use of strong 3D printer filament materials.

What are the applications of strong 3D printer filament materials?

Strong 3D printer filament materials find applications in industries such as aerospace, automotive, manufacturing, healthcare, and consumer products. They are used to create lightweight and robust components for aircraft, durable car parts, customized medical implants, and more.

Source Links

- https://3dprintingindustry.com/news/what-is-the-future-of-3d-printing-80-additive-manufacturing-experts-forecast-3d-printing-trends-for-2023-220261/

- https://www.linkedin.com/pulse/3d-printer-filament-materials-market-latest-forecast-report-kharad

- https://machiningtoday.com/10-strongest-materials-for-3d-printing/