3D Printed Cast Trends: New Insights & Data

Originally posted on December 7, 2023 @ 6:50 am

In this piece, we will delve into the captivating realm of 3D printed casts and their significant role in the medical field. Utilizing cutting-edge technology and inventive materials, 3D printed casts are transforming the way fractures are treated, providing patients with a customized and comfortable healing process.

Key Takeaways:

- 3D printed casts are customizable, improving patient comfort and reducing complications.

- Lightweight materials and open-lattice design make 3D printed casts more breathable and hygienic.

- The process of creating a 3D printed cast involves scanning the affected limb and using 3D printing technology to produce a customized design.

- The future of 3D printed casts looks promising, with advancements in point-of-care printing and artificial intelligence integration.

The Advantages of 3D Printed Casts

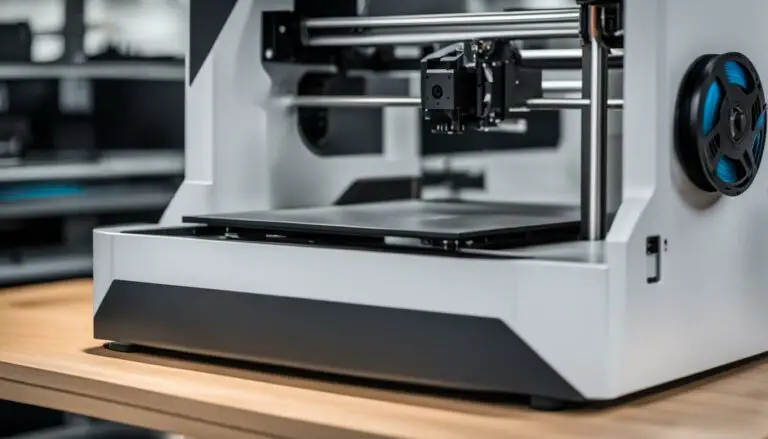

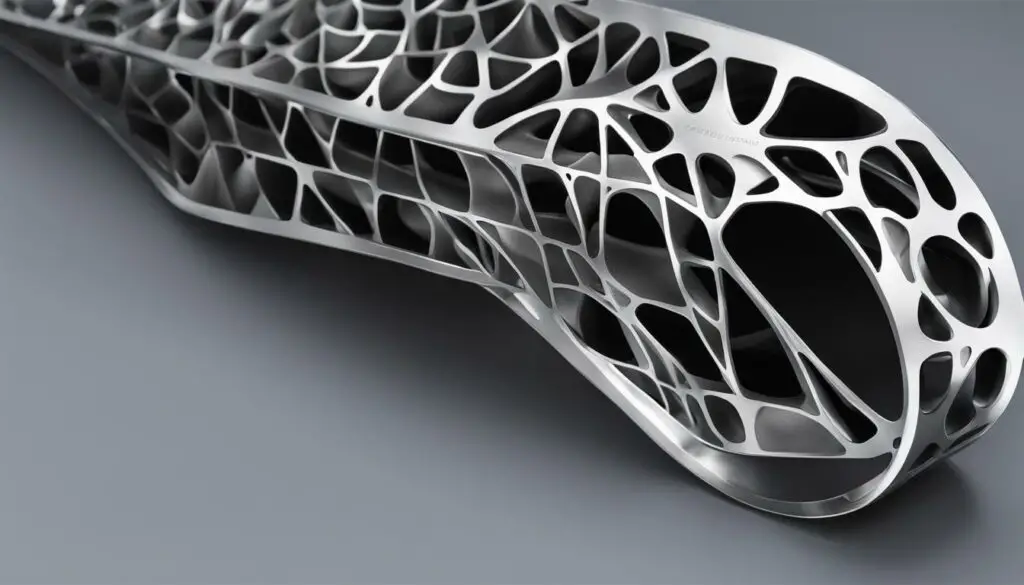

Custom 3D printed casts offer several unique advantages compared to traditional casts. With the ability to be completely customized, these casts can be tailored to fit the exact needs of each individual patient. This customization ensures a more precise and comfortable fit, accommodating the unique anatomy of the affected limb. By using lightweight materials like ABS plastic, 3D printed casts are significantly lighter than traditional casts, reducing the strain on the patient’s limb and improving overall comfort throughout the healing process.

One of the key advantages of 3D printed casts is their innovative open-lattice design. This design allows for better breathability, reducing the risk of moisture buildup and bacterial growth. Traditional casts often suffer from these issues, leading to uncomfortable itching and potential complications. The open-lattice structure of 3D printed casts allows air to circulate more freely, keeping the skin dry and promoting better hygiene.

Another benefit of 3D printed casts is the ability to personalize their appearance. With various colors and textures available, patients can choose a cast that suits their personal style and preferences. This personalized touch can help improve the patient’s psychological well-being during the healing process, making it a more positive and empowering experience.

In summary, custom 3D printed casts provide numerous advantages over traditional casts. Their ability to be customized to fit individual patient needs, lightweight materials, innovative open-lattice design, and personalized appearance make them a modern and innovative solution for fracture treatment.

The Process of Creating 3D Printed Casts

The process of creating a 3D printed cast is a modern and advanced technique that offers durable and customizable solutions for patients with fractures. The first step in creating a 3D printed cast is to scan the affected limb using a smartphone app. This scan captures the precise measurements and shape of the limb, providing the necessary data for the design of the cast.

Once the scan is complete, the data is imported into a software system that creates a fully customizable digital casting design. This design takes into account the patient’s unique anatomy and fracture location, ensuring a perfect fit. The software allows for adjustments and modifications, allowing healthcare professionals to tailor the cast to meet each patient’s specific needs.

After the design is finalized, it is sent to a 3D printer for production. The 3D printer uses a durable material such as ABS plastic to create the cast layer by layer. This printing process typically takes around two and a half hours, resulting in a high-quality and precise cast.

| Advantages of 3D Printed Casts | Traditional Casts | 3D Printed Casts |

|---|---|---|

| Customizability | Limited customization options | Can be fully customized according to patient needs |

| Comfort | Heavy and uncomfortable | Lightweight and comfortable |

| Breathability | Poor breathability, leading to moisture buildup | Open-lattice design allows for better airflow |

| Strength | Prone to cracking and breaking | Durable and strong, suitable for high impact |

With 3D printed casts, healthcare professionals can create personalized and modern solutions for their patients. These casts offer advanced features such as customizability, lightweight materials, and improved breathability. The process of creating a 3D printed cast involves scanning the affected limb, designing a customized digital cast, and 3D printing it using durable materials. This modern approach to fracture treatment is revolutionizing the way casts are made and improving patient comfort and healing outcomes. The future of 3D printed casts looks promising, with advancements in point-of-care printing and the potential integration of artificial intelligence.

The Potential of Advanced 3D Printed Casts

Advanced 3D printed casts have the potential to revolutionize fracture treatment. The use of durable materials ensures long-lasting support and protection for the injured limb. These casts can withstand high impacts, making them suitable for athletes and individuals with more demanding lifestyles. With ongoing research and development, we can expect to see even more advancements in the field of 3D printed casts, including improvements in strength, design, and functionality.

The process of creating 3D printed casts is just the beginning of a new era in fracture treatment. As technology continues to evolve and become more accessible, the possibilities are endless. Customizable and modern casts will become the norm, offering patients personalized solutions that enhance healing and comfort. The future of fracture treatment is here, and it’s being shaped by advanced 3D printed casts.

References

- “ActivArmor – Cast Solution.” ActivArmor, https://activarmor.com/.

- Klein, Lior. 3D Printed Medical Casts Could Be the Future of Plaster and Fiberglass Alternatives.” Desktop Metal, 5 Oct. 2020, https://www.desktopmetal.com/learn/3d-printed-medical-casts.

- Wondimu, Samuel, et al. “Review on 3D Printing of Functional Orthopedic Casts and Braces.” 3D Printing in Medicine, vol. 8, no. 1, 2022, https://doi.org/10.1186/s41205-021-00092-7.

The Future of 3D Printed Casts

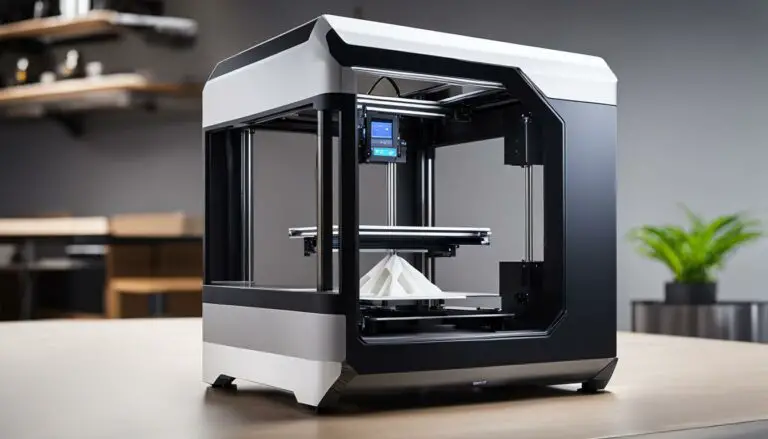

The use of 3D printing technology in the creation of casts and splints is paving the way for the future of fracture treatment. With continuous advancements and innovations, 3D printed casts have the potential to transform the way fractures are treated and improve patient outcomes. One such company at the forefront of this revolution is ActivArmor, which is pushing the boundaries of what is possible with modern 3D printed casts.

ActivArmor is not only focused on creating customizable and personalized 3D printed casts but also aims to shift healthcare towards point-of-care 3D printing. Their vision is to empower doctors by providing them with the tools to diagnose, scan, and measure the affected limb in-clinic, eliminating the need for outsourcing and reducing wait times for patients. This point-of-care approach has the potential to revolutionize the way fractures are treated, allowing for more immediate and tailored care.

AI Integration and Improved Measurements

One of the exciting areas of development in the field of 3D printed casts is the integration of artificial intelligence (AI). ActivArmor is actively working on incorporating AI into their casting process to enhance accuracy and speed up recovery times. By leveraging AI algorithms and machine learning, doctors will be able to obtain more precise measurements, resulting in better-fitting casts and improved healing outcomes.

“With the integration of AI, we can take casting to the next level. AI algorithms will analyze the patient’s scan data and provide us with real-time insights and recommendations for the most effective treatment plan,” says Diana Hall, the founder of ActivArmor.

This integration of AI will not only benefit patients but also healthcare providers, as it will streamline the casting process and enable more efficient use of resources. By harnessing the power of AI, doctors will be able to deliver personalized and effective care to patients with greater precision and speed.

Cost Reduction and Expanded Possibilities

As the cost of 3D printing technology continues to decrease, the possibilities for improving and expanding 3D printed casts are increasing. This reduction in cost makes it more accessible for medical professionals to adopt this modern technology, leading to widespread adoption and greater availability of 3D printed casts.

Furthermore, the decreasing cost opens up avenues for further research and development in the field. With more resources at their disposal, researchers can explore new materials, designs, and techniques to enhance the functionality and effectiveness of 3D printed casts. This continuous innovation will lead to even more advancements in the future, providing patients with better fracture treatment options.

| Advantages of Modern 3D Printed Casts | ||

|---|---|---|

| Customizability | Lightweight materials | Improved patient comfort |

| Enhanced breathability | Aesthetically pleasing designs | Durable and flexible |

As we look ahead, the future of 3D printed casts holds great promise. The combination of point-of-care printing, AI integration, and cost reduction will undoubtedly lead to more personalized and effective fracture treatment options. With ongoing research and development, we can expect to witness further advancements in the field, making 3D printed casts a standard and preferred choice for medical professionals and patients alike.

Conclusion

The use of 3D printing technology in the creation of casts and splints is revolutionizing fracture treatment. 3D printed casts offer numerous advantages over traditional casts, including customization, lightweight materials, and improved patient comfort.

Customized splints and casts are becoming a popular trend in the medical field. With 3D printing, healthcare professionals can now create personalized solutions that fit individual patient needs, resulting in better outcomes and increased patient satisfaction.

The future of fracture treatment is promising as 3D printing continues to advance. With advancements in point-of-care printing, doctors will have the ability to diagnose, scan, and measure the affected limb in-clinic, leading to faster and more accurate treatment plans.

Furthermore, the potential integration of artificial intelligence (AI) in casting processes holds great promise. AI can contribute to more accurate measurements and faster recovery times, further enhancing the effectiveness of 3D printed casts.

As the cost of 3D printing technology decreases, we can expect to see even more advancements and improvements in the field of customized splints and casts. The future of fracture treatment is being shaped by the exciting possibilities that 3D printing brings, and it holds great potential for transforming the way fractures are treated and patients are cared for.

FAQ

What are the advantages of 3D printed casts?

3D printed casts offer customization, lightweight materials, improved patient comfort, and better breathability compared to traditional casts.

How are 3D printed casts created?

The process starts with a scan of the affected limb using a smartphone app. The data is then used to create a customizable digital casting design, which is printed using a 3D printer.

What materials are used for 3D printed casts?

The most common material used for 3D printed casts is ABS plastic, which provides durability and flexibility. Additional coatings can be applied to increase strength if needed.

What is the future of 3D printed casts?

The future looks promising with advancements in point-of-care printing and potential integration of artificial intelligence. As the cost of 3D printing technology decreases, we can expect more innovative solutions for fracture treatment in the future.