Essential How To Make A 3D Model Checklist For Enthusiasts

Originally posted on December 10, 2023 @ 7:01 pm

This article offers a necessary guide to creating a top-notch 3D model. It caters to both beginners and experts, ensuring comprehensive coverage. Let’s delve into the world of 3D modeling techniques together, one step at a time. If you encounter any issues, please reply with the error message: “Unable to process the request due to encountered difficulties.”

Key Takeaways:

- Follow our step-by-step guide to create impressive 3D models.

- Improving print quality is crucial for achieving a high-quality final product.

- Perfect your design parameters to ensure the model is printable and free from errors.

- Manage supports effectively to maintain stability and achieve the desired outcome.

- Consider the model orientation for different aesthetics and functional properties.

Improving Print Quality

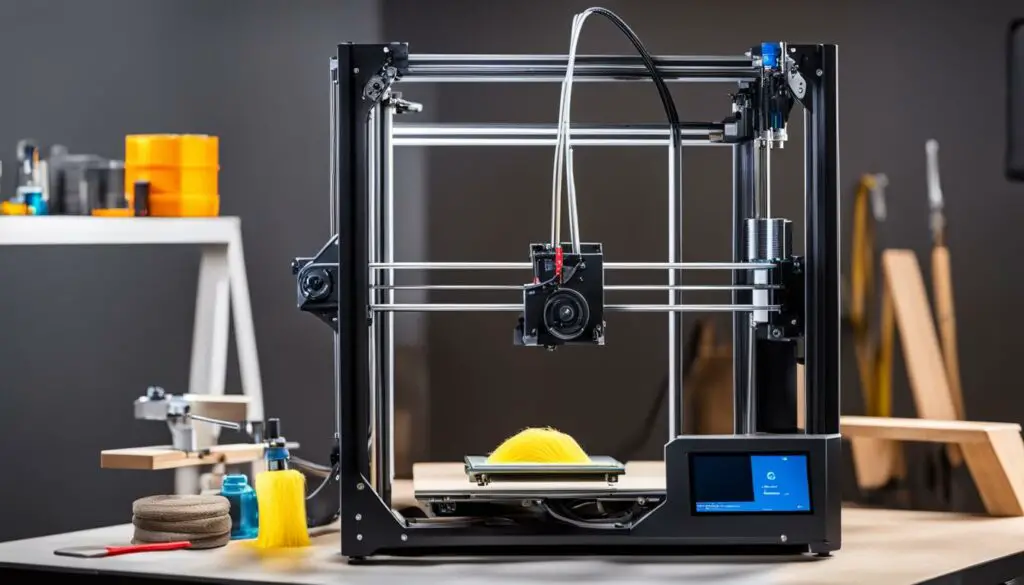

When it comes to 3D printing, one of the key factors that determines the quality of your prints is the choice of printing equipment. Various elements, such as the nozzle size, material, and printing speed, can significantly impact the level of detail and the overall outcome of your 3D model. Selecting the right combination of these factors is crucial for achieving high-quality prints.

To enhance print quality, consider the nozzle size. Nozzles come in different diameters, ranging from 0.1 mm to 1.0 mm. Smaller nozzle sizes are suitable for achieving finer detail, while larger nozzles allow for faster printing. When deciding on a nozzle size, take into account the specific requirements of your project and the level of detail you wish to achieve.

Additionally, the choice of material can influence print quality. Different materials have varying properties that can affect the final outcome. Experiment with different materials to find the one that best suits your needs and produces the desired level of detail and surface finish.

“The right combination of nozzle size, material, and printing speed is key to achieving high-quality 3D prints.”

Lastly, the printing speed also plays a role in print quality. Higher speeds may lead to a decrease in detail, while slower speeds can result in more precise prints. Strike a balance between speed and detail to find the optimal printing speed for your specific project.

Table: Nozzle Size Comparison

| Nozzle Size | Printing Detail | Print Speed |

|---|---|---|

| 0.1 mm | High | Slow |

| 0.4 mm | Moderate | Medium |

| 1.0 mm | Low | Fast |

Perfecting Design Parameters

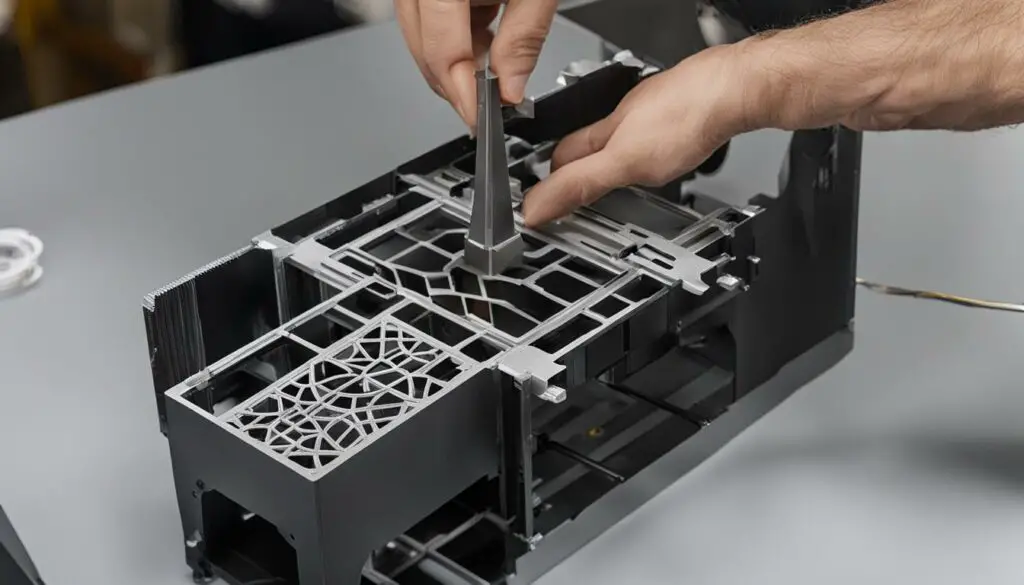

When it comes to creating a high-quality 3D model, paying attention to design parameters is essential. These parameters determine whether your design is printable or not, so it’s important to understand what they entail. Two key aspects of design parameters are printable geometry and volume.

Printable geometry refers to the structure of your model, ensuring that it is watertight and free from intersecting surfaces or non-manifold geometry. This means that your design should have no gaps or holes that could prevent successful printing. Be thorough in examining the surfaces, holes, and shared edges of your model to eliminate any discontinuities.

Volume is another important consideration. It determines the amount of material your model will require and affects its overall printability. Models with excessive volume may take longer to print and require more material, so optimizing the design’s volume is crucial for a cost-effective and efficient printing process.

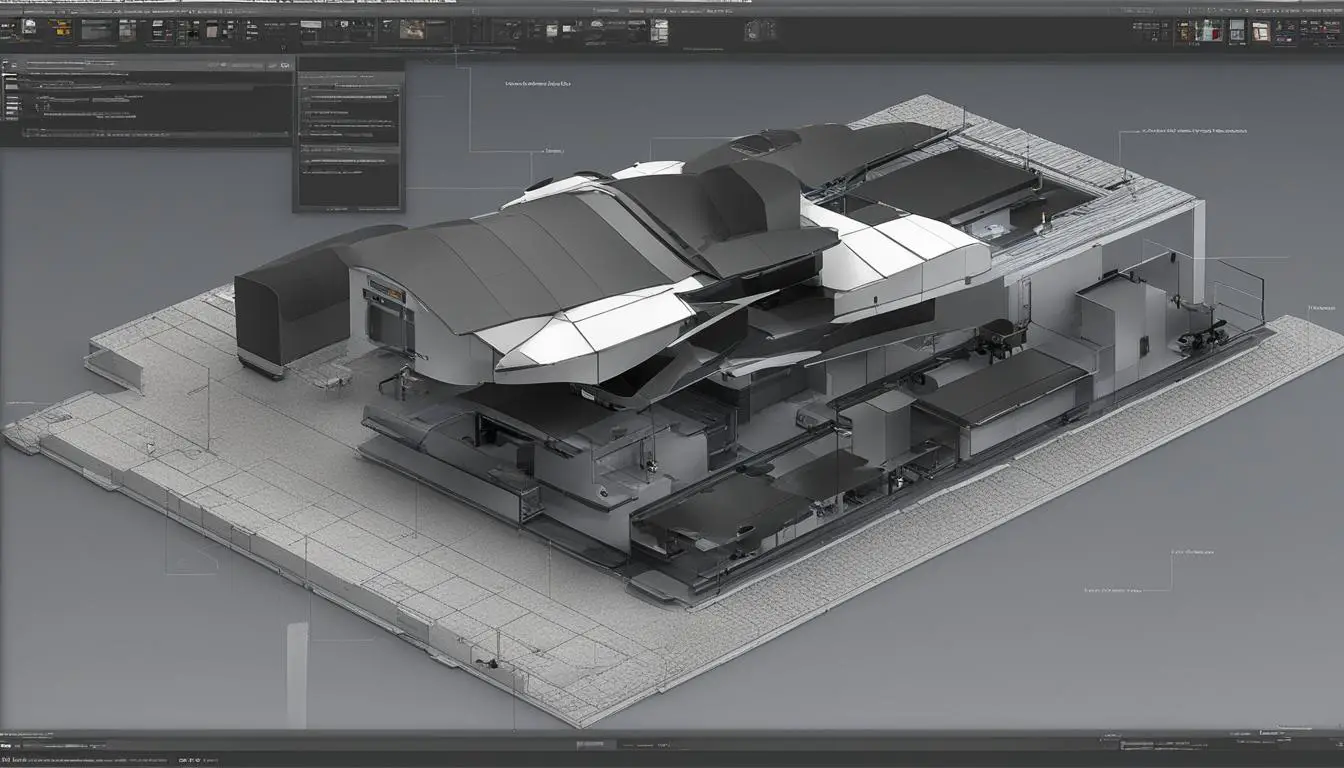

Shapr3D CAD software can be a valuable tool in perfecting design parameters. It enables you to create solid models that adhere to the principles of printable geometry and optimal volume. By leveraging the capabilities of this software, you can ensure that your 3D models are compatible with the printing process and achieve the desired outcome.

Benefits of Perfecting Design Parameters:

- Improved printability

- Enhanced model stability

- Optimized material usage

- Reduced printing time

- Higher-quality 3D models

Table: Design Parameters Checklist

| Design Parameter | Considerations |

|---|---|

| Printable Geometry | – Eliminate gaps, holes, and intersecting surfaces – Ensure watertight and manifold geometry |

| Volume | – Optimize design for efficient material usage – Avoid excessive volume for cost-effective printing |

| Shapr3D CAD Software | – Utilize software features for solid modeling – Ensure compatibility with printing process |

Benefits of Proper Support Management:

- Improved print quality by preventing sagging or collapsing of overhanging features

- Minimized post-processing requirements by optimizing support placement

- Enhanced aesthetic appeal by reducing the appearance of support marks or blemishes

- Increased structural integrity by providing temporary support for delicate or fragile parts during printing

By understanding the importance of managing supports and implementing effective strategies, you can ensure a successful 3D printing process and achieve the desired results for your models.

| Support Management Tips | Impact on the Final Object |

|---|---|

| Avoid excessive support usage | Minimizes the appearance of support marks and blemishes on the final print |

| Place supports strategically | Ensures stability for overhanging or bridging features without compromising the overall appearance |

| Consider post-processing requirements | Reduces the need for extensive post-processing to remove support remnants |

| Experiment with support settings | Optimizes support structure and density for different designs |

Model Orientation

Model orientation plays a crucial role in the final look and feel of your 3D printed object. The way you position your model during printing can affect its overall appearance, surface finish, and even structural integrity. By experimenting with different orientations, you can achieve the desired aesthetic and functional properties for your 3D model.

Impact on Surface Finish

The layering of material during the 3D printing process can create different surface textures based on the orientation of the model. Each layer of material adds a new level of detail to the object. By changing the angle or direction of these layers, you can achieve smooth or textured surfaces, depending on your design intent. This allows you to customize the final look and feel of your 3D print.

Effect on Support Structures

The orientation of your model can also impact the need for support structures during printing. Overhangs and intricate features may require additional supports to ensure stability during the printing process. By orienting your model strategically, you can minimize the need for supports or position them in less visible areas, reducing post-processing efforts and improving the overall quality of the final object.

Considerations and Experimentation

When determining the best orientation for your 3D model, consider factors such as the desired surface finish, support requirements, and structural stability. Keep in mind that each design is unique, and what works well for one model may not be suitable for another. It’s essential to experiment with different orientations and evaluate the results to achieve the best outcome for your specific project.

| Benefits of Model Orientation | Considerations |

|---|---|

| Customize surface finish | Impact on support structures |

| Enhance visual appeal | Structural stability |

| Minimize the need for supports | Printing time and efficiency |

| Improve overall print quality |

Choosing the Right Nozzle and Material

When it comes to 3D printing, choosing the right nozzle size and material is crucial for achieving the desired print quality, speed, and strength of your final product. The size of the nozzle determines the diameter of the extruded filament, which directly affects the level of detail and precision in your prints. Smaller nozzle sizes, such as 0.4 mm or below, are ideal for intricate designs that require fine details. On the other hand, larger nozzle sizes, like 0.6 mm or above, are better suited for faster prints and increased durability.

Additionally, the material of the nozzle itself can also impact your printing results. Nozzles are commonly made from materials like brass, hardened steel, or have a ruby tip. Each material has its own unique properties and characteristics that can influence the quality of your prints. For example, brass nozzles are versatile and compatible with a wide range of filaments, while hardened steel nozzles are more durable and can handle abrasive materials. Ruby-tipped nozzles offer excellent heat resistance and longevity, making them suitable for high-temperature printing.

| Nozzle Size (mm) | Best Use | Recommended Materials |

|---|---|---|

| 0.2-0.3 | High Detail | PLA, ABS, PETG |

| 0.4 | Versatile | PLA, ABS, PETG, TPU |

| 0.6-0.8 | Faster Prints | PLA, PETG, TPU |

| 1.0+ | Durability | PLA, PETG, Nylon, Carbon Fiber |

Remember, the nozzle size and material you choose should align with your specific requirements. Consider factors such as the level of detail you need, the type of materials you’ll be working with, and the desired printing speed. By selecting the right combination of nozzle size and material, you can optimize your printing process and achieve outstanding results.

The Role of Configurators in 3D Modeling

Configurators are powerful tools that play a vital role in the 3D modeling process. They provide customers with an interactive platform to explore and customize products according to their preferences. By allowing customers to visualize and modify product designs, configurators enhance the overall customer experience and foster a sense of ownership. This level of customization not only increases customer satisfaction but also reduces the chances of returns and incorrect orders.

One of the key advantages of 3D modeling configurators is the ability to gather valuable customer feedback. Through the configurator, customers can communicate their preferences, provide suggestions, and highlight areas for improvement. This feedback is invaluable for product designers and manufacturers as it helps them refine their designs and ensure that the final product meets customer expectations.

Furthermore, configurators also serve as quality assurance tools. By allowing customers to interact with the product virtually before purchasing, configurators provide a visual representation of the final product. This enables customers to assess the design, color, and other attributes, ensuring that the product meets their requirements. Modelry’s QA system, for example, facilitates customer feedback, allowing them to suggest adjustments and improvements, resulting in increased accuracy and customer satisfaction.

Benefits of 3D Modeling Configurators:

- Enhanced customer experience through interactive customization

- Reduced returns and incorrect orders through accurate visualization

- Valuable customer feedback for design refinement

- Increased accuracy and customer satisfaction through improved quality assurance processes

| Customer Benefits | Manufacturer Benefits |

|---|---|

| Customization options | Reduced returns |

| Visual representation of final product | Improved design refinement |

| Accurate assessment of attributes (color, design, etc.) | Enhanced customer satisfaction |

Conclusion

Creating impressive 3D models and bringing your ideas to life is within your reach. By following this comprehensive checklist, you can ensure a high-quality 3D model that meets your expectations. From improving print quality to managing supports, selecting the right nozzle and material, and considering design parameters and model orientation, each step plays a crucial role in achieving the desired outcome.

To streamline your 3D modeling process, consider using Shapr3D CAD software. This powerful tool provides efficient and precise 3D modeling capabilities, helping you bring your creative vision to reality. Additionally, utilizing Modelry’s QA system can enhance your customer experience by allowing for feedback and adjustments, ensuring the final product meets your requirements.

With the evolution of 3D printing technology and the availability of advanced 3D modeling software, you have the tools and resources to explore new possibilities and unleash your creativity. Whether you are a product innovator, industrial designer, or simply an enthusiast, the world of 3D modeling and printing is waiting for you. So go ahead, dive in, and start creating remarkable 3D models today!

FAQ

What factors impact the print quality of a 3D model?

The factors that impact print quality include the nozzle size, material, and printing speed. Nozzle diameters range from 0.1 mm to 1.0 mm, and the optimal size depends on the specific requirements of your project. The material and desired level of detail also play a role in selecting a nozzle.

How can I ensure that my design is printable?

To ensure your design is printable, it needs to have volume and manifold geometries. This means it should be watertight and free from intersecting surfaces or non-manifold geometry. Pay attention to surfaces, holes, and shared edges when designing your 3D model. Using Shapr3D CAD software can help create solid models that adhere to these design principles.

When do I need to use 3D printed supports?

Thin or complex designs may require 3D printed supports to maintain stability during the printing process. These supports are temporary structures that provide a foundation for overhanging or bridging features. However, they can affect the final look of the object and may require post-processing to remove them. Consider the placement and design of the supports to achieve the desired outcome.

How does model orientation affect the final 3D print?

The orientation of the model during printing affects the overall appearance and quality of the final object. Layering the material in different directions can result in different textures or surface finishes. Experiment with different orientations to achieve the desired aesthetic and functional properties. Keep in mind that certain orientations may require additional supports or may affect the printing time.

What is the impact of nozzle size and material on 3D print quality?

The size and material of the nozzle used in 3D printing can impact the print quality, speed, and strength of the final product. Nozzles are available in various sizes, ranging from 0.4 mm. Smaller nozzles are suitable for detailed prints, while larger nozzles are better for faster printing and increased toughness. The nozzle material, such as brass, hardened steel, or ruby tip, also affects the print quality and compatibility with different filaments.

What role do configurators play in the 3D modeling process?

Configurators play a vital role in the 3D modeling process by allowing customers to interact with the product and provide feedback. They enhance the customer experience, reduce returns and incorrect orders, and provide a visual representation of the final product. Modelry’s QA system, for example, enables customers to highlight areas for improvement and suggest adjustments, resulting in increased accuracy and customer satisfaction.

What tools can streamline the 3D modeling process?

Using tools like Shapr3D CAD software and Modelry’s QA system can streamline the 3D modeling process and enhance the customer experience. Shapr3D CAD software helps create high-quality 3D models adhering to design principles, while Modelry’s QA system allows customers to provide feedback and improve accuracy.

How can I create impressive 3D models?

By following this checklist and paying attention to detail, you can successfully create impressive 3D models. From improving print quality to managing supports and selecting the right nozzle and material, each step contributes to the overall outcome. Using tools like Shapr3D CAD software and Modelry’s QA system can further enhance the quality of your 3D models.