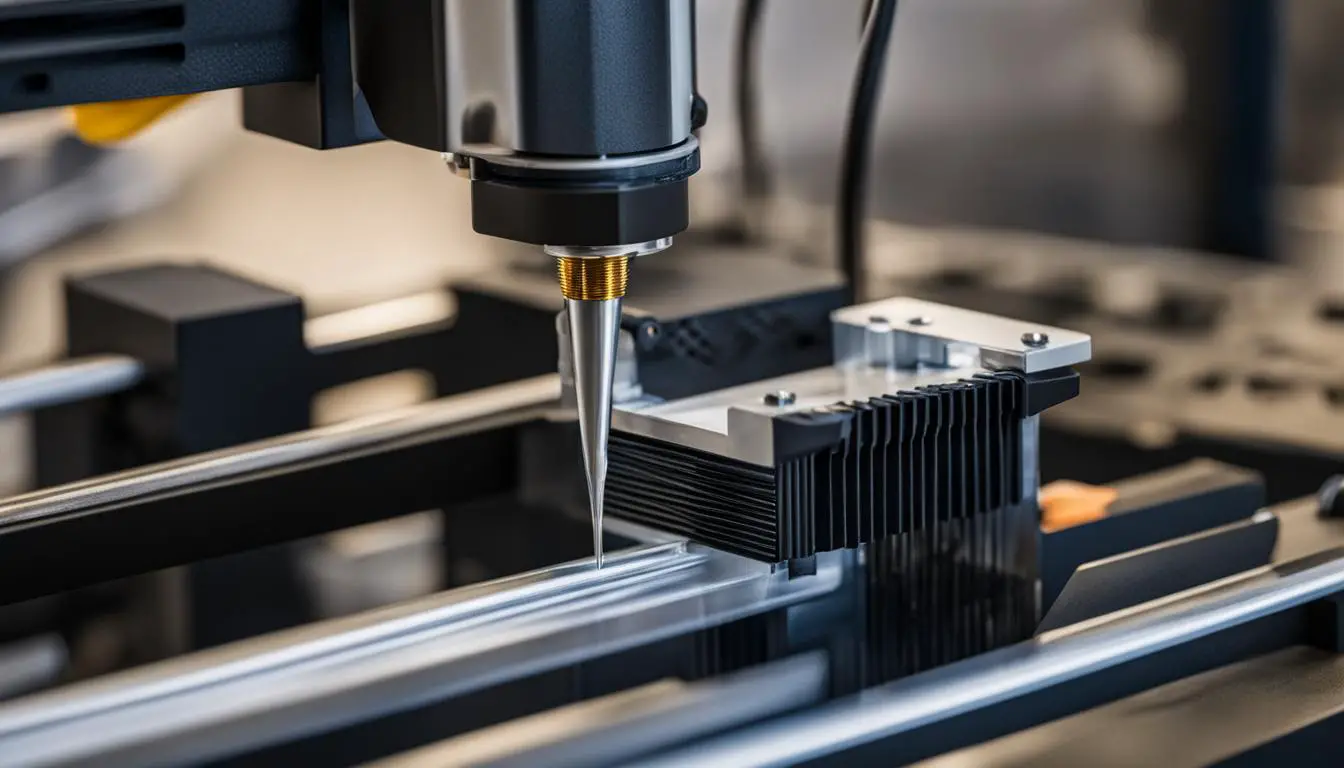

How To Master Stratasys 3D Printer In Easy Steps

Originally posted on December 3, 2023 @ 10:28 pm

This article will assist you in mastering the Stratasys 3D printer, a well-known name in the world of 3D printing technology and additive manufacturing. Whether you are new or experienced with this technology, we have you covered with tips to improve your skills. Let’s delve into how you can become proficient in utilizing this advanced additive manufacturing solution.

Key Takeaways:

- Understand the different applications and design considerations of the Stratasys 3D printer.

- Optimize file preparation, post-processing options, and material selection for high-quality 3D printing.

- Export your CAD files as STL files and ensure proper file optimization.

- Familiarize yourself with design guidelines and support structures specific to Stratasys 3D printing.

- Explore the range of post-processing options available for Stratasys 3D prints.

Exporting Your CAD Files as STL

Before you can bring your designs to life on a Stratasys 3D printer, you need to export your CAD files in the proper format. The STL (Standard Tessellation Language) file format is commonly used for 3D printing as it consists of triangles that form the surface of your part. This file format ensures that your design is accurately translated into a printable file that the 3D printer can understand.

When exporting your CAD files as STL, it’s important to consider the quality and integrity of your design. One aspect to pay attention to is 3D model faceting, which determines the level of detail in the printed part. By adjusting the faceting settings in your CAD software, you can control the smoothness of your model’s surface and the number of triangles used to represent it.

An important step in preparing your CAD files for 3D printing is file optimization. This involves considering parameters such as chord height, deviation, angle tolerance, and poly count. By optimizing your files, you can achieve better results in the 3D printing process, ensuring that your parts are accurate, high-quality, and free from errors or imperfections.

Table: File Optimization Parameters

| Parameter | Description |

|---|---|

| Chord Height | The maximum distance between the original CAD model and the triangle that approximates its surface. Smaller chord height values result in higher quality but larger file sizes. |

| Deviation | The maximum distance between the original CAD model and the triangle that approximates its surface. Smaller deviation values result in higher quality but larger file sizes. |

| Angle Tolerance | The angle at which two triangle edges are merged into a single edge. Smaller angle tolerance values result in higher quality but larger file sizes. |

| Poly Count | The number of triangles used to approximate the surface of the CAD model. Higher poly counts result in higher detail but larger file sizes. |

By understanding the process of exporting CAD files as STL and optimizing those files, you can ensure that your designs are ready for successful 3D printing on a Stratasys 3D printer. Remember to pay attention to the file optimization parameters and adjust them according to your specific project requirements.

Continue reading to explore the various post-processing options available for enhancing the appearance and functionality of your Stratasys 3D prints.

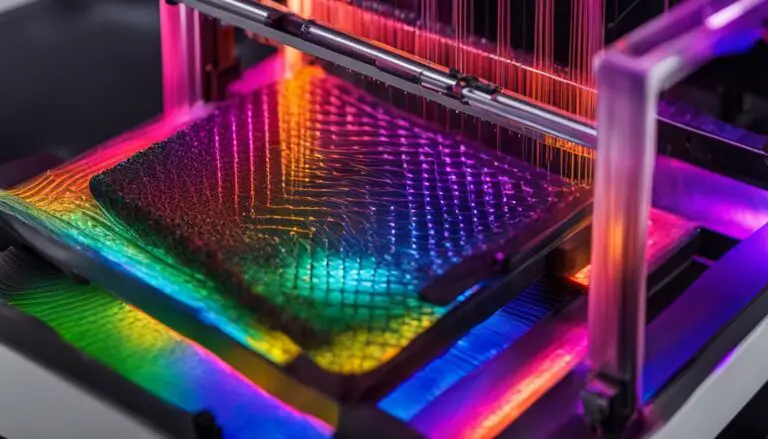

Post-Processing Options for Stratasys 3D Prints

After your Stratasys 3D prints have been successfully printed, it’s time to explore the world of post-processing options that can enhance the final appearance and functionality of your printed parts. Stratasys offers a variety of post-processing techniques that allow you to achieve the desired surface finish and optimize your prints for functional or cosmetic purposes.

Finishing Options

When it comes to post-processing, you have a range of finishing options to choose from based on your specific requirements. Some common techniques include:

- Media blasting: This process involves using abrasive materials to remove any roughness or imperfections on the surface of the printed part.

- Tumbling: Tumbling is a technique that involves placing the printed part in a drum or chamber along with abrasive media. The rotation of the drum helps to smooth out the surface of the part.

- Bonding and sealing: These techniques are used to strengthen the printed part and prevent any material degradation. Bonding involves joining multiple parts together, while sealing creates a protective layer on the surface.

- Sanding: Sanding is a manual process that involves using sandpaper or other abrasive materials to smooth out rough surfaces and achieve a desired level of finish.

- Painting and clear coating: These techniques are used to enhance the visual appearance of the printed part. Painting adds color and texture, while clear coating provides a protective layer and a glossy finish.

Functional Finishes vs. Cosmetic Finishes

When considering post-processing options, it’s important to understand the difference between functional finishes and cosmetic finishes. Functional finishes focus on improving the mechanical properties and performance of the printed part, while cosmetic finishes are primarily concerned with the visual appearance.

“Post-processing plays a crucial role in optimizing the final appearance and functionality of 3D printed parts.”

For functional finishes, techniques such as media blasting, tumbling, bonding, and sealing are often utilized. These methods can help to strengthen the part, improve its durability, and enhance its functional aspects. On the other hand, cosmetic finishes such as painting and clear coating are ideal for achieving a specific color, texture, or visual effect that aligns with your design vision.

Dealing with Layer Lines

One common challenge with 3D prints is the presence of layer lines, which are visible ridges or lines that result from the layer-by-layer printing process. These lines can negatively impact the visual appearance of the printed part. However, there are post-processing techniques that can minimize or eliminate the visibility of these layer lines, such as sanding or applying smoothing agents like epoxy or resin.

It’s important to experiment with different post-processing options and find the techniques that work best for your specific needs. By exploring the wide range of post-processing techniques offered by Stratasys, you can achieve the desired surface finish and enhance the quality of your 3D prints.

| Post-Processing Technique | Benefits |

|---|---|

| Media Blasting | Removes roughness and imperfections on the surface |

| Tumbling | Smoothes out the surface of the part |

| Bonding and Sealing | Strengthens the part and prevents material degradation |

| Sanding | Smooths out rough surfaces |

| Painting and Clear Coating | Enhances visual appearance with color and texture |

Material Selection for Stratasys 3D Printing

When it comes to 3D printing with a Stratasys printer, material selection is a critical aspect of achieving the desired results. Understanding your material needs and the available options is essential to ensure optimal performance and functionality in your 3D prints.

Stratasys offers a wide range of materials, including various thermoplastics, each with its own unique properties and benefits. From ABS and polycarbonate to high-performance materials like Ultem and Nylon, these thermoplastics offer different levels of strength, durability, and resistance to temperature and chemicals.

Choosing the right material depends on the specific requirements of your project. For example, if you need a part with excellent mechanical properties, ABS or Ultem might be the ideal choice. On the other hand, if you require transparency or resistance to chemicals, materials like polycarbonate or PPSF could be more suitable.

It’s essential to consider the specific applications of the part you are printing and select a material that aligns with those requirements. Stratasys provides material data sheets and testing information to help you make informed decisions. By understanding the material properties and benefits, you can confidently choose the right material for your Stratasys 3D printing project.

Summary

- Material selection is crucial for achieving desired results in Stratasys 3D printing.

- Stratasys offers a wide range of thermoplastics with different properties and benefits.

- Consider the specific applications of your part to choose the right material.

- Stratasys provides material data sheets and testing information for informed decisions.

Table: Stratasys 3D Printing Material Options

| Material | Properties | Benefits |

|---|---|---|

| ABS | Good mechanical properties, impact resistance | Cost-effective, versatile |

| Polycarbonate | High strength, transparency | Good chemical resistance |

| Ultem | Excellent mechanical properties, high heat resistance | Flame retardant, chemical resistance |

| Nylon | Tough, flexible | High impact resistance |

Choosing the right material for your Stratasys 3D printing project is essential. By understanding the material options and their suitability for different applications, you can make informed decisions and achieve the desired results in your 3D prints.

Consulting with Stratasys Experts

If you want to accelerate your learning process and gain expert advice on using Stratasys 3D printers, it is highly recommended to consult with the experts at Stratasys Direct Manufacturing. With their extensive experience and knowledge, they can guide you in selecting the right technology, optimizing your designs, and exploring the full potential of 3D printing.

Whether you are a beginner or an experienced user, consulting with Stratasys experts can provide valuable insights and solutions to enhance your project’s success. With access to project engineers and professional services, you can tap into a wealth of 3D printing knowledge and resources that can help you overcome challenges, improve efficiency, and achieve your desired outcomes.

By partnering with Stratasys Direct Manufacturing, you can benefit from their industry-leading expertise and leverage their cutting-edge technologies to bring your ideas to life. From design assistance to material selection, they offer comprehensive support throughout the 3D printing process. Their team of experts can assist you in optimizing your designs for better printability, suggesting the most suitable materials for your specific application, and providing guidance on post-processing techniques to achieve the desired finish and functionality.

Why Consult with Stratasys Experts?

- Access to project engineers and professional services

- Unparalleled knowledge and expertise in 3D printing

- Assistance in optimizing designs for printability

- Guidance on material selection for specific applications

- Expert advice on post-processing techniques

- Comprehensive support throughout the 3D printing process

When it comes to mastering the Stratasys 3D printer and achieving exceptional results, having access to expert advice and resources can make a significant difference. The Stratasys Direct Manufacturing team is dedicated to helping you unlock the full potential of 3D printing and achieve success in your projects. So why wait? Consult with Stratasys experts today and take your 3D printing journey to the next level.

Conclusion

Congratulations on completing this comprehensive guide to mastering the Stratasys 3D printer! By understanding the different applications, design considerations, material selection, and post-processing options, you are now well-equipped to unlock the full potential of this innovative technology.

With your newfound knowledge, you have the power to transform your ideas into reality with efficient 3D printing techniques. The Stratasys 3D printer mastery you have achieved will enable you to bring your designs to life in a faster and more cost-effective manner.

Embrace the possibilities of additive manufacturing and let your creativity soar. With the Stratasys 3D printer at your fingertips, you have the tools to innovate and create groundbreaking solutions in various industries.

Thank you for joining us on this 3D printing journey. We hope you continue to explore the exciting world of Stratasys 3D printing, pushing boundaries and unleashing your imagination.

FAQ

How do I export my CAD files as STL for Stratasys 3D printing?

To export your CAD files as STL, you need to go to the export function in your CAD software and select the STL file format. This will generate a file consisting of triangles that form the surface of your part, ready for 3D printing.

What design considerations should I keep in mind for Stratasys 3D printing?

When designing for Stratasys 3D printing, you should consider factors such as support structures for overhangs, resolution, build orientation, wall thickness, and part size. Each 3D printing technology has specific design guidelines that you need to follow to optimize the printing process and achieve better results.

What post-processing options are available for Stratasys 3D prints?

Stratasys offers a range of post-processing options, including media blasting, tumbling, bonding, sealing, sanding, painting, and clear coating. The choice of post-processing depends on the desired surface finish and the intended use of the part. These post-processing techniques can enhance the final appearance and functionality of your 3D printed parts.

How do I choose the right material for Stratasys 3D printing?

When selecting a material for Stratasys 3D printing, you should consider factors such as your project’s requirements, material properties, and specific application needs. Stratasys offers a wide range of materials, including engineering-grade thermoplastics, carbon fiber composites, and high-performance polymers, each with its own strengths and benefits.

Can I consult with experts at Stratasys for guidance on using their 3D printers?

Absolutely! Stratasys has a team of experts at Stratasys Direct Manufacturing who can provide expert advice on selecting the right technology, optimizing your designs, and exploring the full potential of 3D printing. They also offer resources such as whitepapers, case studies, and a blog to help expand your 3D printing knowledge.

How can mastering the Stratasys 3D printer benefit my projects?

By mastering the Stratasys 3D printer, you can unlock the potential for innovation in your projects. Efficient 3D printing techniques allow you to bring your designs to life in a faster and more cost-effective manner. With high-quality 3D printing and advanced additive manufacturing capabilities, you can create prototypes and final parts with precision and durability.