3D Printer Enclosure Trends: New Insights & Data

Originally posted on December 1, 2023 @ 5:23 pm

Our goal is to offer practical advice, thorough how-to guides, and honest reviews through our technology blog. Our content is extensively tested and researched, guaranteeing precise and dependable information for our readers.

In this article, we delve into the latest trends in 3D printer enclosures, offering you new insights and data. As the additive manufacturing industry continues to evolve, we explore the growing potential of 3D printing in various sectors such as aerospace, automotive, and medical. We also discuss the role of additive manufacturing in transforming workflows and supply chains, as well as the importance of data in this innovative field.

Key Takeaways:

- Increased adoption of additive manufacturing technologies due to disruptions in the supply chain caused by the pandemic.

- Material qualification and demand for higher performance materials are driving confidence in 3D printing.

- Sustainability challenges are being addressed, showcasing the industry’s alignment with modern times.

- Funding raised from investors is expected to accelerate M&A activity in 2022.

- Exciting start-ups are preparing to launch new resin-based technologies, unlocking new applications in the future of 3D printing.

Stay tuned as we explore these topics and more in detail. Let’s dive into the exciting world of 3D printing enclosures together!

The Future of 3D Printing in 2022

In 2022, the 3D printing industry is set to witness significant advancements and innovations that will shape its future. As companies strive to deliver on their promises to investors, market consolidation is expected, leading to major acquisitions and expansions of product offerings. This consolidation will bring together complementary technologies and expertise, resulting in a more streamlined and comprehensive ecosystem for 3D printing. Exciting start-ups are also on the horizon, preparing to launch new resin-based technologies that will unlock new applications and push the boundaries of what is possible.

One area that holds great potential for growth is the development of do-it-yourself (DIY) 3D printer enclosures. As more individuals and small businesses embrace 3D printing, the need for affordable and accessible enclosure solutions becomes crucial. DIY enclosures, which can be customized and assembled according to specific needs, offer an excellent option for those looking to protect their equipment and enhance the printing environment. These enclosures not only provide a controlled atmosphere but also act as a safety barrier, shielding users from potential hazards.

Furthermore, the availability of 3D printer enclosure kits empowers users to create their own enclosures with ease. These kits typically include all the necessary components and instructions, allowing users to quickly assemble and customize their enclosures. With a variety of design options and sizes available, individuals can tailor the enclosure to fit their specific printer and workspace requirements.

The future holds immense potential for 3D printing, with advancements in technology and materials opening up new possibilities for innovation and growth.

Despite the optimism surrounding the future of 3D printing, there are concerns that the current hype cycle may cool down in the second half of the year. As with any emerging technology, it is essential to manage expectations and address any potential challenges that may arise. However, the overall trajectory of the industry remains positive, with continued investment, market growth, and a strong focus on improving accessibility and usability for users of all levels of expertise.

| Key Trends | Key Insights |

|---|---|

| Market Consolidation | – Major acquisitions and expansions |

| New Resin-Based Technologies | – Unlocking new applications |

| DIY Enclosures | – Affordable and accessible solutions |

| Enclosure Kits | – Customizable and easy to assemble |

The Role of Additive Manufacturing in Transforming Workflows and Supply Chains

Additive manufacturing, also known as 3D printing, is revolutionizing manufacturing workflows and transforming supply chains in various industries. The adoption of additive manufacturing solutions is accelerating as organizations recognize the specific applications and benefits it offers. This technology enables the production of critical components at the point of assembly or care, eliminating the need for complicated supply chains and reducing logistical delays. The ability of additive manufacturing to enable mass customization is bringing significant value to industries like automotive, aerospace, semiconductor capital equipment, and healthcare.

One of the key advantages of additive manufacturing is its ability to streamline and optimize workflows, resulting in greater efficiency and cost savings. By utilizing 3D printing technology, organizations can produce parts and components on-demand, reducing inventory costs and eliminating the need for large-scale production runs. This flexibility is particularly valuable in industries where products require frequent design iterations and customization. Additionally, additive manufacturing allows for the production of complex geometries and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods.

“Additive manufacturing is revolutionizing manufacturing workflows and transforming supply chains in various industries.”

Furthermore, the advancements in materials used in additive manufacturing are contributing to the field of regenerative medicine. The ability to create biocompatible structures and tissue scaffolds using 3D printing technology opens up new possibilities for personalized medicine and tissue engineering. Researchers and medical professionals are exploring the potential of 3D-printed organs, implants, and medical devices that can be tailored to individual patients’ needs.

In conclusion, additive manufacturing is playing a crucial role in transforming manufacturing workflows and supply chains. It offers unique advantages such as on-demand production, mass customization, and the ability to create complex geometries. The use of additive manufacturing is expected to continue growing across various industries, driven by advancements in materials and the potential for personalized medicine. As organizations embrace this technology, they can optimize their workflows, reduce costs, and unlock new possibilities for innovation and customization.

The Growing Importance of Data in 3D Printing

Data plays a crucial role in 3D printing, as it enables organizations to optimize workflows, enable automation, and protect intellectual property. In an increasingly digital production environment, the ability to access and analyze data is essential for driving efficiency and innovation. To fully utilize the potential of 3D printing, companies need to connect data from different processes and levels, creating a unified system that streamlines operations.

“Data is the lifeblood of modern manufacturing. It allows businesses to make informed decisions, optimize processes, and ensure quality control,” says Mark Johnson, CEO of Print Chomp. “In the context of 3D printing, data is particularly important as it empowers manufacturers to leverage the full capabilities of additive manufacturing technologies.”

One of the key challenges in data utilization is the need for domain-specific knowledge. While data can provide valuable insights, it requires expertise to interpret and apply it effectively. Organizations need a deep understanding of their specific industry and manufacturing processes to optimize their production process and achieve the desired outcomes. This knowledge is crucial in ensuring that data-driven decisions align with the unique requirements of each organization.

Another critical aspect of data in 3D printing is the protection of intellectual property. As companies embrace additive manufacturing, they need to safeguard their part designs and printing processes from unauthorized access and replication. Secure AM software platforms that can connect to different systems and datasets play a crucial role in ensuring data protection and preventing intellectual property theft.

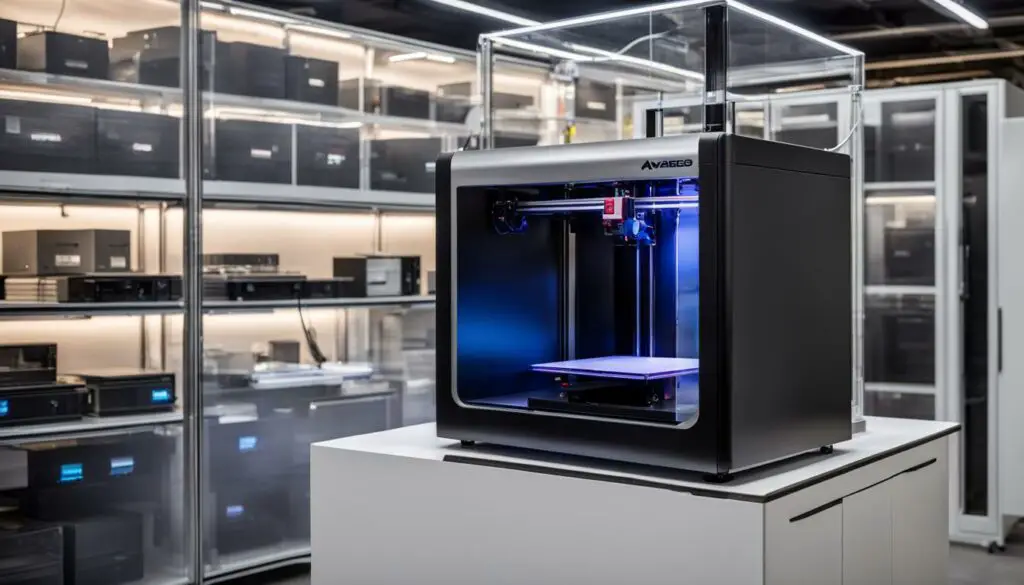

The Role of Data in Enclosed 3D Printers

When it comes to enclosed 3D printers, data becomes even more important for ensuring the safety and efficiency of the printing process. Enclosed 3D printers are designed to provide controlled environments that minimize the risk of external contaminants and temperature fluctuations. Data-driven features such as real-time monitoring of temperature, humidity, and ventilation help maintain optimal conditions for successful prints.

An enclosed 3D printer cabinet is an essential component of a fully enclosed setup. It provides additional protection and noise reduction, creating a controlled environment that enhances print quality. In combination with data-driven features, an enclosed 3D printer cabinet ensures consistent and reliable printing results.

| Key Benefits of Enclosed 3D Printers | Key Features of Enclosed 3D Printer Cabinets |

|---|---|

|

|

By integrating data-driven features with enclosed 3D printers and cabinets, manufacturers can achieve optimal printing conditions, leading to higher print success rates and improved overall efficiency. These advancements in data utilization and technology contribute to the ongoing growth and innovation in the field of 3D printing, enabling businesses to unlock the full potential of additive manufacturing.

Key Insights from the 3D Printing Market

The 3D printing market is experiencing significant growth, with businesses recognizing the value and potential of this innovative technology. Here are some key insights and trends shaping the industry:

Increased Adoption and Cost Savings

Businesses across various sectors are increasingly using 3D printing technology, with 71% reporting increased usage in 2022 compared to the previous year. The technology has enabled companies to save substantial costs in their manufacturing pipelines, with 83% of respondents acknowledging these savings. With 3D printing, companies can produce complex parts more efficiently, avoid expensive tooling, and reduce waste.

Popular Additive Technology: FDM

Among the different additive manufacturing technologies, Fused Deposition Modeling (FDM) is the most frequently used. Its accessibility and ease of use make it a popular choice for businesses of all sizes. FDM printers use thermoplastic materials to create 3D objects layer by layer, allowing for rapid prototyping and small-scale production. FDM technology offers a cost-effective solution for businesses looking to integrate 3D printing into their operations.

| 3D Printing Technology | Usage | |

|---|---|---|

| 1 | FDM | Most frequently used |

| 2 | Stereolithography (SLA) | High precision and quality |

| 3 | Selective Laser Sintering (SLS) | Diverse material options |

| 4 | Powder Bed Fusion (PBF) | Metal 3D printing |

3D Printing Covering Manufacturing Needs

For many businesses, 3D printing currently covers 0-20% of their overall manufacturing requirements. While it may not replace traditional manufacturing methods entirely, 3D printing is proving to be a valuable tool for prototyping, customization, and small production runs. As the technology continues to advance and new materials become available, the scope of 3D printing applications is expected to expand further.

These insights highlight the growing importance of 3D printing in various industries and the significant potential it offers for businesses. As the market continues to evolve, we can expect to see further advancements in technology, materials, and applications, opening up new possibilities for innovation and efficiency.

Regional Variations in 3D Printer Shipments

The second quarter of 2023 revealed interesting regional variations in the shipments of industrial 3D printers. Vendors in different parts of the world experienced contrasting patterns, highlighting the diverse dynamics and competition within the industry.

The Eastern region, especially China, saw significant year-on-year growth in industrial 3D printer shipments. This can be attributed to the region’s robust manufacturing ecosystem, which has embraced additive manufacturing technologies. Chinese vendors showcased their strength by introducing larger build models with multiple lasers, joining the “laser wars” as they strive to stay competitive.

On the other hand, Western vendors faced reduced capital expenditure in key end markets due to mergers and acquisitions. This impacted the shipments of industrial 3D printers in Western regions, such as North America and Western Europe. Despite these challenges, North America remained the second-largest market for industrial 3D printer shipments, followed by Western Europe.

It is worth noting that the growth of the industrial polymer segment was driven primarily by shipments in domestic China. This indicates the region’s strong focus on polymer-based additive manufacturing technologies. In the metal segment, powder bed fusion technology continued to dominate, showcasing its relevance and potential for various industries.

| Market | Industrial 3D Printer Shipments | |

|---|---|---|

| 1 | China | Largest market for industrial 3D printer shipments |

| 2 | North America | Second-largest market for industrial 3D printer shipments |

| 3 | Western Europe | Significant market for industrial 3D printer shipments |

In conclusion, regional variations in 3D printer shipments highlight the importance of different markets and the competitive landscape within the additive manufacturing industry. While China continues to dominate industrial 3D printer shipments, Western regions face challenges in capital expenditure. These insights shed light on the evolving dynamics of the 3D printing market and the ongoing quest for innovation and market share.

Conclusion

The future of 3D printing looks promising with continued growth and innovation. Market consolidation, the launch of new technologies, and the adoption of additive manufacturing in different industries are driving the industry forward.

Businesses are recognizing the value of 3D printing in transforming workflows and supply chains, with a focus on data utilization and protection. By connecting data from different processes and levels, organizations can optimize workflows, enable automation, and ensure the security of intellectual property.

The market is projected to continue growing, with increased usage and cost savings reported by businesses. As 3D printing becomes more widely adopted, companies are experiencing substantial savings in their manufacturing pipelines. Additionally, regional variations in 3D printer shipments highlight the importance of different markets and the competitive landscape.

Print Chomp, as a technology blog, provides practical tips, how-to guides, and unbiased reviews backed by rigorous testing and research. Stay tuned for more updates on the exciting developments in 3D printing!

FAQ

What are the potential sectors for growth in 3D printing?

Experts suggest that aerospace, automotive, and medical sectors have significant potential for growth in 3D printing.

What is driving the increased adoption of additive manufacturing technologies?

Disruptions in the supply chain caused by the pandemic, material qualification, and the demand for higher performance materials are driving the increased adoption of additive manufacturing technologies.

How is the 3D printing industry addressing sustainability challenges?

The 3D printing industry is addressing sustainability challenges, aligning with modern times and focusing on sustainable practices.

What is the expected impact of funding raised from investors on M&A activity in 2022?

Funding raised from investors is expected to accelerate M&A activity in the 3D printing industry in 2022.

What can we expect in terms of market consolidation in the 3D printing industry in 2022?

In 2022, the 3D printing industry is expected to witness market consolidation, with companies focusing on delivering on their promises to investors and announcing major acquisitions to expand their offerings.

Are there any exciting developments in resin-based technologies?

Exciting start-ups are preparing to launch new resin-based technologies that unlock new applications in 3D printing.

How is 3D printing transforming manufacturing workflows and supply chains?

3D printing, also known as additive manufacturing, is playing a critical role in transforming manufacturing workflows and supply chains by enabling the manufacture of critical components at the point of assembly or care, streamlining activities, and overcoming logistical delays.

Which industries are leveraging the mass customization capabilities of 3D printing?

Various industries, including automotive, aerospace, semiconductor capital equipment, and healthcare, are leveraging the mass customization capabilities of 3D printing.

What role does data play in 3D printing?

Data plays a crucial role in 3D printing, as a unified and increasingly digital production environment requires access to and analysis of data. Connecting data from different processes and levels optimizes workflows and enables automation.

How can organizations protect their intellectual property in 3D printing?

Organizations need to protect their intellectual property, both in terms of part designs and the printing process itself. AM software platforms that can connect to different systems and datasets are crucial for data utilization and protection.

What is the projected growth of the overall 3D printing market?

The overall 3D printing market is projected to grow by 17% and reach $19.9 billion in 2023.

How are businesses using 3D printing?

Businesses are increasingly using 3D printing, with 71% reporting increased usage in 2022 compared to the previous year. The technology has helped businesses save substantial costs in their manufacturing pipelines, with 83% of respondents acknowledging these savings.

What are the regional variations in 3D printer shipments?

The second quarter of 2023 saw contrasting patterns in the shipments of industrial 3D printers. Eastern vendors, especially in China, experienced strong year-on-year growth, while Western vendors faced reduced capital expenditure in key end markets due to mergers and acquisitions. China remained the largest market for industrial 3D printer shipments, followed by North America and Western Europe.