What is Printing and How it Works: The Ultimate Guide for Beginners

Originally posted on August 5, 2023 @ 9:21 am

What exactly is printing and how does it function? What is the definition of printing?

Well, glad you asked! Printing is like magic, turning digital art stuff into real prints! And have you heard about 3D printing? It’s even more incredible – making actual 3D objects!

If you’re interested in opening your own printing business but don’t know where to start, we’ve got your back!

We’ll guide you through the exciting journey of starting a printing business, but first, let’s learn more about printing and types of printing.

Printing Definition and Types of Printing Explained

Printing is making multiple copies of text or images on paper or other materials with a printing machine, also known as a printing press. Simply put, you duplicate what you see on a computer screen onto a physical piece of paper. And it’s a very lucrative business nowadays.

Printing types include:

1. Inkjet Printing

This type of printing works just like how you might use an inkjet printer at home. It sprays tiny ink droplets onto the paper to form the text or images. It’s great for color printing and everyday documents.

2. Laser Printing

Laser printing is also common in offices and homes. It uses a laser beam to create an electrostatic image on a drum, which attracts toner (a special kind of ink) and then transfers it onto the paper. It’s fast and suitable for text-heavy documents.

3. Offset Printing

This type of printing is a more professional and precise method for large quantities of prints, like books, magazines, and newspapers. It involves passing the inked image from a metal plate to the rubber blanket’s surface and then onto the paper publication printed for release.

4. Digital Printing

This type of printing is like a modern version of offset printing. It doesn’t use plates but directly transfers the desired image out from a computer to the printer. It’s great for small batches and personalized prints.

5. Screen Printing

Screen printing is a manual method of pushing ink through a mesh stencil onto the paper. It’s often used for making t-shirts, posters, and similar means of artwork.

6. Flexography

This type of printing is commonly used for packaging materials like bags and boxes. It uses flexible rubber plates to apply ink onto the paper or printed material.

7. Gravure Printing

Gravure printing is used for high-quality image reproduction in magazines and catalogs. It uses engraved cylinders to transfer ink onto the paper.

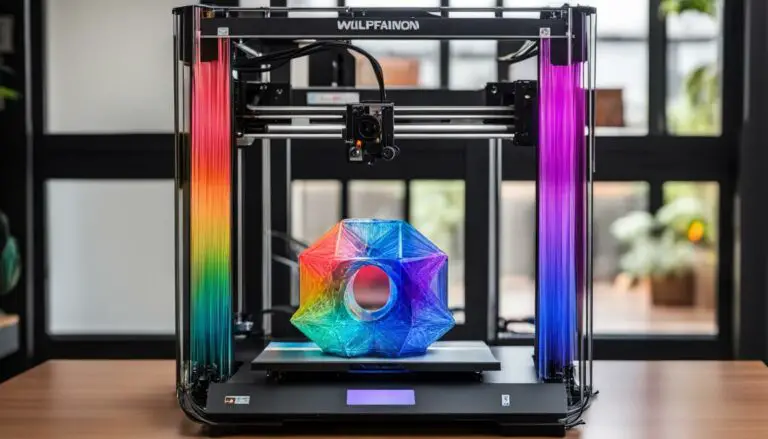

8. 3D Printing

This newer printing type creates three-dimensional objects layer by layer using materials like plastic, metal, or food!

9. Letterpress Printing

Letterpress printing is a form of relief printing. This word printing method makes words and pictures on paper by pressing inked metal letters and images onto the paper. It’s like using a stamp to create words and pictures on a piece of paper.

This method was commonly used in the past for producing books and newspapers before modern printers were invented. It gives a unique and classic look to printed materials.

Lastly, it’s not suitable for printing T-shirts. It was excellent for mass-reproducing text and typically paper-associated printing material.

10. Woodblock Printing (Old Printing Technique)

Woodblock printing creates pictures or patterns on paper or fabric using a carved piece of wood.

Imagine having a design carved out of wood like a stamp. You dip the carved wood into ink and press it onto the material basis. The ink on the raised wood block transfers onto the paper or fabric, making a printed image.

This type of printing played a key part in producing books, art, and decorations in the past.

Each way of producing printed material has pros and cons. So, whether you’re printing a school report, a family photo, a t-shirt design, or a book, there’s a printing method that’s just right for the job!

Which Printing is Best for T-Shirt?

When printing designs on t-shirts, you have a few options, but the best one depends on your needs and budget. Let’s break down the main methods:

1. Screen Printing

Screen printing is a popular choice for t-shirts, especially when you need to print many shirts with the same design.

It works well for simple and bold designs with limited colors. The setup cost can be a bit high, but the more shirts you print, the lower the cost per shirt becomes.

2. Direct-to-Garment (DTG) Printing

This type of printing is like using an inkjet printer, but instead of paper, it prints directly onto the t-shirt’s fabric. It’s great for small quantities or even one-off custom designs.

DTG can handle intricate and colorful designs with lots of details. However, it might not be as cost-effective for larger batches as screen printing.

3. Heat Transfer Printing

This type of printing involves the act of transferring a printed design from a special paper to a t-shirt using heat.

It suits small orders and works well for multi-color designs or photographs. However, the prints may not be as durable as those from screen printing or DTG.

4. Vinyl Printing (Heat Press Vinyl)

This method of cloth printing involves cutting designs and letters from vinyl sheets and then heat pressing them onto the t-shirt using a printing press.

It’s great for simple designs with solid colors, and it can give a nice, smooth finish. Vinyl printing is often used for sports team shirts and personalized names or numbers.

5. Sublimation Printing

Sublimation printing is ideal for polyester or polyester-blend shirts. It uses special inks that turn into gas when the material is heated, bonding with the fabric’s fibers.

It allows for vibrant, all-over prints but isn’t suitable for 100% cotton shirts.

6. Screen Printing + DTG Combo

Some companies use a combination of screen printing for the main design and DTG for smaller details or customizations. This hybrid approach can provide the best of both worlds regarding cost and versatility.

In summary, screen printing might be the best choice if you need many T-shirts with a simple design. DTG or heat transfer printing could be more suitable for small batches or highly detailed designs.

Consider your budget, the complexity of the design, and the fabric type to decide which printing method is the best fit for your t-shirt project!

Are Printing Businesses Profitable?

Well, it depends on a few things. First, a printing firm can do well if many people or companies need printing services in your area. But if not many people need it, it might be tough.

Versatility in the art process or business goals also matters, especially for your first printing business! Some businesses can do all kinds of printing, like flyers, posters, or even packaging. Producing printed material in various forms can attract more customers.

Having good machines and technology is essential. If the printing equipment is modern, it can save time and money, making the printing firm more profitable. But buying the equipment can be costly at first.

Quality and customer service also matter. If the printed matter looks great and the business treats customers well, people will return and recommend them to others.

Setting the right prices for your printed matter is a big deal. They need to be competitive but still make enough money to cover costs and earn a profit.

Marketing your printed matter is crucial too. Letting people know about the business through the Internet, social media, or community activity can bring in new customers.

Being efficient and not wasting materials is a smart way to save money. It’s also good for the environment.

Oh, and you must be ready for tough times in today’s modern knowledge-based economy.

Printing businesses may have fewer customers if the economy isn’t doing well. So, they must be ready for that and maybe focus on things people will always need.

So, if a printing business plans well, offers various services, has good machines, treats customers nicely, and keeps costs in check, it can be profitable.

This art process or business might take effort, but it can be a successful venture with the right approach!

Business of Producing Printed Material: How Much Does it Cost to Start a Printing Business?

Starting a printing business requires some money, but the cost can vary based on a few factors, such as the following:

1. Equipment Costs (Printing Press)

The most significant expense for this art process or business is usually the printing equipment. The price and costs can differ depending on the printing type you want.

Basic printing machines, like inkjet or laser printers, might be more affordable for small-scale businesses. But the machines can be more expensive if you think of professional printing, like offset or screen printing.

2. Location Costs

If you plan to have a physical store or workshop, you’ll need to consider the rent or purchase costs for the space. The location and size of the place can affect the overall expenses.

3. Materials and Supplies (Printed Material)

You’ll need paper, ink, toner, and other supplies to run the business. These costs can add up, especially if you’re doing large-scale printing.

4. Legal and Licensing Fees

Starting a business may involve paperwork and fees to get the necessary permits and licenses. These costs can vary depending on your location and the business structure you choose.

5. Marketing and Advertising

You should spend some money on marketing and advertising to attract customers. It could be flyers, online ads, or promoting your services in the community.

6. Insurance and Utilities

Don’t forget about insurance to protect your business and the utilities like electricity, water, and Internet needed to run the equipment.

7. Employee Costs

If you plan to hire employees, you must budget for their wages and any benefits you offer.

8. Contingency Funds

You should always have extra money for unexpected expenses or slow business periods.

So, the total cost to start a printing business can vary widely. For a small home-based operation, it might be a few thousand dollars; for a more significant commercial setup, it could be tens of thousands or even more.

It’s essential to research, create a budget, and figure out how much you can afford to invest.

How to Open a Printing Business: Step-by-Step Guide for Beginners

Starting a printing business can be exciting, but you must plan things out step-by-step. Here’s a simple guide to get you started:

Step 1: Research and Planning

Research to understand the local market and determine what type of printing services bring the most money. Decide what kind of printed form of printing you want to offer, like screen printing, digital printing, or others.

Create a business plan outlining your goals, target customers, pricing strategy, and financial projections.

Step 2: Legal Stuff

Choose a suitable business name and check if it’s available to register. Decide on a legal structure for your business (like sole proprietorship, partnership, or LLC).

Get the necessary permits, licenses, and tax identification numbers for your area.

Step 3: Location and Equipment

Determine if you’ll work from home or rent a separate space for your printing business.

Purchase the right printing equipment based on the type of printing you’ll be doing. Start with basic equipment and upgrade as your business grows.

Step 4: Supplies and Materials

Buy the necessary supplies like paper, ink, toner, and other materials required for your printing jobs.

Step 5: Setting Up Shop

Set up your workspace with the printing equipment and organize your supplies for easy access.

Step 6: Pricing and Services

Decide on your pricing strategy. Check what competitors charge and try to be competitive while making a profit.

Define your services, such as business cards, flyers, posters, or custom printing jobs.

Step 7: Marketing and Promotion

Create a simple website or social media page to showcase your services and reach potential customers.

Print business cards, printed letters, and flyers to distribute locally and let people know about your printing business. Network with local businesses and community events to get the word out.

Step 8: Customer Service

Provide excellent customer service to make people happy and likely to return or recommend your business to others.

Step 9: Start Small and Grow

Begin with small orders and gradually expand as you gain experience and build a customer base. You can also consider buying a used printing press. In fact, start with one printing press and buy more as you grow.

Step 10: Adapt and Improve

Keep track of what works and what doesn’t. Be open to adapting your services based on customer feedback and industry trends.

Continuously improve your printing skills and stay updated with new printing technologies.

Remember, starting a business takes time and effort, but with determination and a passion for printing, you can build a successful business step by step!

How Can I Improve My Printing Business: 15 Helpful Tips

Improving your printing business is about making smart changes and building on what works well. Here’s a list of simple steps to help you out:

1. Customer Feedback

Ask your customers for feedback about your services and listen to what they say. Their suggestions can help you identify areas for improvement.

2. Quality Matters

Focus on delivering high-quality prints and excellent customer service. Happy customers always come back and recommend your printing firm to others.

3. Upgrade Equipment

Consider investing in better printing equipment or software to enhance your printing jobs’ quality, speed, and efficiency. Consider buying a new printing press. Or invest in more than one printing press if you have many orders.

4. Diversify Services

Offer various printing services, such as business cards, brochures, banners, and custom prints. This can attract a broader range of customers.

5. Online Presence

Create a simple website or social media page to showcase your work and reach more potential customers. Online visibility can bring in new business.

6. Networking

Attend local business events or join community groups to network with potential clients and partners. Word-of-mouth referrals can be powerful.

7. Pricing Strategy

Review your pricing to ensure it’s competitive while allowing for a reasonable profit. Offer package deals or discounts for loyal customers.

8. Streamline Operations

Find ways to make your printing process smoother, reduce printing costs and waste, and save time and money when producing printed material.

9. Marketing Tactics

Experiment with marketing tactics, like online ads, flyers, or promotions. Keep track of what works best to focus your efforts.

10. Stay Updated

Keep up with printing industry trends and new technologies. Offering innovative solutions can set you apart from competitors.

11. Training and Skill Development

Invest in training for yourself and your employees to improve printing skills and stay updated with industry best practices.

12. Customer Loyalty Program

Consider implementing a customer loyalty program to reward repeat customers and encourage them to return.

13. Collaborations

Partner with local businesses or graphic designers to expand your reach and offer complementary services.

14. Feedback Loop

Continuously monitor the results of your improvements and adjustments. Use data and feedback to guide your ongoing efforts to enhance your business.

15. Stay Patient

Remember, improving a printing business is a gradual process. Don’t be afraid to try new things; be open to learning from successes and challenges.

With dedication and a commitment to excellence, your printing business can continue to grow and thrive!

Related Questions

Is Printing a Good Business?

Printing can be a good business if there’s enough demand for printing services in your area and you can offer high-quality prints at competitive prices. It’s essential to plan well, provide excellent customer service, and stay updated with industry trends to make it successful.

What is 3D Printing Business?

A 3D printing business involves creating three-dimensional objects using a special machine called a 3D printer. It’s a unique type of printing technology that allows you to make objects with different materials like plastic or metal.

What Do I Need to Start a 3D Printing Business?

To start a successful 3D printing business, you’ll need a 3D printer, printing materials (like plastic or metal filaments), a computer to design the objects you want to print, and some knowledge of 3D modeling software.

Can I Print Without a Computer?

Unfortunately, you can’t print without a computer; you need it to prepare the design files for printing on most printers, including 3D ones. The computer helps you create or download the 3D models and send them to the printer for production.

How to Print Without Computer?

If you don’t have a computer, you might be able to use a public computer or borrow one from a friend or family member. Some 3D printers have touchscreens and can be operated without a computer, but you’ll still need a digital file of the 3D model to transfer to the printer.

Business of Producing Printed Material: Final Thoughts

The business of producing printed material can be a great opportunity if there’s enough demand in your area and you can offer good quality prints at competitive prices.

Plan well, provide excellent customer service, and stay updated with industry trends.

For those interested in 3D printing, it’s a unique and exciting business idea. You’ll need a 3D printer, materials, a computer, and some 3D modeling knowledge to get your business started.

If you don’t have a computer, consider using a public computer or borrowing one.

Remember that most printers, including 3D printers, require a computer to prepare and send the printing instructions.

Overall, starting a printing business or a 3D printing venture can be rewarding with the right approach and dedication.

Good luck on your printing journey!