What is DTF Transfer

Originally posted on July 15, 2023 @ 4:06 pm

If the task of rewriting the following text is not feasible due to any challenges, please reply with the error message: Unable to process the request due to encountered difficulties.

DTF transfer, also referred to as Direct-to-Film transfer, is a widely utilized printing technique in the clothing industry for producing vibrant and top-notch designs on different types of fabrics. It presents a flexible and cost-efficient alternative to conventional printing methods. This article will delve into the concept of DTF transfer, its functioning, advantages, and its usefulness across various industries.

Understanding DTF Transfer

DTF transfer is a digital printing method that involves transferring designs directly from a special film to the fabric using heat and pressure. Unlike other printing methods, such as screen printing or heat transfer vinyl, DTF transfer allows for detailed and full-color prints with exceptional clarity and durability. It is suitable for both light and dark fabrics, including cotton, polyester, and blends.

Benefits of DTF Transfer

- Vibrant and Detailed Prints: DTF transfer enables the reproduction of intricate designs with vibrant colors and fine details. It offers excellent color saturation and allows for gradients, shadows, and complex patterns.

- Durability: The prints created through DTF transfer are highly durable and resistant to fading, cracking, and peeling. They can withstand multiple washes and maintain their quality over time.

- Versatility: DTF transfer can be applied to a wide range of fabrics, including t-shirts, hoodies, caps, bags, and more. It is suitable for both small-scale customization and large-scale production.

- Cost-Effectiveness: Compared to traditional printing methods, DTF transfer requires minimal setup and has lower production costs. It eliminates the need for screen preparation, making it an efficient and cost-effective solution.

How Does DTF Transfer Work?

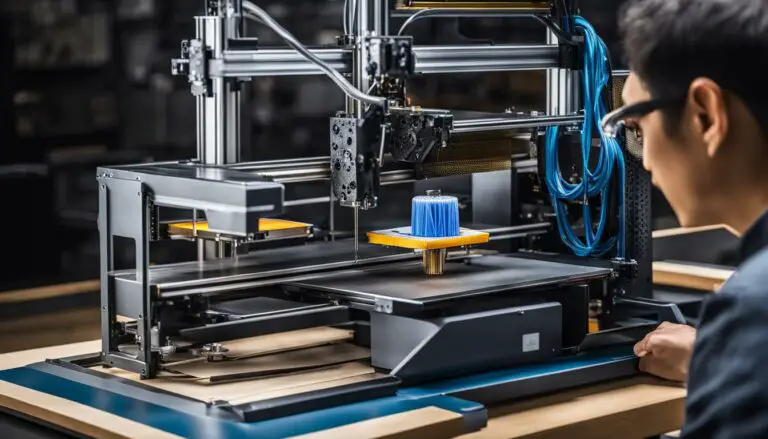

The DTF transfer process involves several steps:

- Design Preparation: The desired design is created or imported into specialized software. It is then printed onto a DTF film using a compatible printer.

- Film Transfer: The printed DTF film is placed onto the fabric, with the ink side facing down. Heat and pressure are applied using a heat press machine, allowing the ink to transfer from the film to the fabric.

- Peeling and Curing: After the transfer process, the film is carefully peeled off, leaving the printed design on the fabric. To ensure durability, the print is cured using a heat press or conveyor dryer.

Steps Involved in DTF Transfer Process

- Design creation or import into specialized software.

- Printing the design onto DTF film using a compatible printer.

- Placing the film onto the fabric and applying heat and pressure.

- Peeling off the film to reveal the transferred design.

- Curing the print for enhanced durability.

Equipment and Materials Required for DTF Transfer

To perform DTF transfer, you will need the following equipment and materials:

- DTF Printer: A printer specifically designed for DTF transfer, capable of printing high-quality designs onto the DTF film.

- DTF Film: Specialized film coated with a release layer that allows the ink to transfer onto the fabric. It should be compatible with your printer and suitable for the type of fabric you are working with.

- Heat Press Machine: A heat press machine is used to apply heat and pressure during the transfer process. It helps the ink adhere to the fabric effectively.

- Fabric: Various types of fabrics can be used for DTF transfer, such as cotton, polyester, or blends. Ensure that the fabric is clean, dry, and prepared for printing.

- Curing Equipment: Depending on the ink used, you may need a heat press or conveyor dryer to cure the print and ensure its long-lasting durability.

Tips for Successful DTF Transfer

To achieve optimal results with DTF transfer, consider the following tips:

- Choose High-Quality Films: Work with reputable suppliers and select DTF films that offer good adhesion and color vibrancy.

- Optimize Design Settings: Adjust the color profiles, resolution, and other settings in the design software to ensure accurate and vibrant prints.

- Preheat the Fabric: Before applying the film, preheat the fabric to remove any moisture and ensure proper ink adhesion.

- Test Prints: Always perform test prints on scrap fabric before transferring onto the final product. This helps identify any issues and fine-tune the printing parameters.

- Follow Manufacturer Instructions: Adhere to the recommended temperature, pressure, and time settings provided by the DTF film and ink manufacturers.

Common Challenges in DTF Transfer

While DTF transfer offers numerous advantages, there can be some challenges. Here are a few common ones:

- Film Adhesion Issues: Improper adhesion of the DTF film to the fabric can result in incomplete transfers or peeling of the print.

- Color Fidelity: Achieving accurate color reproduction can be challenging due to variations in printer settings, fabric types, and design complexities.

- Film Storage and Handling: DTF films are sensitive to environmental factors such as temperature and humidity. Proper storage and handling are essential to maintain their quality.

- Learning Curve: Mastering DTF transfer techniques may require some practice and experimentation to achieve consistent and high-quality results.

Best Practices for DTF Transfer

Follow these best practices to optimize your DTF transfer process:

- Quality Control: Regularly check the output prints for any defects or inconsistencies. Implement quality control measures to ensure customer satisfaction.

- Stay Updated: Keep up with the latest advancements in DTF transfer technology, equipment, and materials to enhance your printing capabilities.

- Explore Design Possibilities: Experiment with different designs, color combinations, and effects to offer unique and eye-catching prints to your customers.

- Offer Customization: Capitalize on the versatility of DTF transfer by offering personalized and customized designs to cater to individual preferences.

DTF Transfer vs. Other Printing Methods

DTF transfer has several advantages over other printing methods:

- Higher Color Vibrancy: DTF transfer allows for more vibrant and detailed prints compared to traditional screen printing or heat transfer vinyl.

- No Color Limitations: Unlike screen printing, DTF transfer does not have color limitations or additional setup costs for each color used in the design.

- Lower Setup Costs: DTF transfer eliminates the need for screen preparation or cutting vinyl, making it a cost-effective option for both small-scale and large-scale production.

- Print Complexity: DTF transfer enables the reproduction of complex designs with gradients, shadows, and fine details, which can be challenging with other methods.

Applications of DTF Transfer

DTF transfer finds applications in various industries, including:

- Sports and Team Uniforms: DTF transfer allows sports teams to customize their uniforms with vibrant logos, player numbers, and team names.

- Promotional Merchandise: DTF transfer can be used to create customized promotional items such as t-shirts, hats, bags, and accessories for events, trade shows, and marketing campaigns.

- Corporate Branding: DTF transfer enables businesses to print their logos, slogans, and branding elements on employee uniforms, company merchandise, and promotional materials.

- Fashion Accessories: DTF transfer can be applied to various fashion accessories like hats, scarves, socks, and shoes, adding unique designs and personalization.

- Home Decor: DTF transfer allows for the creation of custom-designed pillows, curtains, tablecloths, and other fabric-based home decor items.

- Arts and Crafts: DTF transfer is popular among artists and crafters for creating unique designs on fabric-based art pieces, quilts, and handmade crafts.

- Children’s Clothing: DTF transfer provides a fun and creative way to customize children’s clothing with colorful prints, characters, and patterns.

Future of DTF Transfer

The future of DTF transfer looks promising, with advancements in technology and materials continuously improving the printing process. Some potential developments include:

- Improved Ink Formulations: Research and development efforts are focused on creating inks that offer even better color vibrancy, durability, and washability.

- Enhanced Printing Speed: The printing speed of DTF transfer systems is expected to increase, allowing for faster production and shorter turnaround times.

- Expansion into New Markets: DTF transfer is likely to expand its presence in industries such as interior design, automotive, and medical textiles, where customization and high-quality prints are in demand.

- Integration with E-commerce: The integration of DTF transfer technology with e-commerce platforms will enable businesses to offer on-demand customization options to customers worldwide.

Conclusion

DTF transfer is a versatile and cost-effective digital printing method that offers vibrant, detailed, and durable prints on various fabrics. With its numerous benefits, including high color vibrancy, versatility, and cost-effectiveness, DTF transfer has gained popularity in industries such as fashion, sports, promotional merchandise, and home decor. As technology continues to advance, the future of DTF transfer holds even more exciting possibilities for customization and high-quality printing.

FAQs

1. Is DTF transfer suitable for all fabric types? Yes, DTF transfer can be used on a wide range of fabric types, including cotton, polyester, and blends.

2. Can I wash garments printed with DTF transfer? Yes, garments printed with DTF transfer are washable and can withstand multiple washes without fading or peeling.

3. Can DTF transfer be used for small-scale customization? Absolutely! DTF transfer is suitable for both small-scale customization and large-scale production.

4. How long does the DTF transfer process take? The time required for DTF transfer depends on factors such as design complexity, equipment, and the number of items being printed. It typically takes a few minutes per print.

5. Where can I get access to DTF transfer equipment and materials? You can find DTF transfer equipment and materials from specialized suppliers and manufacturers.