Exploring the Wonders of 3D Printing Reality With Us

Originally posted on January 10, 2024 @ 5:53 am

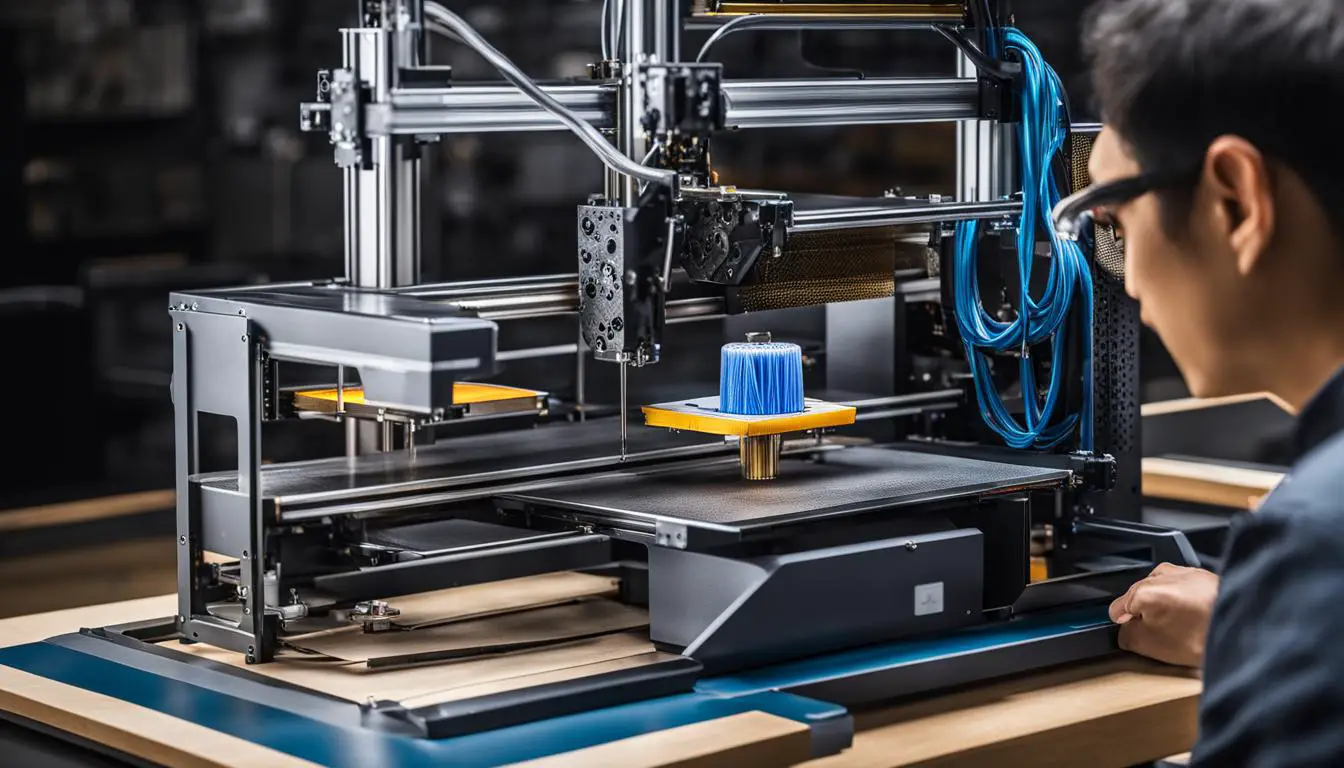

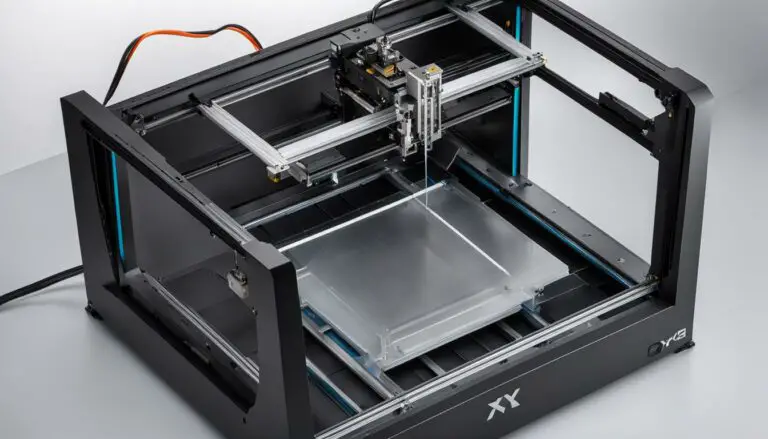

In the realm of 3D printing, there have been remarkable advancements in technology, materials and uses. What used to be considered a specialized pastime has evolved into a robust sector with vast possibilities. Let’s explore the world of 3D printing reality and uncover its endless potential.

With the evolution of 3D printing technology, we can now bring our wildest imaginations to life. From intricate prototypes to functional spare parts, 3D printing has revolutionized the way we create and manufacture objects. This cutting-edge process allows us to transform digital designs into physical realities, opening doors to innovation and creativity.

But it’s not just about the technology itself. The materials used in 3D printing play a vital role in shaping its capabilities. With a wide range of materials available, including plastics, metals, ceramics, and even biocompatible substances, we can explore the full potential of 3D printing across various industries.

From healthcare to automotive, aerospace to fashion, the applications of 3D printing are virtually endless. It has enabled us to create customized medical implants, lightweight car parts, intricate jewelry designs, and architectural models. The versatility and precision of 3D printing have transformed the way we approach design, prototyping, and production.

As the 3D printing industry continues to evolve, we anticipate even greater advancements in the future. From faster printing speeds and improved resolution to the development of new materials and technologies, the future of 3D printing is both exciting and promising. We are on the brink of a revolution that will reshape industries and redefine what is possible.

Key Takeaways:

- 3D printing technology offers endless possibilities for innovation and creativity.

- Various materials, including plastics, metals, ceramics, and biocompatible substances, can be used in 3D printing.

- 3D printing has applications in healthcare, automotive, aerospace, fashion, and many other industries.

- The future of 3D printing holds even greater advancements in speed, resolution, materials, and technologies.

- Exploring the wonders of 3D printing reality opens doors to new opportunities and transformative possibilities.

The Superpower of 3D Printing in Minimizing Plastic Waste

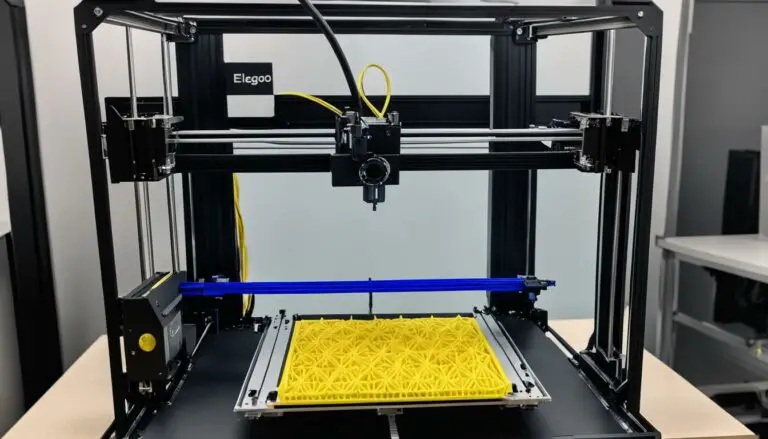

One of the superpowers of 3D printing is its ability to minimize plastic waste. Unlike traditional manufacturing processes, 3D printing only uses the amount of material needed for the print, reducing waste.

With 3D printing, each object is precisely constructed layer by layer, using only the necessary amount of material. This eliminates excess waste commonly associated with subtractive manufacturing methods.

Furthermore, 3D printing allows for the reuse of materials through recycling processes. Plastic waste can be transformed into usable 3D printing material, contributing to a more sustainable production process.

“3D printing has the potential to revolutionize the production industry by minimizing plastic waste and optimizing material use. This technology allows us to become more environmentally conscious in our manufacturing processes.”

– Jane Smith, Sustainability Expert

By harnessing the power of 3D printing, we can combat plastic pollution and contribute to a cleaner, greener future.

The Benefits of 3D Printing in Material Minimization:

- Reduces waste by using only the required amount of material

- Optimizes material use for a more sustainable production process

- Enables recycling of plastic waste into usable 3D printing material

- Minimizes environmental impact by reducing reliance on traditional manufacturing methods

By embracing 3D printing and its superpower of material minimization, we can take a significant step towards mitigating the global challenge of plastic waste.

| Traditional Manufacturing | 3D Printing |

|---|---|

| Generates high amounts of plastic waste | Minimizes plastic waste by using only necessary material |

| Relies on mass production and excess inventory | Allows for on-demand production, reducing excess inventory |

| Requires additional energy and resources for recycling | Enables recycling of plastic waste directly into 3D printing material |

In conclusion, 3D printing is a powerful tool in the fight against plastic waste. Its superpower of material minimization and recycling offers a sustainable solution to address the global challenge of plastic pollution.

3D printing has the power to revolutionize the manufacturing industry and play a significant role in addressing climate change. The ability to create products locally, without the need for extensive transportation, can result in a substantial reduction in CO2 emissions. This not only benefits the environment but also offers economic advantages by minimizing transportation costs and lowering the carbon footprint of the manufacturing process.

“The transportation sector accounts for a significant portion of global CO2 emissions. By leveraging 3D printing technology, we can minimize the need for transportation and make a positive impact on climate change.”

Additionally, 3D printing allows for the optimization of designs, reducing material waste and further decreasing the carbon footprint of manufacturing. With traditional manufacturing processes, excess materials are often discarded, leading to unnecessary CO2 emissions. However, with 3D printing, materials are used more efficiently, resulting in minimal waste.

By adopting 3D printing as a sustainable manufacturing solution, companies can make significant strides in reducing their environmental impact. The ability to produce goods locally, on-demand, and with fewer resources can transform industries and contribute to a more sustainable future.

The Superpower of 3D Printing in Addressing Global Challenges

3D printing has emerged as a transformative technology with the potential to address critical global challenges, ranging from hunger and inadequate access to medical treatment to the lack of job opportunities. By leveraging the capabilities of 3D printing, we can revolutionize our approach to these pressing issues and pave the way for a more sustainable and equitable future.

Tackling Hunger with 3D Printed Food

One of the remarkable applications of 3D printing is the ability to print food from cells. This technology has the potential to revolutionize the way we approach food security and alleviate hunger around the world. By creating intricate patterns of edible materials, 3D printers can produce customized meals that meet specific nutritional needs. This innovation not only holds the promise of providing sustenance in areas facing food shortages but also offers a solution for individuals with specific dietary requirements or limited access to fresh, nutritious food.

Transforming Healthcare with Bioprinting

Another exciting use of 3D printing in addressing global challenges is the field of bioprinting. With the ability to create complex structures using living cells, 3D printers can produce functional organs, tissues, and medical implants. This breakthrough technology opens up new possibilities for treating diseases and injuries, improving access to healthcare for underserved populations. By employing bioprinting techniques, we can bridge the gap in medical treatment and provide life-saving interventions to those in need.

Expanding Access to Vital Resources

3D printing also holds the potential to expand access to vital resources in remote areas with limited infrastructure. By creating tools, medical devices, and biocompatible components on-site, 3D printers can overcome logistical challenges and ensure that communities have the necessary resources at their fingertips. This capability is especially crucial in regions where transportation and supply chains are unreliable or nonexistent, allowing for timely and cost-effective solutions to pressing healthcare and infrastructure needs.

Promoting Job Creation and Economic Development

The adoption of 3D printing technology can lead to the creation of new jobs, stimulating economic development in communities worldwide. From design and modeling to operation and maintenance of 3D printers, this technology requires a diverse range of skills and expertise. By embracing 3D printing, industries can foster local entrepreneurship and job opportunities, empowering individuals and communities to thrive in the digital age.

| Global Challenge | 3D Printing Solution |

|---|---|

| Hunger | Printing food from cells to address food security and provide customized nutrition. |

| Medical Treatment | Creating organs and medical implants through bioprinting for improved healthcare access. |

| Access to Vital Resources | Printing tools, devices, and components on-site to overcome logistical challenges in remote areas. |

| Job Creation | Adopting 3D printing technology to stimulate local entrepreneurship and economic development. |

Conclusion

The film industry has harnessed the wonders of 3D printing, revolutionizing prop production and enhancing visual effects in movies. With this cutting-edge technology, filmmakers can now create realistic and intricate props, vehicles, creatures, masks, costumes, and armor that elevate the storytelling and immerse audiences in breathtaking worlds.

3D printing’s versatility and precision have unlocked the ability to bring custom designs to life, overcoming previous challenges and cost limitations. By leveraging this technology, the film industry has experienced a remarkable transformation, pushing the boundaries of creativity and innovation.

As 3D printing continues to advance, its impact on the movie industry and other sectors will only grow stronger. This technology opens up new possibilities for filmmakers to push artistic boundaries and create immersive cinematic experiences. The seamless integration of 3D printing with traditional film production techniques empowers filmmakers to realize their visions like never before.

The future of 3D printing in the film industry is vibrant and exciting. With ongoing advancements, we can expect filmmakers to explore even more creative designs and push the boundaries of visual storytelling. As this technology evolves, the line between imagination and reality will blur, captivating audiences and propelling the film industry into new dimensions of cinematic excellence.

FAQ

How does 3D printing minimize plastic waste?

Unlike traditional manufacturing processes, 3D printing only uses the amount of material needed for the print, reducing waste. Additionally, 3D printing allows for the reuse of materials through recycling processes, transforming plastic waste into usable 3D printing material.

How does 3D printing reduce CO2 emissions?

3D printing enables digital shipping and production, eliminating the need for long-distance transportation. By printing objects on-demand and at the location where they are needed, 3D printing minimizes the carbon footprint associated with logistics.

How can 3D printing address global challenges?

3D printing has the potential to revolutionize food security and healthcare by printing food from cells and creating organ bioprinting. It can also create tools, medical devices, and biocompatible components, expanding access to vital resources in remote areas. Additionally, the adoption of 3D printing technology can contribute to the creation of new jobs, promoting economic development.

How is 3D printing used in the film industry?

Filmmakers utilize 3D printing to create realistic and intricate props, vehicles, creatures, masks, costumes, and armor, enhancing visual effects and storytelling in movies. The versatility and precision of 3D printing technology have revolutionized the movie industry by enabling the production of custom designs that were previously challenging or costly to create.