DTF vs Sublimation: Understanding the Differences

Originally posted on July 15, 2023 @ 3:10 pm

When it concerns printing options for personalized apparel and fabric goods, two commonly used methods are DTF (Direct-to-Film) and Sublimation. These methods have distinct benefits and characteristics. In this article, we will examine DTF and Sublimation printing, discussing their processes, comparing their attributes, and assisting you in selecting the ideal method for your particular requirements.

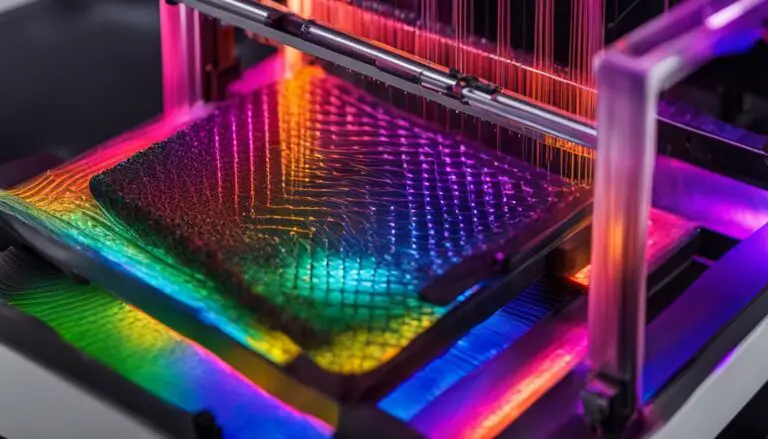

1. What is DTF?

DTF stands for Direct-to-Film and is a printing technique that involves printing designs directly onto a specialized film, which is then transferred onto the fabric using heat and pressure. DTF printing has gained popularity in recent years due to its versatility and ability to achieve vibrant and detailed prints on various fabrics.

The Process of DTF Printing

- Design Creation: The first step in DTF printing is creating or selecting a design that you want to print on the fabric.

- Printing onto Film: The design is printed onto a specialized film using a DTF printer and specially formulated inks.

- Heat Transfer: The printed film is placed onto the fabric, and heat is applied using a heat press machine. The heat activates the adhesive layer on the film, allowing it to bond with the fabric fibers.

- Peeling and Finishing: After the heat transfer process, the film is peeled off, leaving behind a vibrant and durable print on the fabric.

2. What is Sublimation?

Sublimation is a printing technique that involves transferring ink onto a substrate (such as fabric) using heat. The ink used in sublimation printing is specially formulated to convert from a solid to a gas without going through a liquid stage. This unique characteristic allows the ink to penetrate the fabric and create permanent, high-quality prints.

The Process of Sublimation Printing

- Design Creation: Similar to DTF printing, the first step in sublimation printing is designing or selecting the artwork that will be transferred onto the fabric.

- Printing onto Transfer Paper: The design is printed onto a special transfer paper using sublimation inks.

- Heat Transfer: The printed transfer paper is placed onto the fabric, and heat is applied using a heat press machine. The heat causes the ink to sublimate, turning it into a gas that permeates the fabric fibers.

- Cooling and Finishing: After the heat transfer process, the fabric is allowed to cool down, and the transferred ink solidifies, resulting in a vibrant and durable print.

3. Comparison of DTF and Sublimation

Now let’s compare DTF and Sublimation printing methods based on different factors to help you make an informed decision.

Print Quality and Durability

Both DTF and Sublimation offer excellent print quality and durability. However, DTF printing has an advantage when it comes to achieving higher levels of detail and sharpness, making it ideal for intricate designs and complex artwork. Sublimation, on the other hand, provides vibrant colors and good durability, making it suitable for a wide range of applications.

Color Vibrancy

Sublimation printing is known for its exceptional color vibrancy. The process allows the ink to permeate the fabric fibers, resulting in prints that are vivid, long-lasting, and resistant to fading. DTF printing also produces vibrant colors but may not offer the same level of color vibrancy as sublimation.

Fabric Compatibility

DTF printing works well on various types of fabrics, including cotton, polyester, blends, and even leather. It provides good adhesion and flexibility on different materials. Sublimation printing, on the other hand, is most suitable for polyester-based fabrics. The ink used in sublimation bonds exceptionally well with polyester fibers, resulting in vibrant and permanent prints.

Complexity and Equipment Required

DTF printing requires specialized equipment, including a DTF printer, heat press machine, and DTF film. The process can be relatively straightforward once the equipment is set up correctly. Sublimation printing also requires specific equipment, such as a sublimation printer, heat press machine, and sublimation inks. However, the process may involve additional steps, such as coating the fabric with a sublimation-friendly layer.

5. Pros and Cons of DTF Printing

Advantages of DTF Printing

- High level of detail and sharpness

- Good adhesion on various fabrics

- No special coating required for the fabric

Disadvantages of DTF Printing

- Limited color vibrancy compared to sublimation

- Requires additional steps for white ink printing

- Relatively new printing technique, limited availability

6. Pros and Cons of Sublimation Printing

Advantages of Sublimation Printing

- Exceptional color vibrancy and durability

- Suitable for a wide range of polyester-based fabrics

- Large color gamut, allowing for accurate color reproduction

Disadvantages of Sublimation Printing

- Limited compatibility with non-polyester fabrics

- Requires a sublimation-friendly coating on the fabric

- Can be challenging to achieve intricate details

Conclusion

In summary, both DTF and Sublimation printing offer unique advantages and are suitable for different applications. DTF printing provides high levels of detail and works well on various fabrics, while Sublimation printing excels in color vibrancy and is best suited for polyester-based fabrics. Consider your specific requirements and the desired outcome when choosing between these two printing methods.

Frequently Asked Questions (FAQs)

- Can I use DTF printing on cotton fabrics?

- Yes, DTF printing can be used on cotton fabrics. However, the print results may vary compared to polyester-based fabrics.

- Is sublimation printing suitable for dark-colored fabrics?

- Sublimation printing works best on light-colored or white polyester-based fabrics. It is not recommended for dark-colored fabrics due to the limitations of the sublimation process.

- Which printing method is more cost-effective?

- The cost-effectiveness of each method depends on various factors such as the volume of printing, complexity of the designs, and availability of equipment and materials. It’s best to evaluate your specific requirements and consult with a professional to determine the most cost-effective option.