Discover the Versatility of 3D Inkjet Printers for Your Needs

Originally posted on November 17, 2023 @ 1:32 pm

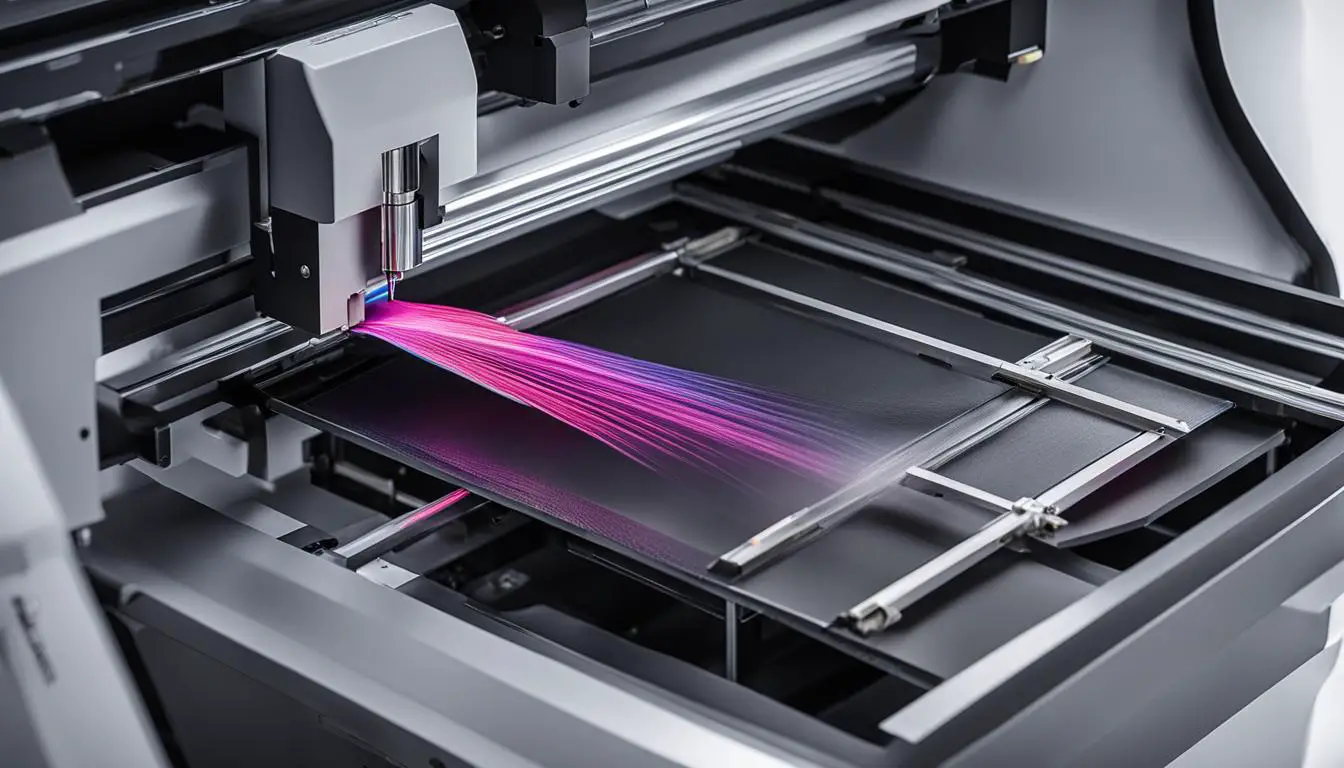

The introduction of 3D inkjet printers has greatly transformed the field of additive manufacturing by providing numerous benefits for different purposes. From producing complex 3D printed items to printing electronics, inkjet printer technology guarantees superior precision, polished surface texture, and a fast production process, making it the ideal option for your requirements.

When comparing 3D inkjet printers, it’s important to consider factors such as material limitations and mechanical strength requirements. While there are desktop-scale options available, enterprise-scale printers may require additional steps such as sintering for metals or ceramics.

Key Takeaways:

- 3D inkjet printers offer advantages such as high resolution and smooth surface finish.

- They are suitable for additive manufacturing of PCBs and 3D printing circuitry.

- Material limitations and mechanical strength requirements should be considered for specific applications.

- Desktop-scale printers are available, but enterprise-scale printers may require additional steps.

- Inkjet deposition simplifies the workflow and reduces manufacturing steps.

How Inkjet Printing Revolutionizes PCB Manufacturing

Inkjet printing is a unique process for 3D printing PCBs (printed circuit boards) that offers numerous advantages. Unlike traditional fabrication methods, inkjet printing allows for the precise deposition of conductive and insulating materials using multiple printheads and a layer-by-layer approach. The high resolution of 3D inkjet printing results in smooth surface finishes, making it possible to print microstrip and stripline traces that match those of traditional PCBs.

One of the key benefits of inkjet printing in PCB manufacturing is its versatility. While there may be limitations in material range, inkjet printing is suitable for a wide range of electronics applications. The use of conductive nanoparticle inks, for example, eliminates the need for a high-temperature oven, as the inks can be sintered with an infrared lamp. However, it is important to note that 3D-printed parts may have lower mechanical strength compared to traditionally manufactured boards.

Overall, inkjet printing revolutionizes PCB manufacturing by providing a digital manufacturing technology that offers high resolution, smooth surface finishes, and the ability to print complex geometries and intricate details. Although there are limitations to consider, inkjet printing offers a versatile and cost-effective solution for electronics manufacturing.

The Advantages of Inkjet Printing for PCB Manufacturing:

- Precise deposition of conductive and insulating materials

- High resolution for smooth surface finishes

- Versatility for a wide range of electronics applications

- Ability to print complex geometries and intricate details

- Cost-effective solution for PCB manufacturing

| Inkjet Printing | Traditional PCB Manufacturing |

|---|---|

| Precise deposition of materials | Requires etching or drilling |

| High resolution and smooth surface finishes | Dependent on manufacturing process and materials |

| Versatile for a wide range of electronics applications | May require multiple processes for different applications |

| Ability to print complex geometries and intricate details | Limitations in design freedom |

| Cost-effective solution | Higher cost for prototyping and manufacturing |

By leveraging the advantages of inkjet printing, PCB manufacturers can streamline their production process, reduce costs, and create high-quality, customized PCBs for a variety of electronics applications.

The Advantages of Inkjet Printing for Electronics Manufacturing

Inkjet printing offers several advantages for electronics manufacturing. With the ability to deposit a range of materials at low viscosities, inkjet systems can print conductive and insulating materials with high resolution and surface finish. The layer-by-layer deposition allows for the printing of large areas and the simultaneous deposition of multiple materials, making it ideal for additive manufacturing of PCBs. While there are limitations on the range of materials that can be used, such as viscosity requirements, advancements in conductive and insulating materials are expected to expand the capabilities of 3D inkjet printing. Inkjet printing also offers a simplified workflow with reduced manufacturing steps and predictable costs.

Inkjet Printer Features

When considering inkjet printers for electronics manufacturing, there are several key features to look for:

- Resolution: A higher resolution allows for finer details and more precise printing, resulting in better performance and functionality of the printed electronics.

- Material Compatibility: Ensure that the printer is compatible with the specific conductive and insulating materials required for your application.

- Print Speed: A faster print speed increases productivity and efficiency in the manufacturing process, reducing lead times.

- Multiple Printhead System: An inkjet printer with multiple printheads allows for the simultaneous deposition of multiple materials, enabling the creation of complex electronic circuits.

- Software Compatibility: Choose a printer that is compatible with the software used for designing and preparing the 3D models, ensuring a seamless workflow.

By considering these features, you can select an inkjet printer that meets your specific requirements for electronics manufacturing.

Table: Top 3D Printer Brands for Electronics Manufacturing

| Brand | Resolution | Material Compatibility | Print Speed | Multiple Printhead System | Software Compatibility |

|---|---|---|---|---|---|

| Brand A | High | Wide range | Fast | Yes | Compatible |

| Brand B | Medium | Selected materials | Medium | No | Compatible |

| Brand C | High | Wide range | Slow | Yes | Compatible |

Table: Comparison of top 3D printer brands for electronics manufacturing. Brand A offers high resolution, fast print speed, and compatibility with a wide range of materials. Brand B has medium resolution and print speed with limited material compatibility. Brand C provides high resolution but slower print speed, with compatibility for a wide range of materials.

Understanding the Process of 3D Inkjet Printing

3D inkjet printing is a fascinating technology that allows for the creation of intricate 3D printed objects. The process involves the deposition of liquid materials or solid suspensions in a layer-by-layer fashion. The materials, such as polymers, dielectric nanoparticles, and conductive nanoparticles, are extruded through a small nozzle within a print head. As the print head moves over the surface, multiple layers are built up and cured with UV lamps.

One of the key advantages of inkjet printing is its ability to print complex geometries and intricate details. This opens up a world of limitless design possibilities. Whether it’s creating intricate jewelry, customized prototypes, or functional parts, inkjet printing offers versatility like no other manufacturing technology.

The cost structure of 3D inkjet printing is primarily determined by the weight of the material used and the energy consumed during deposition. This makes it a cost-effective solution for small-scale production or rapid prototyping. Additionally, the layer-by-layer deposition process allows for quick curing times, resulting in faster production cycles.

| Advantages of 3D Inkjet Printing | Limitations of 3D Inkjet Printing |

|---|---|

| Ability to print complex geometries | Limited range of printable materials |

| Intricate details and high resolution | Lower mechanical strength compared to traditional manufacturing |

| Quick curing times | Material and energy cost |

In conclusion, 3D inkjet printing is a powerful technology that opens up a world of possibilities for designers, engineers, and manufacturers. Its ability to create complex geometries, intricate details, and quick curing times make it a versatile and cost-effective solution. While there are limitations in terms of printable materials and mechanical strength, advancements in materials science are constantly pushing the boundaries of what is possible with 3D inkjet printing.

PolyJet Technology: Transforming 3D Printing

PolyJet technology is a game-changer in the world of 3D printing. With its multi-material jetting photopolymer 3D printing capabilities, it revolutionizes the way objects are created. This technology allows for the production of complex geometries, intricate details, and even full-color combinations in a single model. From automotive parts to healthcare devices, architecture models to consumer goods, PolyJet has found its place in various industries, driving advancements and innovation.

One of the key strengths of PolyJet technology lies in its versatility. It enables the printing of objects with different materials, both rigid and flexible, in a single print. This opens up endless possibilities for creative design and functional prototypes. Plus, with the ability to generate a wide range of colors and finishes, PolyJet offers stunning visual appeal for both prototypes and end-use parts.

Stratasys, a leading provider of 3D printing solutions, offers a range of PolyJet printers to cater to diverse industries and applications. Whether you’re in automotive manufacturing, healthcare research, or architectural design, there’s a PolyJet printer that meets your specific needs. With its exceptional precision, versatility, and ability to bring ideas to life, PolyJet technology is transforming the world of 3D printing.

Conclusion

Inkjet printing has revolutionized the world of additive manufacturing, particularly in the field of electronics and PCB manufacturing. The versatility of 3D inkjet printers allows for the creation of complex and intricate 3D printed objects, thanks to high resolution and the ability to deposit multiple materials simultaneously. This inkjet printer technology offers a wide range of applications in various industries, driving advancements in 3D printing technology.

While there are limitations in terms of material range and mechanical strength, the continuous development of conductive and insulating materials is expected to overcome these challenges. With the potential for creating fully functional and visually stunning prototypes and end-use parts, inkjet printing is at the forefront of innovation in additive manufacturing. The future of 3D inkjet printers holds great promise, as advancements in technology continue to push the boundaries of what is possible.

One notable advancement in inkjet printing technology is PolyJet, which takes 3D printing to a whole new level. With its precision and versatility, PolyJet allows for the creation of complex geometries, intricate details, and full-color combinations. This technology has found applications in industries such as automotive, healthcare, architecture, and consumer goods, driving further advancements in aerodynamics, customization, and patient-specific models.

As the demand for 3D inkjet printers continues to grow, the future of additive manufacturing looks promising. These printers provide a powerful tool for designers, engineers, and manufacturers to bring their ideas to life. With their ability to create highly detailed and customizable objects, inkjet printers are an essential part of the evolving world of 3D printing technology.

FAQ

What is the advantage of using a 3D inkjet printer for PCB manufacturing?

3D inkjet printers offer high resolution and smooth surface finishes for accurate and optimal performance of printed circuit boards.

Can inkjet printers deposit both conductive and insulating materials?

Yes, inkjet printers can deposit both conductive and insulating materials using multiple printheads and a layer-by-layer process.

Does inkjet printing have limitations in terms of material range?

Yes, inkjet printing has limitations on the range of materials that can be used, primarily due to viscosity requirements. However, advancements in conductive and insulating materials are expected to expand the capabilities of 3D inkjet printing.

Are 3D-printed parts as mechanically strong as traditionally manufactured boards?

No, 3D-printed parts may have lower mechanical strength compared to traditionally manufactured boards. It is important to consider the mechanical strength requirements for specific applications.

What is PolyJet technology and how does it enhance inkjet printing?

PolyJet technology is a type of 3D printing that utilizes multi-material jetting photopolymer printing. It allows for the creation of complex geometries, intricate details, full-color combinations, transparencies, and flexible parts in a single model, enhancing the versatility and precision of inkjet printing.