Extruder 3D Printer Vs Others: A Detailed Comparison

Originally posted on December 14, 2023 @ 8:22 pm

This all-inclusive comparison manual will examine the differences between extruders used in 3D printing and other varieties of extruders.

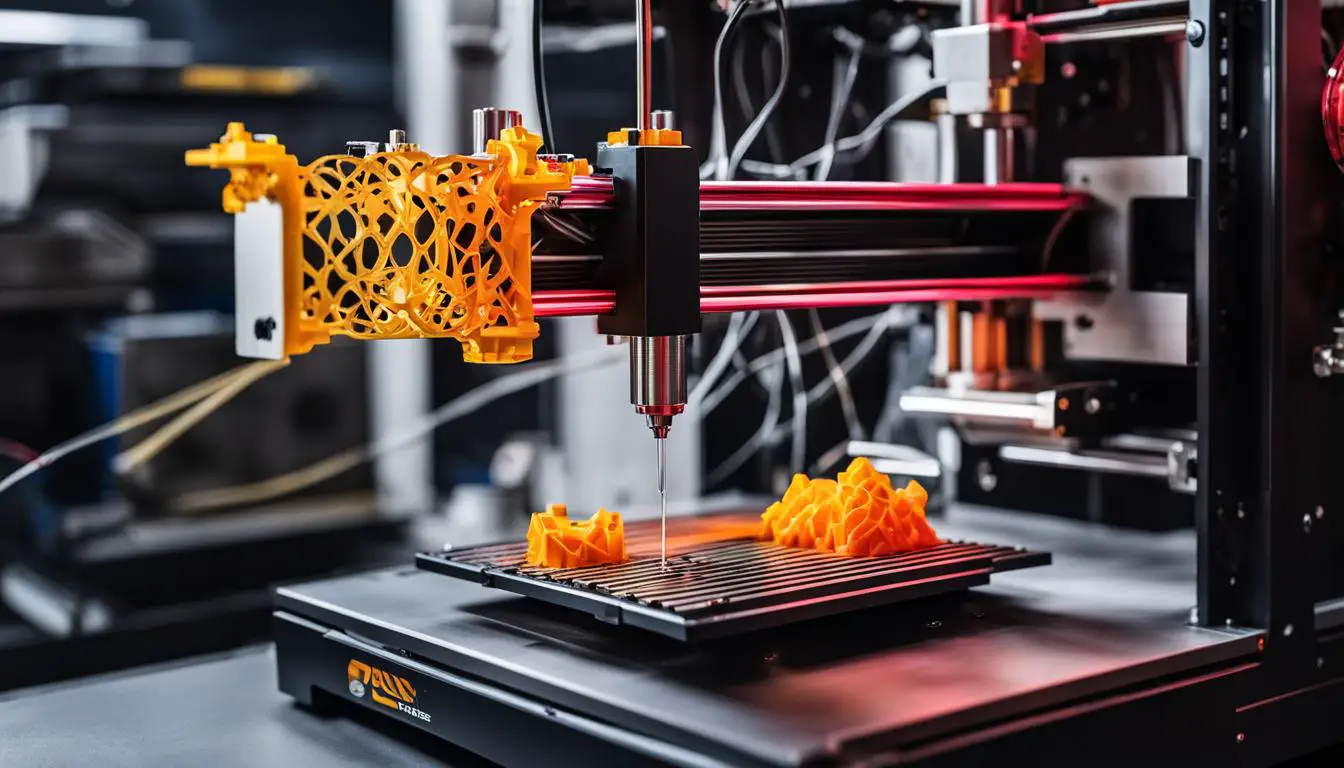

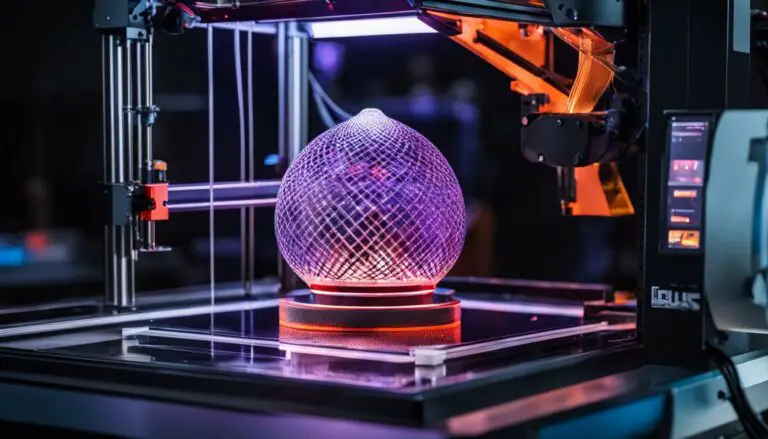

At the heart of every 3D printer lies the extruder, responsible for feeding the filament and pushing it through the nozzle. However, not all extruders are created equal. From basic feeders to advanced designs with dual gears and worm drives, extruders come in a variety of forms and shapes. Understanding the differences between them is crucial for achieving optimal printing results.

Throughout this guide, we’ll delve into various factors that set extruder 3D printers apart from others, including extrusion force, weight, maintenance, filament compatibility, and more. Whether you’re a small-scale injection molding enthusiast or a high-speed printing enthusiast, this detailed comparison will help you make an informed decision when choosing the best extruder for your 3D printing needs.

Key Takeaways:

- Extruders for 3D printers come in different forms, from basic feeders to advanced designs.

- Understanding the distinctions between extruder 3D printers and other types is crucial for optimal printing results.

- Factors to consider include extrusion force, weight, maintenance, filament compatibility, and more.

- Make an informed decision based on your specific needs and preferences.

- Stay tuned for the following sections to explore the types of extruders, comparison of specific models, and their pros and cons.

Types of Extruders for 3D Printers

When it comes to 3D printing, the type of extruder you choose plays a crucial role in determining the quality and performance of your prints. There are two main types of extruders commonly used in 3D printers: direct extruders and Bowden extruders. Each type has its own set of advantages and considerations that you should be aware of before making a decision.

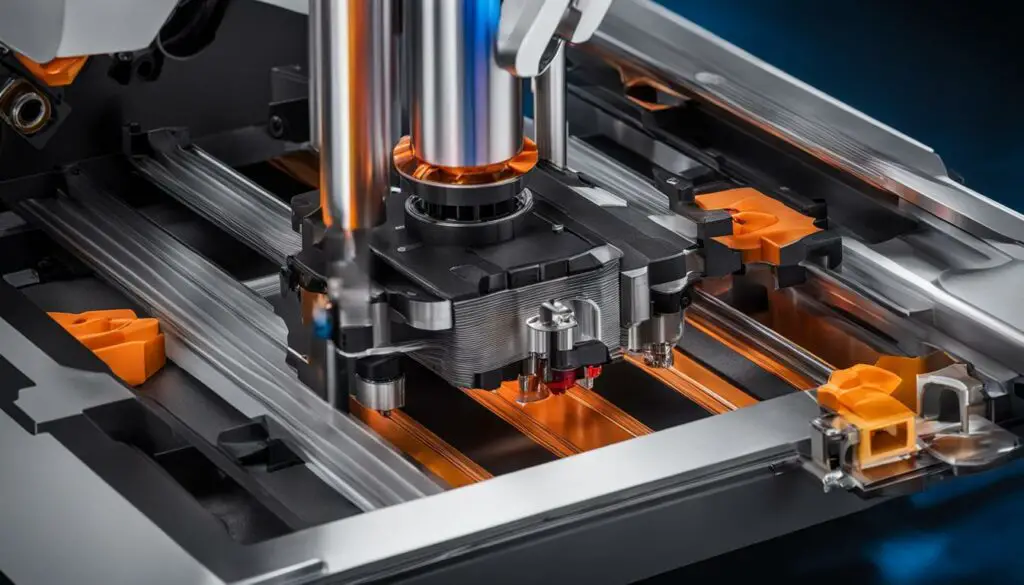

Direct Extruder

The direct extruder is mounted on the print head and pushes the filament directly into the nozzle. This design offers several benefits, including better extrusion control and faster retraction, resulting in cleaner and more accurate prints. Direct extruders are also known for their versatility when it comes to filament compatibility, allowing you to work with a wide range of materials, including flexible and abrasive filaments.

Bowden Extruder

In contrast, the Bowden extruder is attached to the frame of the printer and uses a long PTFE tube to guide the filament to the hotend. This design reduces the weight on the print head, resulting in smoother movements and less vibration during printing. However, Bowden extruders require more powerful motors to control the filament due to the longer path it needs to travel, and they may have limitations when it comes to printing with flexible filaments.

Ultimately, the choice between a direct extruder and a Bowden extruder depends on your specific needs and preferences. If you prioritize precise extrusion control and versatility with different filaments, a direct extruder may be the better option for you. On the other hand, if you value lightweight design and reduced vibrations, a Bowden extruder might be the right choice. Consider your printing requirements and weigh the pros and cons of each type before making a decision.

Comparison of Direct Extruders

Direct extruders are a popular choice for 3D printers due to their proximity to the nozzle, allowing for better extrusion and compatibility with a wide range of filaments. The extrusion force of direct extruders enables faster retraction, resulting in cleaner prints with reduced stringing. These extruders are capable of handling various filament types, including flexible and abrasive materials, making them versatile for different printing needs.

However, it’s important to consider some drawbacks of direct extruders. The additional weight of the extruder on the print head can increase power requirements and put more strain on the printer’s components. This extra weight can also impact the overall speed of the printer, potentially slowing down the printing process. Maintenance can be more complex with direct extruders, particularly when it comes to cleaning the nozzle, which requires disassembly and thorough cleaning to ensure optimal performance.

Despite these considerations, direct extruders remain a popular choice for many 3D printer enthusiasts due to their extrusion capabilities and filament compatibility. They offer a reliable and efficient solution for producing high-quality prints with a wide variety of materials.

Direct Extruder Comparison Table

| Model | Extrusion Force | Filament Compatibility | Maintenance |

|---|---|---|---|

| Bondtech BMG | High | Wide range of filaments, including flexible | Requires disassembly for nozzle cleaning |

| E3D Hemera | Moderate | Limited customization, supports various filaments | Standard maintenance required |

| Orbiter 2.0 | High | Good performance with flexibles | Standard maintenance required |

| Sherpa Mini | Moderate | Supports flexible filaments | Standard maintenance required |

| Bondtech LGX | High | Improved filament grip | Standard maintenance required |

Table: Comparison of Direct Extruder Models

Comparison of Bowden Extruders

In this section, we will compare Bowden extruders, which are a popular type of extruder commonly used in 3D printers. Bowden extruders have their unique advantages and disadvantages that make them suitable for specific printing needs. Let’s explore the key factors that differentiate Bowden extruders from other types and understand their impact on printing performance.

Filament Pushing Force

One of the critical aspects to consider when comparing extruders is the filament pushing force. Bowden extruders rely on a long PTFE tube to guide the filament to the hotend, resulting in reduced pushing force compared to direct extruders.

This lower pushing force can affect the extrusion consistency, especially when printing with flexible or abrasive filaments. The filament may not be pushed as effectively, leading to potential underextrusion or uneven layer deposition. However, with the right settings and tuning, Bowden extruders can still produce high-quality prints.

Filament Compatibility

Another consideration is the filament compatibility of Bowden extruders. Due to the longer filament path and reduced pushing force, Bowden extruders may have limitations when it comes to printing flexible filaments. The increased distance between the extruder and hotend can cause issues with filament bending or buckling, affecting print quality.

However, Bowden extruders excel in printing rigid filaments such as PLA or ABS, offering reliable performance and consistent results. If your printing needs primarily involve rigid filaments, a Bowden extruder can be a suitable choice.

Response Time

Bowden extruders have a slower response time compared to direct extruders. This delay is due to the longer filament path and the time it takes for the filament to travel through the PTFE tube. As a result, Bowden extruders may have limitations when it comes to printing models with intricate details or small features that require quick and precise extrusion movements.

Despite this drawback, Bowden extruders are still capable of producing high-quality prints with decent speed and accuracy, provided that the appropriate print settings are used.

Summary

In summary, Bowden extruders offer certain advantages such as reduced weight on the print head, resulting in cleaner movements, increased printing speed, and reduced vibrations. However, they may have limitations when it comes to filament pushing force, filament compatibility (especially with flexible filaments), and response time. It is important to consider your specific printing needs and find the right balance between these factors when selecting an extruder for your 3D printer.

Now that we have explored the distinctions between Bowden extruders and other types of extruders, let’s move on to the next section where we compare specific extruder models to help you make an informed decision.

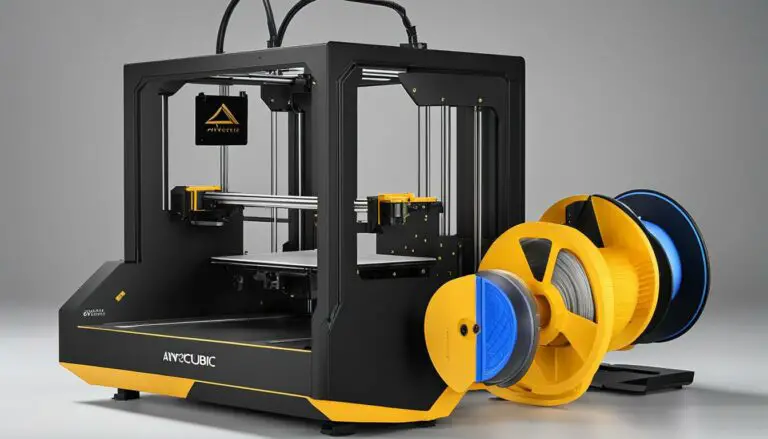

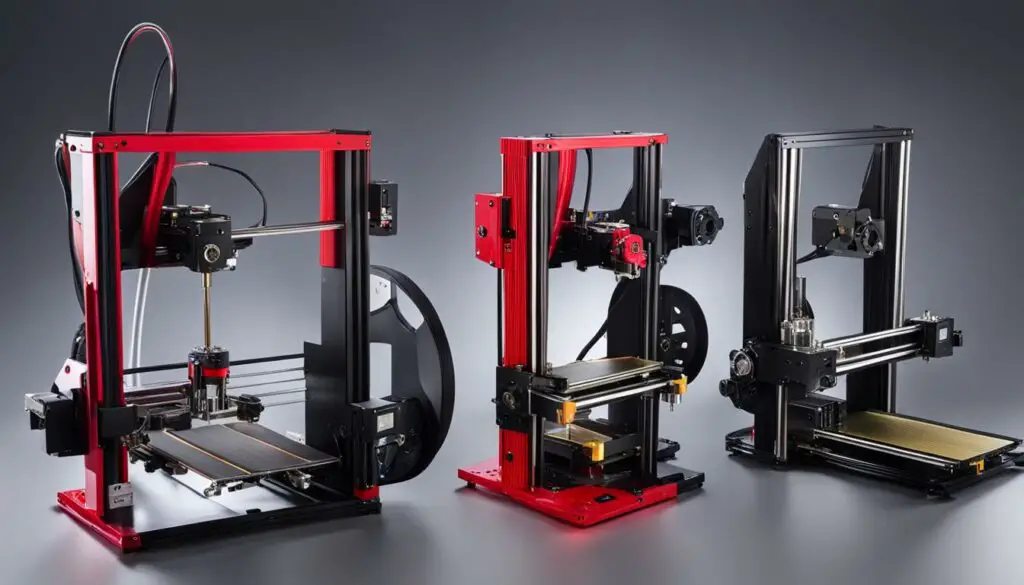

Comparison of Specific Extruder Models

When it comes to choosing the right extruder for your 3D printer, there are several specific models that stand out in terms of performance, reliability, and compatibility. In this section, we will compare and analyze some of the most popular extruder models on the market, including the Bondtech BMG, E3D Hemera, Orbiter 2.0, Sherpa Mini, and Bondtech LGX.

Bondtech BMG

The Orbiter 2.0 is known for its high filament pushing force, thanks to its planetary gearbox design. This extruder offers exceptional performance with flexible filaments, ensuring accurate and reliable printing results. If you frequently work with flexible materials, the Orbiter 2.0 can be a great choice to enhance your 3D printing experience.

Sherpa Mini

The Sherpa Mini is a lightweight and compact extruder that utilizes Bondtech BMG components. It delivers reliable filament feeding and excellent grip, making it suitable for a wide range of 3D printing applications. The Sherpa Mini is particularly popular among users who prioritize weight reduction and compact design without compromising performance.

Bondtech LGX

The Bondtech LGX stands out with its larger drive gears, providing improved filament grip and extrusion consistency. This extruder is designed to handle high torque applications, making it an excellent choice for demanding 3D printing projects. With its robust construction and reliable performance, the Bondtech LGX is a top-rated extruder among professionals and enthusiasts alike.

Each of these extruder models offers unique features and advantages, catering to specific needs and preferences. By considering factors such as grip, filament compatibility, performance, and reliability, you can select the best extruder for your 3D printing requirements.

Pros and Cons of Direct Extruders and Bowden Extruders

When it comes to choosing the right extruder for your 3D printer, there are two main options to consider: direct extruders and Bowden extruders. Each type has its own pros and cons, and understanding them can help you make an informed decision that suits your specific needs and preferences.

Direct Extruders:

Direct extruders, as the name suggests, are mounted directly on the print head of the 3D printer. This proximity to the hotend offers several advantages. One of the main benefits is better extrusion, as the filament is pushed directly into the nozzle. This allows for faster retraction and makes direct extruders more compatible with a wide range of filaments, including flexible and abrasive materials.

However, direct extruders also have their drawbacks. The extra weight of the extruder on the print head can increase power requirements and wear on components, ultimately leading to reduced printing speed. Additionally, maintenance, such as cleaning the nozzle, can be more complex with direct extruders.

Bowden Extruders:

Bowden extruders, on the other hand, are mounted on the frame of the 3D printer, with a long PTFE tube guiding the filament to the hotend. This design reduces the weight on the print head, resulting in cleaner movements, increased printing speed, and reduced vibrations.

However, Bowden extruders have their limitations. They require more powerful motors to control the filament due to the longer path through the tube, which can affect their response time. Bowden extruders are also less compatible with flexible and abrasive filaments compared to direct extruders.

Table: Pros and Cons of Direct Extruders and Bowden Extruders

| Pros | Cons | |

|---|---|---|

| Direct Extruders | – Better extrusion – Compatibility with various filaments – Faster retraction |

– Increased power requirements – Wear on components – Reduced printing speed – Complex maintenance |

| Bowden Extruders | – Reduced weight on print head – Cleaner movements – Increased printing speed – Reduced vibrations |

– More powerful motors required – Slower response time – Less compatibility with flexible and abrasive filaments |

Ultimately, the choice between direct extruders and Bowden extruders depends on your specific printing requirements. If you prioritize better extrusion and compatibility with various filaments, direct extruders might be the better option for you. On the other hand, if reducing weight and vibrations while increasing printing speed is your priority, Bowden extruders might be the way to go. Consider the pros and cons outlined above to make an informed decision and achieve the best results with your 3D printer.

Conclusion

When it comes to choosing the best extruder for your 3D printer, there are several factors to consider. Understanding the distinctions between extruder types and models is crucial in making an informed decision that meets your specific needs.

Direct extruders are known for their superior extrusion capabilities and compatibility with a wide range of filaments. They offer versatility and the ability to handle even flexible and abrasive materials. On the other hand, Bowden extruders are favored for their reduced weight and vibrations, resulting in cleaner movements and increased printing speed.

As you weigh your options, keep in mind that specific extruder models like the Bondtech BMG, E3D Hemera, Orbiter 2.0, Sherpa Mini, and Bondtech LGX each have their unique features and advantages. Consider factors such as extrusion force, weight, filament compatibility, and customization options to find the perfect fit for your 3D printing needs.

At Print Chomp, we strive to provide practical tips, how-to guides, and unbiased reviews. Our recommendations are backed by rigorous testing and research, ensuring you have the information you need to make the best choice. Happy printing!

FAQ

What are the main types of extruders used in 3D printers?

The main types of extruders used in 3D printers are direct extruders and Bowden extruders.

What is the difference between direct extruders and Bowden extruders?

Direct extruders are mounted on the print head and push the filament directly into the nozzle, while Bowden extruders are attached to the frame of the printer and use a long PTFE tube to guide the filament to the hotend.

What are the advantages of direct extruders?

Direct extruders offer better extrusion, faster retraction, and compatibility with a wide range of filaments, including flexible and abrasive materials.

What are the advantages of Bowden extruders?

Bowden extruders reduce weight and vibrations, resulting in cleaner movements, increased printing speed, and they are less prone to wear on components.

Which extruder models have been tested and compared?

Various extruder models have been tested and compared, including the Bondtech BMG, E3D Hemera, Orbiter 2.0, Sherpa Mini, and Bondtech LGX.

What are the pros and cons of direct extruders?

Direct extruders offer better extrusion and compatibility with various filaments, but their additional weight can lead to power requirements and reduced printing speed.

What are the pros and cons of Bowden extruders?

Bowden extruders reduce weight and vibrations but require more powerful motors and have limitations with flexible filaments.