Master Arduino Stepper Speed with 28YBJ-48 ULN2003

Originally posted on January 14, 2024 @ 11:09 pm

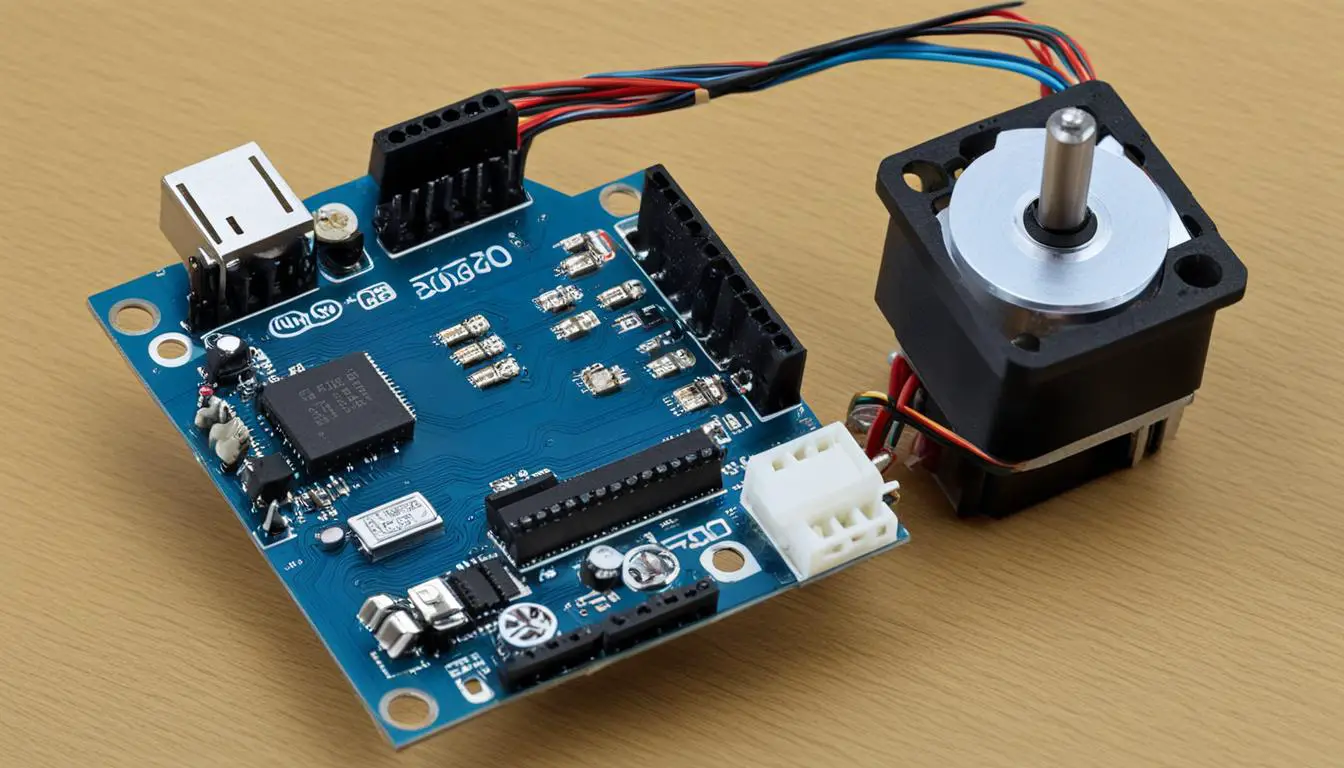

We are pleased to present our comprehensive guide for achieving precise speed control of the 28YBJ-48 stepper motor and the ULN2003 driver board with Arduino. These versatile motors are widely utilized in a variety of applications such as window blinds, 3D printers, DVD players, and CNC machines. With the proper components and understanding, you can effectively utilize the precision and control of these motors for your own projects. This article will examine the 28YBJ-48 stepper motor, the ULN2003 driver board, and the optimal methods for utilizing them with Arduino to achieve accurate speed control.

Key Takeaways:

- The 28YBJ-48 stepper motor with the ULN2003 driver board is commonly used for precise motion control.

- Stepper motors operate in discrete steps and require a driver board for control.

- Arduino can be used to control stepper motors using libraries like Arduino Stepper Library or AccelStepper Library.

- The 28YBJ-48 stepper motor operates on 5V and delivers good torque, but consumes power even when stationary.

- The ULN2003 driver board provides high current and voltage capability to drive the stepper motor.

How Stepper Motors Work

Stepper motors are fascinating devices that operate using a combination of electromagnets and a cogged wheel. Unlike traditional motors that use continuous rotation, stepper motors move in precise and fixed angle increments known as steps.

When it comes to controlling the speed and direction of a stepper motor, the sequence and frequency of pulses sent to the coils play a crucial role. By energizing the coils in the correct sequence, the motor rotates smoothly and precisely.

To harness the power of stepper motors with Arduino, there are handy libraries available, such as the Arduino Stepper Library and the AccelStepper Library. These libraries handle the stepping sequence, making it easy to control both unipolar and bipolar stepper motors with Arduino.

“Stepper motors allow us to achieve precise and controlled movements, making them ideal for applications that require accurate positioning, such as robotics, 3D printers, and CNC machines.”

Understanding the fundamentals of how stepper motors work and how to control them is crucial for any Arduino enthusiast or hobbyist looking to embark on exciting projects involving motor control.

Arduino Stepper Library

The Arduino Stepper Library is a powerful tool for controlling stepper motors with Arduino. It provides functions that simplify the process of configuring and controlling the motor’s speed, direction, and steps.

With the Arduino Stepper Library, you can easily set the motor speed, set the number of steps per revolution, and even control multiple motors simultaneously.

AccelStepper Library

If you’re looking for more advanced features and capabilities, the AccelStepper Library is an excellent choice. This library not only allows you to control stepper motors but also provides acceleration and deceleration functions to achieve smooth and precise movements.

With the AccelStepper Library, you can implement acceleration profiles, create complex motion patterns, and even synchronize multiple motors with different stepping speeds.

By leveraging the power of these libraries, arduino motor control becomes a breeze, providing endless possibilities to create intricate and dynamic stepper motor movements.

| Advantages of Stepper Motors | Disadvantages of Stepper Motors |

|---|---|

| High precision and accuracy | Higher power consumption compared to other motor types |

| Ability to hold position when not moving | Lower maximum speed compared to other motor types |

| No additional feedback sensors required | Noisy operation at high speeds |

| Simple control interface with step and direction signals | Higher cost compared to DC motors |

The 28BYJ-48 Stepper Motor

The 28BYJ-48 stepper motor is a small-sized motor that operates on 5V and is commonly used in various applications. It features five wires and two coils, each with a center tap, enabling precise control over its movements. The motor has a gear reduction ratio of 64:1, resulting in 2048 steps per revolution. This fine-grained control allows for accurate positioning and smooth motion in projects that require precise movement.

The 28BYJ-48 stepper motor provides good torque, even when at a standstill, making it suitable for applications requiring holding strength or resistance to external forces. It consumes approximately 240 mA of power, which should be taken into consideration when designing the power supply for your project.

When connecting the 28BYJ-48 stepper motor to an Arduino, it can be powered directly from the Arduino’s 5V output. However, to ensure optimal performance and avoid electrical noise on the Arduino’s power supply lines, it is recommended to use an external 5V power supply.

With its compact size, precise control, and reliable performance, the 28BYJ-48 stepper motor is a versatile choice for various projects that require accurate motion control.

| Specifications | Value |

|---|---|

| Operating Voltage | 5V |

| Number of Wires | 5 |

| Number of Coils | 2 (each with a center tap) |

| Gear Reduction Ratio | 64:1 |

| Steps per Revolution | 2048 |

| Power Consumption | Approximately 240 mA |

The ULN2003 Driver Board

When it comes to controlling the 28BYJ-48 stepper motor, the ULN2003 driver board plays a crucial role. This board is specifically designed to handle the power consumption of the motor, ensuring its smooth and efficient operation. Let’s take a closer look at the ULN2003 driver board and its features.

The ULN2003 driver board is equipped with seven Darlington transistor pairs, each capable of driving a load of up to 500mA and 50V. These transistor pairs provide the necessary current amplification and voltage switching required to control the stepper motor effectively. With four control inputs and a power supply connection, the board enables precise control of the motor’s movement and speed.

To provide users with visual feedback, the ULN2003 driver board also includes LEDs that indicate the stepping activity. These LEDs give a clear indication of the motor’s operation, allowing users to monitor its performance in real-time.

Connecting the ULN2003 driver board to the Arduino is a straightforward process. The board requires four control input pins and a common ground connection to establish communication with the Arduino. By establishing this connection, users can send commands to the motor and control its rotation, speed, and direction based on their specific requirements.

It is important to note that the ULN2003 driver board requires a suitable power supply to operate effectively. While the motor can be powered directly from the Arduino, it is recommended to use an external 5V power supply to ensure stable and reliable performance. This external power supply helps prevent any electrical noise or interference on the Arduino’s power supply lines, allowing for optimal motor control.

Overall, the ULN2003 driver board is a crucial component in stepper motor control systems, providing the necessary voltage and current amplification as well as seamless communication with the Arduino. It simplifies the process of controlling the 28BYJ-48 stepper motor, allowing users to achieve precise speed and smooth movement in their Arduino projects.

Conclusion

In conclusion, the 28BYJ-48 stepper motor with a ULN2003 driver board is an excellent choice for precision motion control projects. With the use of Arduino and the appropriate libraries, controlling the speed and direction of the stepper motor becomes a straightforward process. The affordability and reliability of these components make them ideal for hobbyists and professionals alike.

It is crucial to consider the power consumption of the 28BYJ-48 stepper motor. While it provides precise positioning and good torque, it does consume energy even when stationary. To ensure optimal performance, it is recommended to use an external 5V power supply to power the motor, minimizing electrical noise on the Arduino’s power supply lines.

By understanding the working principles and specifications of the 28BYJ-48 stepper motor and the ULN2003 driver board, users can confidently integrate these components into their projects. Whether you’re building a 3D printer, a CNC machine, or any other application that requires precise motion control, the combination of the 28BYJ-48 stepper motor and the ULN2003 driver board will help you achieve your goals.

FAQ

How do I control the speed of a stepper motor with Arduino and the 28BYJ-48 ULN2003 driver?

You can control the speed of a stepper motor with Arduino and the 28BYJ-48 ULN2003 driver by adjusting the timing between pulses sent to the motor. You can use the delay() function or the AccelStepper library to control the timing and achieve the desired speed.

Can I power the 28BYJ-48 stepper motor directly from the Arduino?

Yes, you can power the 28BYJ-48 stepper motor directly from the Arduino. However, it is recommended to use an external 5V power supply to avoid electrical noise on the Arduino’s power supply lines. This will ensure optimal performance and stability.

What are the specifications of the 28BYJ-48 stepper motor?

The 28BYJ-48 stepper motor operates on 5V and has a torque of 34.3 mN.m. It is a 5-wire unipolar motor with a gear reduction ratio of 64:1, resulting in 2048 steps per revolution. It consumes approximately 240 mA of power and provides good torque even at a standstill.

How does a stepper motor work?

A stepper motor uses a cogged wheel and electromagnets to rotate in precise and fixed angle increments known as steps. The motor’s spinning direction and speed are determined by the sequence and frequency of pulses sent to the coils. By energizing the coils in the correct sequence, the motor rotates.

What is the purpose of the ULN2003 driver board?

The ULN2003 driver board is used to control the 28BYJ-48 stepper motor because it consumes a significant amount of power. The board consists of seven Darlington transistor pairs that can handle high current and voltage. It provides power and control signals to the motor, ensuring smooth and accurate motion.