Best Glue for Bonding 3D Printed Parts

Originally posted on January 20, 2024 @ 4:17 am

Selecting the appropriate adhesive is essential for creating durable and secure bonds between 3D printed components. In our pursuit of finding the most effective glue for this task, we have assessed several options, including Weld-On #16, Epoxy, Polyurethane Glue, CA (Crazy Glue), All Purpose Goop, Plastic Model Cement, and Contact Cement.

The results of the testing revealed that Weld-On 16, CA (Superglue), and Contact Cement performed the best, with excellent bonds that held up even under force. Epoxy and Polyurethane Glue showed weaker bonds, which could be attributed to factors such as flexibility of the PLA pieces and surface preparation. Overall, the rougher the surfaces of the PLA parts were sanded and the more rigid the pieces, the better the glues performed. Weld-On 16, in particular, stood out as it actually melted the PLA, creating an incredibly strong bond. This glue, along with CA and Contact Cement, are recommended for bonding PLA to PLA.

Key Takeaways:

- Choosing the right glue is crucial for strong, lasting joints in 3D printed parts.

- Weld-On 16, CA (Superglue), and Contact Cement performed the best in our tests.

- Surface preparation and the flexibility of the PLA pieces can affect bond strength.

- Weld-On 16, CA, and Contact Cement are recommended for bonding PLA to PLA.

Testing Methodology for Bonding 3D Printed Parts

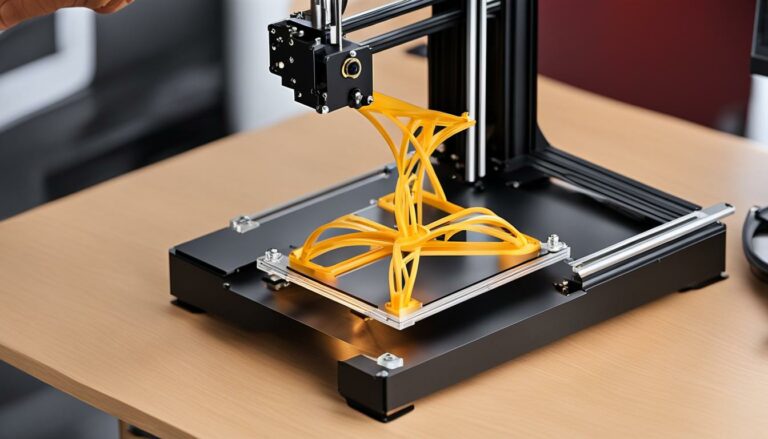

In order to determine the most effective bonding method for 3D printed parts, we conducted a comprehensive testing process. Our methodology involved printing flat pieces of PLA measuring 40mm x 20mm x 3mm, which were then used to evaluate the performance of different adhesives.

We divided the testing into two groups, one involving sanded PLA and the other unsanded PLA. By testing both surfaces, we aimed to assess how surface preparation impacted the bonding process. The pieces were glued together using various adhesives and were then clamped to ensure optimal contact and curing.

After allowing the glues to fully cure according to the manufacturer’s instructions, we conducted destructive testing to measure the strength of the bonds. This involved attempting to pull apart the bonded pieces and, if they held up, applying further force with a twisting and prying motion.

The speed at which the glue sets was also taken into account, as this can be a crucial factor when working with parts that cannot be clamped. We documented the curing times for each adhesive to better understand their practical application and limitations.

Through this comprehensive testing methodology, we were able to obtain valuable insights into the performance of different adhesives for bonding 3D printed parts. These findings will guide us in selecting the most effective bond glue for various applications and ensure the creation of strong, durable bonds between 3D printed components.

Adhesive Testing Results

| Adhesive | Bond Strength | Surface Preparation | Curing Time |

|---|---|---|---|

| Weld-On 16 | Excellent | Sanded PLA | Fast |

| CA (Superglue) | Excellent | Sanded PLA | Rapid |

| Contact Cement | Excellent | Unsanded PLA | Quick |

| Epoxy | Fair | Sanded PLA | Medium |

| Polyurethane Glue | Fair | Unsanded PLA | Slow |

Best Glue Types for Bonding 3D Prints

When it comes to bonding 3D prints, there are several glue types that can be effective. Let’s explore the different options:

- Cyanoacrylates (CA or Superglue): Cyanoacrylates are based on ethyl cyanoacrylate and are known for their quick-setting properties. They provide a strong bond and are suitable for most common 3D printed materials. However, they can be challenging to work with due to their quick curing time.

- Epoxy: Epoxy is another popular glue type, consisting of two components that need to be mixed before use. It provides a strong bond and can also be used to fill in holes or seams on 3D prints.

- Acetone: Acetone chemically melts the surface of 3D prints, resulting in a seamless bond. However, it is only compatible with ABS and HIPS materials.

- Hot Glue and 3D Pens: Hot glue guns and 3D pens are also viable options for bonding 3D prints. They offer solid bonds and easy application.

Each glue type has its own advantages and considerations, making it important to choose the right one for your specific needs. Whether you opt for cyanoacrylates, epoxy, acetone, or hot glue/3D pens, select the glue that best suits the materials you are working with and the desired strength of the bond.

| Glue Type | Advantages | Considerations |

|---|---|---|

| Cyanoacrylates (CA or Superglue) | Quick-setting, strong bond | Challenging to work with due to quick curing time |

| Epoxy | Strong bond, can fill holes and seams | Two components need to be mixed before use |

| Acetone | Chemically melts the surface, seamless bond | Only compatible with ABS and HIPS materials |

| Hot Glue and 3D Pens | Solid bonds, easy application | May not be suitable for all types of prints |

Preparation and Safety Tips for Bonding 3D Prints

Before bonding 3D prints, it is crucial to properly prepare the surfaces for the best results. Follow these essential tips to ensure a successful bonding process:

Cleaning the Surfaces

Begin by thoroughly cleaning the surfaces of the prints to remove any dirt, grease, or residues that could hinder the bond. Use a mild detergent or isopropyl alcohol solution to wipe the surfaces clean. This step is vital in ensuring a strong and lasting bond.

Sanding the Surfaces

If the surfaces of your 3D prints are rough or uneven, it is recommended to sand them using a fine-grit sandpaper. Sanding creates a smoother surface, increasing the adhesive’s contact area and improving the bond strength. After sanding, be sure to clean off any sanding dust.

Proper Ventilation

When working with bond glues, it is important to consider ventilation to minimize exposure to fumes. Many adhesives can have irritant or toxic effects. Work in a well-ventilated area or outdoors to ensure fresh air circulation. This simple precaution protects your respiratory system and promotes safer working conditions.

Safety Gloves

Wearing safety gloves is highly recommended to protect your skin from potentially harmful substances. Some glues may contain chemicals that can cause skin irritation or allergic reactions. Choose gloves made from materials that are resistant to the specific adhesive you are using. Safety gloves safeguard your hands and maintain personal safety during the bonding process.

By following these preparation and safety tips, you can ensure a smooth and secure bonding process for your 3D prints, minimizing risks and achieving optimal results.

Bonding Tips for Specific Filaments

When it comes to bonding 3D prints, understanding the compatibility of bond glues with different filaments is crucial for achieving strong and durable bonds. Let’s explore some bonding tips for specific filaments to help you make the right choice for your 3D printing projects:

Superglue

Superglue, also known as cyanoacrylate (CA), is a versatile adhesive that is compatible with most filaments, including ABS, PLA, PETG, and more. However, it may not be suitable for bonding flexible materials. The quick-setting properties of superglue make it ideal for creating strong bonds with rigid 3D prints.

Epoxy

Epoxy is a two-component adhesive that can be used with all filaments, including flexible materials. However, it’s important to note that epoxy can leave a rigid seam on flexible prints, which may affect their flexibility. Nevertheless, epoxy offers a strong bond and can be used not only for bonding but also for filling in holes or seams in 3D prints.

Acetone

Acetone is a solvent that chemically melts the surface of ABS and HIPS materials, creating a seamless bond. It’s ideal for bonding ABS and HIPS filament prints, providing a strong and reliable joint. However, it’s important to note that acetone is not compatible with other filaments, such as PLA or flexible materials.

Hot Glue Guns and 3D Pens

Hot glue guns and 3D pens are versatile tools that can be used with all rigid materials, including ABS, PLA, and PETG. These tools offer easy application and solid bonds, making them suitable for a wide range of 3D printing projects. Whether you need to bond multiple parts or make repairs, hot glue guns and 3D pens can provide efficient and effective bonding solutions.

By understanding the filament compatibility of different bond glues, you can choose the right adhesive for your specific 3D printing needs. Whether you’re working with ABS, PLA, flexible materials, or other filaments, there’s a bond glue out there that can help you achieve strong and durable bonds.

Conclusion

Bonding 3D printed parts is crucial for creating durable objects with strong joints. By carefully selecting the right bond glue and employing proper bonding techniques, you can ensure that your 3D prints withstand force and last over time.

After conducting extensive testing, we have identified Weld-On 16, CA (Superglue), and Contact Cement as the top options for bonding PLA to PLA. These adhesives consistently produced excellent bonds, even under pressure. However, when choosing the right bond glue for your 3D printing project, it is important to consider the specific requirements and filament compatibility.

To achieve successful bonding results, it is essential to follow proper surface preparation techniques, such as cleaning and sanding, to create a strong bond interface. Additionally, ensuring proper ventilation and adhering to safety guidelines will help protect your health during the bonding process.

In summary, by selecting the appropriate bond glue, understanding filament compatibility, employing effective bonding techniques, and prioritizing safety, you can achieve strong and durable joints in your 3D printed parts. This will result in high-quality objects that meet your specific project requirements and stand the test of time.

FAQ

Which glue is the best for bonding 3D printed parts?

The best glues for bonding 3D printed parts are Weld-On 16, CA (Superglue), and Contact Cement, as they provide excellent and strong bonds.

What was the testing methodology used for bonding 3D printed parts?

The testing involved printing flat pieces of PLA, gluing them using different adhesives, and performing destructive testing to evaluate the strength of the bonds.

What are the best glue types for bonding 3D prints?

The best glue types for bonding 3D prints are Cyanoacrylates (CA or Superglue), Epoxy, Acetone, Hot Glue, and 3D Pens. Each has its own advantages and considerations.

What preparation and safety tips should I follow for bonding 3D prints?

Properly clean the surfaces of the prints, sand rough and uneven surfaces, ensure proper ventilation, and wear safety gloves to protect your skin.

What are some bonding tips for specific filaments?

Superglue is compatible with most filaments, while Epoxy can be used with all filaments but may leave a rigid seam on flexible materials. Acetone is ideal for bonding ABS and HIPS materials. Hot glue guns and 3D pens can be used with all rigid materials such as ABS, PLA, and PETG.

How important is the glue selection and bonding technique for creating strong joints in 3D printed parts?

The glue selection and bonding technique play a crucial role in creating strong joints in 3D printed parts and ensuring their durability.