Understanding the Dangers of Laser Cutting

Originally posted on January 23, 2024 @ 2:39 am

Greetings and thank you for visiting our all-inclusive manual regarding the hazards of laser cutting and the significance of prioritizing laser cutter safety. The advancement of laser cutting technology has greatly impacted multiple industries, providing accuracy and productivity. Nevertheless, it is essential to be mindful of the potential dangers involved in this procedure in order to safeguard the safety of operators and the working environment.

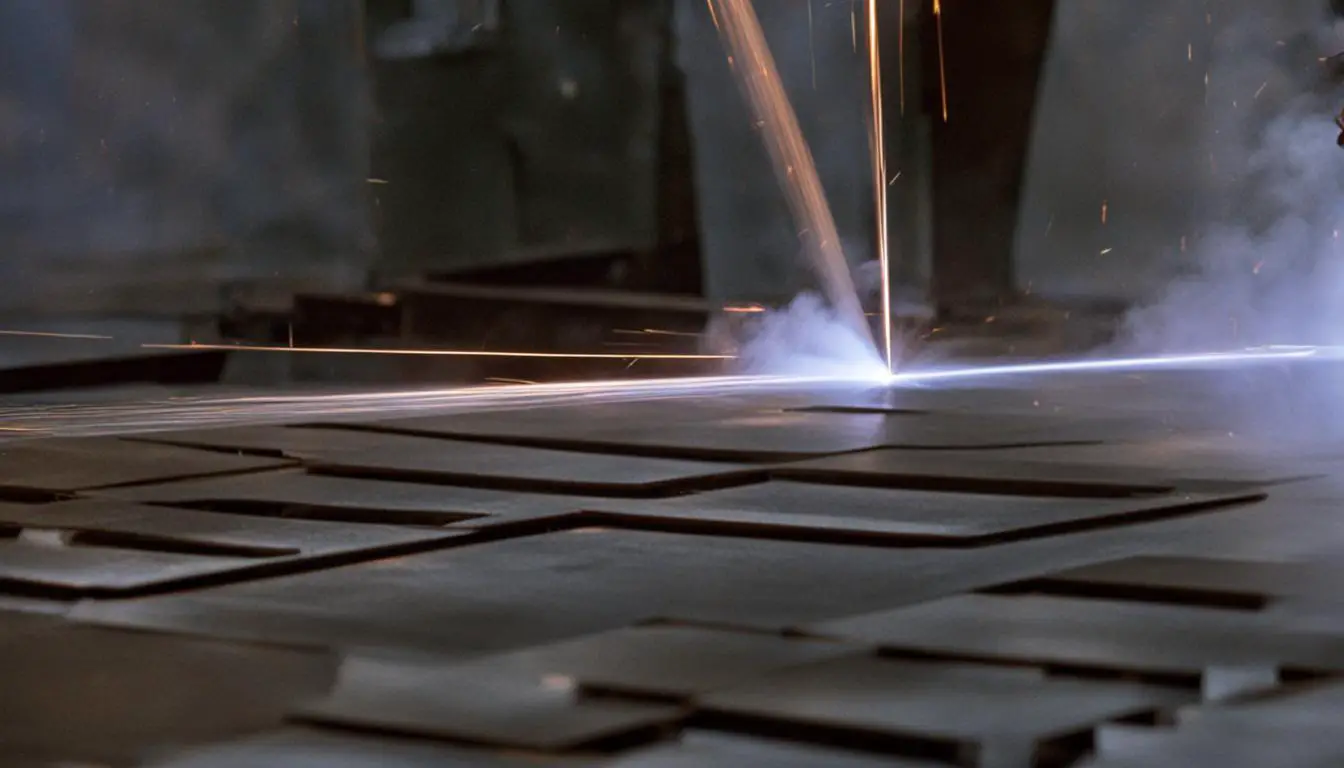

Laser cutting involves the use of high-energy laser beams that can pose significant risks if not properly controlled. These hazards include exposure to intense laser light, high temperatures that can lead to fires, and the release of toxic air contaminants. Understanding these risks and implementing appropriate safety measures is essential for safe and responsible laser cutter operation.

Key Takeaways:

- Exposure to high-energy laser light, high temperatures, and toxic air contaminants are the main dangers of laser cutting.

- Proper setup, training, operation, and engineering controls are necessary for safe laser cutter use.

- Understanding laser classifications, fire hazards, and air contaminant risks is crucial for ensuring safety in laser cutting environments.

- Proper personal protective equipment, maintenance, and adherence to safety guidelines are essential for safe laser cutter operation.

- Continuous education and adherence to best practices are key to minimizing the risks associated with laser cutting.

Laser Light Hazards

Laser cutting poses significant hazards, including the emission of high-energy laser light that can cause severe eye damage and skin burns.

Exposure to the laser beam can result in serious eye injuries, including blindness, if proper safety measures are not followed.

Moreover, the laser cutter classification system determines the level of risk associated with its use, ranging from Class 1 (low risk) to Class 4 (high risk).

To ensure safety when operating laser cutters, it is crucial to understand these classifications and implement appropriate safety measures.

Safety features, such as interlock switches, disable the laser when the doors are opened, minimizing the risk of exposure to the laser beam.

The table below provides an overview of the laser classifications and their corresponding hazards:

| Laser Class | Hazard Level |

|---|---|

| Class 1 | Lowest risk; laser is not hazardous under normal use |

| Class 2 | Low-power visible lasers that pose a low risk for eye injury |

| Class 3A | Moderate risk; capable of causing eye injury if viewed directly |

| Class 3B | High risk; can cause severe eye damage and skin burns |

| Class 4 | Highest risk; can cause significant harm to eyes and skin, as well as start fires |

Understanding the hazards associated with laser light and adhering to proper safety guidelines can help prevent accidents and protect both users and the surrounding environment.

Next, we will explore the fire hazards that can arise from laser cutting operations.

Fire Hazards

Laser cutters pose significant fire hazards due to the high temperatures and intense heat generated during cutting operations. These high temperatures can ignite flammable materials, leading to fires that can spread rapidly if not controlled. As a result, it is crucial to implement proper safety measures to prevent and control fires when working with laser cutters.

One key precaution is to ensure proper setup and maintenance of the laser cutter. Regular inspection and maintenance of the equipment can help identify and address any potential fire hazards. Additionally, it is important to establish a designated area for the laser cutter that is free from combustible materials. Keeping the workspace clean and clutter-free reduces the risk of accidental fires.

When cutting certain materials, fumes and smoke may be produced, further increasing the fire hazards. These fumes and smoke can be toxic and pose health risks if inhaled. Therefore, it is essential to have adequate ventilation systems in place to remove these hazardous byproducts. Regularly check and clean the ventilation system to maintain its effectiveness.

Fire extinguishers should be readily available near the laser cutter to immediately suppress any fire that may occur. It is crucial to select the appropriate type of fire extinguisher suitable for the potential fire risks involved. Proper training should also be provided to all personnel on how to safely use a fire extinguisher in case of an emergency.

Wearing personal protective equipment (PPE) is essential when working with a laser cutter. Protective clothing, such as fire-resistant gloves and aprons, can provide an additional layer of protection against potential fire hazards. Eye protection, such as laser safety goggles, should also be worn to shield the eyes from laser light and flying debris.

It’s important to remember that fire hazards associated with laser cutting can be effectively mitigated through proper setup, maintenance, and adherence to safety protocols. By proactively addressing these hazards, we can create a safer working environment when using laser cutters.

Air Contaminant Risks

Laser cutters produce various air contaminants, including fumes, vapors, and particulates, that can pose serious risks to both the machine and personal health. These contaminants can be highly toxic and require proper controls to minimize exposure. Additionally, it is crucial to ensure material compatibility to prevent the release of hazardous substances. Let’s explore these risks further and discuss the necessary precautions to protect against air contaminants in laser cutting operations.

Understanding the Risks

Laser cutting processes generate fumes, vapors, and particulates from the materials being cut. These byproducts can contain toxic substances that may have harmful effects on human health. Inhaling these air contaminants can lead to respiratory issues, skin irritations, and even long-term health complications.

Engineering Controls

To mitigate the risks associated with air contaminants, proper engineering controls must be in place. This includes the use of filtration and ventilation systems designed to remove or reduce the concentration of pollutants in the air. Effective filtration systems can capture and eliminate harmful particles, ensuring a safer working environment.

Material Compatibility

Material compatibility is another crucial aspect to consider when dealing with air contaminant risks. Some materials used in laser cutting can release hazardous substances when exposed to high temperatures. It is essential to ensure that the materials being processed are compatible with the laser cutter to minimize the release of toxic fumes and vapors.

“Effective engineering controls, such as filtration and ventilation systems, play a vital role in reducing exposure to air contaminants during laser cutting operations.”

By implementing robust engineering controls and ensuring material compatibility, the risks associated with air contaminants in laser cutting can be significantly reduced. This not only protects the well-being of operators but also extends the lifespan of the laser cutter itself.

Now that we have explored the risks associated with air contaminants in laser cutting, let’s move on to Section 5, where we will discuss the essential setup and use guidelines for safe laser cutter operation.

Laser Cutter Setup and Use

Proper setup and maintenance are essential for ensuring the safe operation of a laser cutter. During the installation process, it is crucial to follow manufacturer specifications to guarantee that the equipment is configured correctly. Regular maintenance and servicing are also important to identify and address any potential issues that may compromise safety.

However, proper setup and maintenance alone are not sufficient to ensure a safe working environment. Users must also receive adequate training on the potential hazards associated with laser cutting, as well as the necessary control measures, operating procedures, and the use of personal protective equipment (PPE). This training is crucial for preventing accidents and injuries and should be provided to all individuals who will be operating the laser cutter.

Safety Measures and Personal Protective Equipment

When using a laser cutter, certain safety measures should be followed to minimize risks. These precautions include:

- Wearing appropriate personal protective equipment (PPE), such as safety goggles and gloves, to protect against laser light hazards and potential skin burns.

- Ensuring proper supervision and guidance for inexperienced operators to prevent accidents.

- Choosing materials that are compatible with the laser cutter to avoid fires or the release of toxic fumes and particulates.

- Implementing safety guidelines provided by the manufacturer, such as maintaining a clean and clutter-free workspace.

- Properly cleaning the laser cutter after each use to remove any debris or residue that may affect its performance and safety.

- Reporting any incidents or safety concerns to the appropriate authorities.

Regular training, safety measures, and the proper use of personal protective equipment are crucial for maintaining a safe working environment when using a laser cutter.

| Safety Measures | Personal Protective Equipment (PPE) |

|---|---|

| Proper supervision and guidance for operators | Safety goggles |

| Choosing compatible materials | Gloves |

| Following manufacturer safety guidelines | |

| Cleaning the equipment after use | |

| Reporting incidents and concerns |

Best Practices for Safe Operation

When it comes to operating laser cutters, safe practices are of utmost importance. Following proper training and manufacturer instructions is crucial for ensuring a secure working environment. Here are some best practices to consider:

1. Training and Knowledge

Obtain comprehensive training on laser cutter operation and safety procedures. Familiarize yourself with the machine and its features to ensure safe and efficient usage.

2. Logbook Tracking

Keep a logbook to track the usage of the laser cutter. Record important details such as the materials used, cutting parameters, and maintenance activities. This logbook serves as a valuable resource for troubleshooting and maintenance purposes.

3. Fire Extinguisher Accessibility

Always have a fire extinguisher readily available near the laser cutter. In case of any fire incidents, immediate access to a fire extinguisher can help mitigate the situation and prevent further damage.

4. Regular Vacuuming

Regularly clean the laser cutter and its surroundings to remove debris and dust particles. Vacuuming the area helps prevent the accumulation of flammable materials, reducing the risk of fires.

5. Material Compatibility

Use only approved materials that are compatible with the laser cutter. Consult the manufacturer’s guidelines or seek expert advice to ensure the compatibility of the materials being used. Incompatible materials can lead to hazardous reactions and compromise the integrity of the machine.

6. Understanding Laser Settings

Be aware of the impact that laser settings can have on the likelihood of fires and the quality of cuts. Experiment and understand how different settings affect the outcome to achieve optimal results while maintaining safety precautions.

7. No Tampering with Safety Features

Do not tamper with or disable any safety features of the laser cutter. These safety features are implemented to protect both the operator and the machine from potential hazards.

8. Never Leave the Laser Cutter Unattended

Always remain near the laser cutter while it is in operation. Leaving the machine unattended can lead to unforeseen accidents or incidents that could have been prevented with immediate attention.

By following these best practices, you can ensure the safe operation of laser cutters, minimize risks, and maintain a secure working environment.

Laser Hazard Classification and Air Contaminants

In the world of laser cutting, understanding the hazards and risks associated with this powerful technology is paramount to maintaining a safe work environment. One crucial aspect of laser cutter safety is laser hazard classification, which determines the level of risk and precautions needed when using these machines.

When it comes to laser hazard classification, laser cutters are typically classified as Class 1 lasers. These lasers emit low levels of energy that are not considered hazardous to the eyes or skin. However, it’s important to note that Class 1 classification refers to the laser cutter as a whole.

Within the laser cutter, there may be enclosed lasers classified as Class 3B or Class 4. These lasers emit high levels of energy and pose significant risks to individuals if not properly controlled and managed.

Laser cutting processes can also produce Laser-Generated Air Contaminants (LGACs), which can be harmful if inhaled. LGACs consist of fumes, vapors, and particulates that are released during laser cutting operations. It’s essential to have proper filtration and ventilation systems in place to control and minimize the exposure to these contaminants.

Here is a breakdown of laser hazard classification and the associated risks:

| Laser Hazard Classification | Description |

|---|---|

| Class 1 | Lasers that emit low levels of energy, posing no hazards to the eyes or skin. |

| Class 2 | Visible lasers that can cause eye damage if directly viewed for extended periods. |

| Class 3A | Medium-powered lasers that can cause eye damage if viewed directly, but the risk is low. |

| Class 3B | Higher-powered lasers that can pose serious eye and skin hazards. |

| Class 4 | The highest-risk lasers that can cause immediate eye and skin damage, and also pose fire hazards. |

To ensure a properly functioning laser cutter and minimize the risks associated with laser cutting, it is crucial to invest in high-quality filtration and ventilation systems. These systems effectively remove LGACs from the air, protecting both the users and the equipment.

Note: Always consult the manufacturer’s specifications and recommendations regarding laser hazard classification, filtration, and ventilation systems for your specific laser cutter model.

Breathe Easy with Proper Filtration and Ventilation

Proper filtration and ventilation systems are essential components of laser cutter safety. These systems effectively remove harmful LGACs from the air, safeguarding the health and well-being of those operating the laser cutter.

Filtration systems use various mechanisms, such as activated carbon filters and high-efficiency particulate air (HEPA) filters, to capture and eliminate LGACs. The choice of filters depends on the specific contaminants generated during laser cutting operations.

Ventilation systems, on the other hand, help to create a controlled airflow that directs LGACs away from the operator’s breathing zone. This ensures that any generated contaminants are effectively captured and exhausted to the external environment.

By investing in quality filtration and ventilation systems, you can significantly reduce the risks associated with laser cutting, protect the health of your team, and prolong the lifespan of your laser cutter equipment.

Remember, safety first when it comes to laser cutting. Prioritize the proper laser hazard classification, filtration, and ventilation systems to promote a safe and healthy work environment for all.

Next, we will explore the importance of laser cutter setup and use, including training, safety measures, and personal protective equipment. Stay tuned!

Conclusion

Protecting against the dangers of laser cutting is of utmost importance in maintaining a safe work environment. By understanding the hazards involved, we can take the necessary precautions to minimize risks and ensure the well-being of all individuals involved in laser cutting operations.

Following laser cutter safety precautions, such as adhering to safety guidelines and obtaining proper training, is essential to mitigate potential hazards. This includes understanding the classifications of laser cutters and implementing appropriate safety measures based on these classifications. By doing so, we can prevent eye damage, skin burns, and other laser light hazards that may arise.

Additionally, it is vital to protect against fire hazards that can occur during laser cutting. Proper setup, maintenance, and the presence of fire extinguishers are crucial to prevent fires caused by high temperatures and combustible materials. Furthermore, controlling air contaminant risks through the use of engineering controls, such as filtration and ventilation systems, is necessary to reduce exposure to toxic fumes and protect both the machines and individuals from harm.

By prioritizing laser cutter safety and continuously educating ourselves on best practices, we can create a secure environment conducive to laser cutting operations. It is through our commitment to safety that we can effectively protect against the dangers associated with laser cutting and ensure the well-being of all individuals involved in the process.

FAQ

What are the dangers of laser cutting?

Laser cutting poses various hazards, including exposure to high-energy laser light, high temperatures that can cause fires, and toxic air contaminants.

What are the hazards associated with laser light?

Laser cutters emit a high energy laser beam that can cause severe eye damage, including blindness, and serious skin burns. It is important to understand the laser classifications and ensure proper safety measures are in place.

How can laser cutting create fire hazards?

Laser cutters produce high temperatures and significant heat while cutting, which can lead to fires. Some materials can catch fire during cutting operations, creating fumes and smoke. Proper setup, maintenance, and the use of fire extinguishers are essential to prevent and control fires.

What are the risks associated with air contaminants during laser cutting?

Laser cutters generate fumes, vapors, and particulates from substrates, which can be highly toxic. Proper engineering controls, such as filtration and ventilation systems, must be in place to control exposure. Material compatibility is also important to minimize the release of hazardous substances.

What precautions should be taken during laser cutter setup and use?

Proper installation, maintenance, and adherence to manufacturer specifications are essential for safe laser cutter setup. Users must undergo training on potential hazards, control measures, operating procedures, and the use of personal protective equipment (PPE). Supervision, proper material selection, and following safety guidelines during laser cutter use are crucial.

What are the best practices for safe operation of laser cutters?

Safe operation of laser cutters requires proper training and following manufacturer instructions. Keeping a logbook to track usage and materials is recommended. Having a fire extinguisher nearby, regular vacuuming to prevent fires, and using approved materials are essential best practices. It is also important to understand the impact of laser settings on the chance of fire and cut resolution.

What is the classification of laser cutters and how do they relate to air contaminants?

Laser cutters are typically classified as Class 1 lasers, which emit low levels of energy not hazardous to the eyes or skin. However, enclosed within the devices may be Class 3B or 4 lasers, which can emit high levels of energy and pose risks. Laser cutting can produce Laser-Generated Air Contaminants (LGACs), which may be hazardous. Proper filtration and ventilation systems must be used to control exposure and ensure a properly functioning laser cutter.

How can I protect against the dangers of laser cutting?

Understanding the dangers of laser cutting is crucial for maintaining a safe work environment. By following safety guidelines, obtaining proper training, and implementing necessary precautions, the risks associated with laser cutting can be minimized. It is essential to prioritize safety and take appropriate measures to protect against potential hazards.